Method and device for controlling flotation cell liquid level

A control method and flotation cell technology, applied in liquid level control, adaptive control, general control system, etc., can solve the problems of mutual influence, unstable flotation process, difficult to stabilize flotation process, etc., to achieve synergy control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

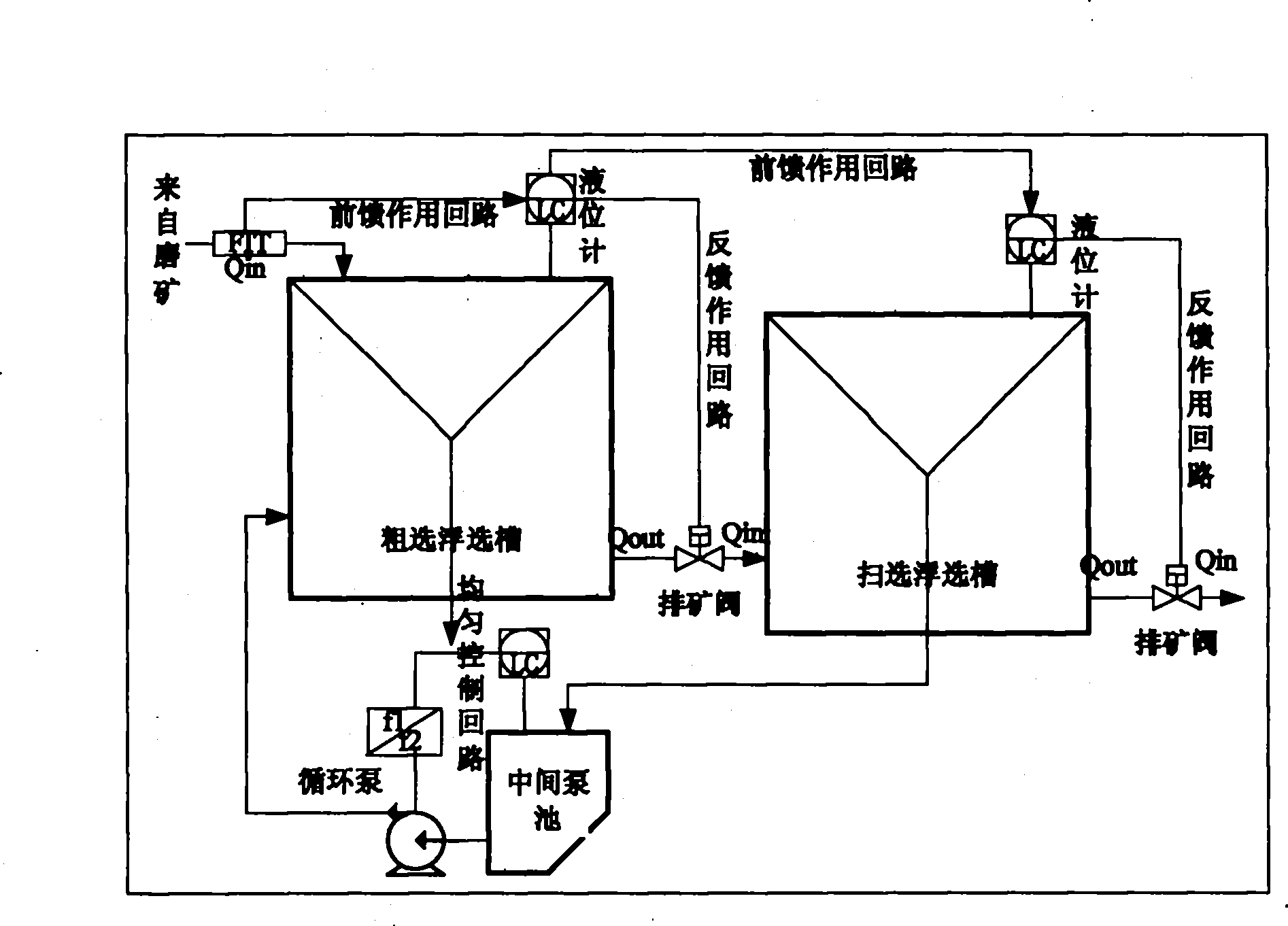

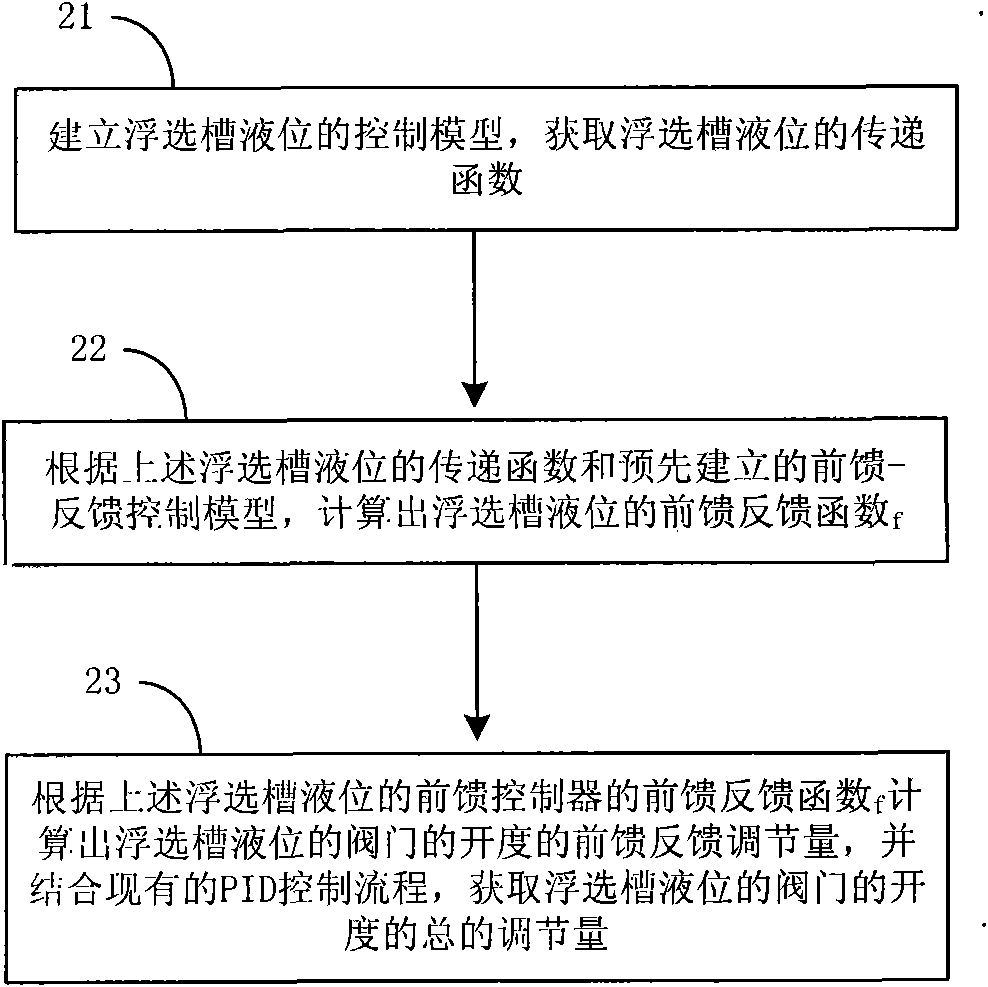

[0025] The schematic diagram of the principle of a method for controlling the liquid level of a flotation cell proposed in this embodiment is as follows figure 1 As shown, the processing flow of the control method is as follows figure 2 As shown, the following processing steps are included:

[0026] Step 21, establish the control model of the liquid level of the flotation cell, and obtain the transfer function H of the liquid level of the flotation cell i (s).

[0027] The interference source of the liquid level of the flotation tank mainly comes from the pulp flow entering the flotation, the flow of the circulating pump, and the opening degree change of the regulating valve.

[0028] First, establish the control model of the liquid level of the flotation cell, the control module mainly includes: the transfer function H of the liquid level of the flotation cell i (s), the H i (s) is calculated as follows:

[0029] H i ( ...

Embodiment 2

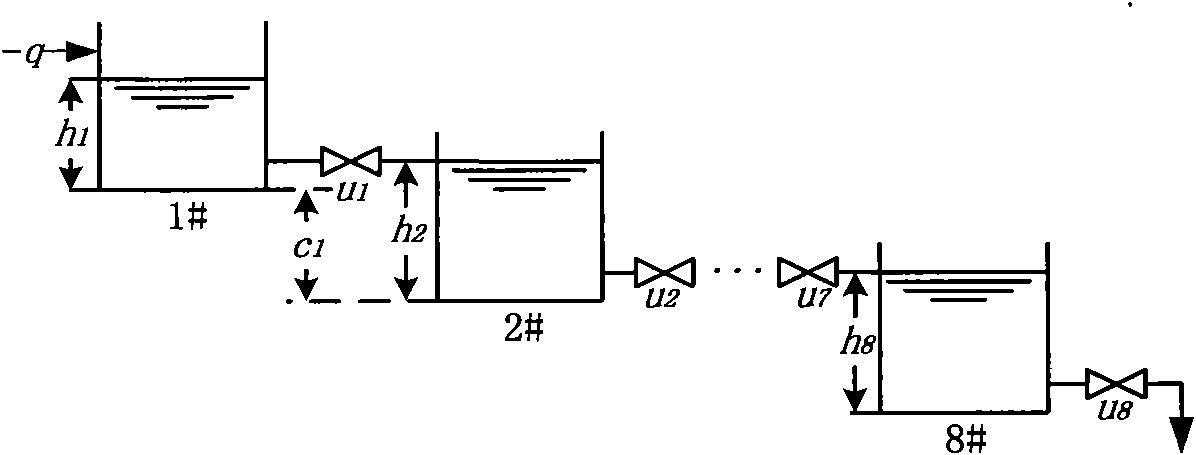

[0059] In practical applications, due to the characteristics of the flotation process, the impact of interference is transitive. In order to eliminate the impact of interference and ensure the stability of the flotation process, the feed-forward feedback function needs to be implemented at the correct time. The feed-forward feedback function If it is too early, it will easily cause new fluctuations, and if it is too late, it will not be able to counteract the influence of interference. Therefore, the embodiment of the present invention proposes a delay action algorithm, so that the feedforward feedback action can be implemented correctly.

[0060] The valve adjustments of the liquid levels of multiple flotation tanks are stored in sequence according to the set time intervals. After the time intervals corresponding to the adjustments of each valve arrive, the adjustments of each valve are sequentially taken out, and the valve adjustments are adjusted according to the taken out va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com