Lead frame and chip package

A technology of chip packaging and lead frame, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problem of reduced design flexibility of lead frames, and achieve the effect of large design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

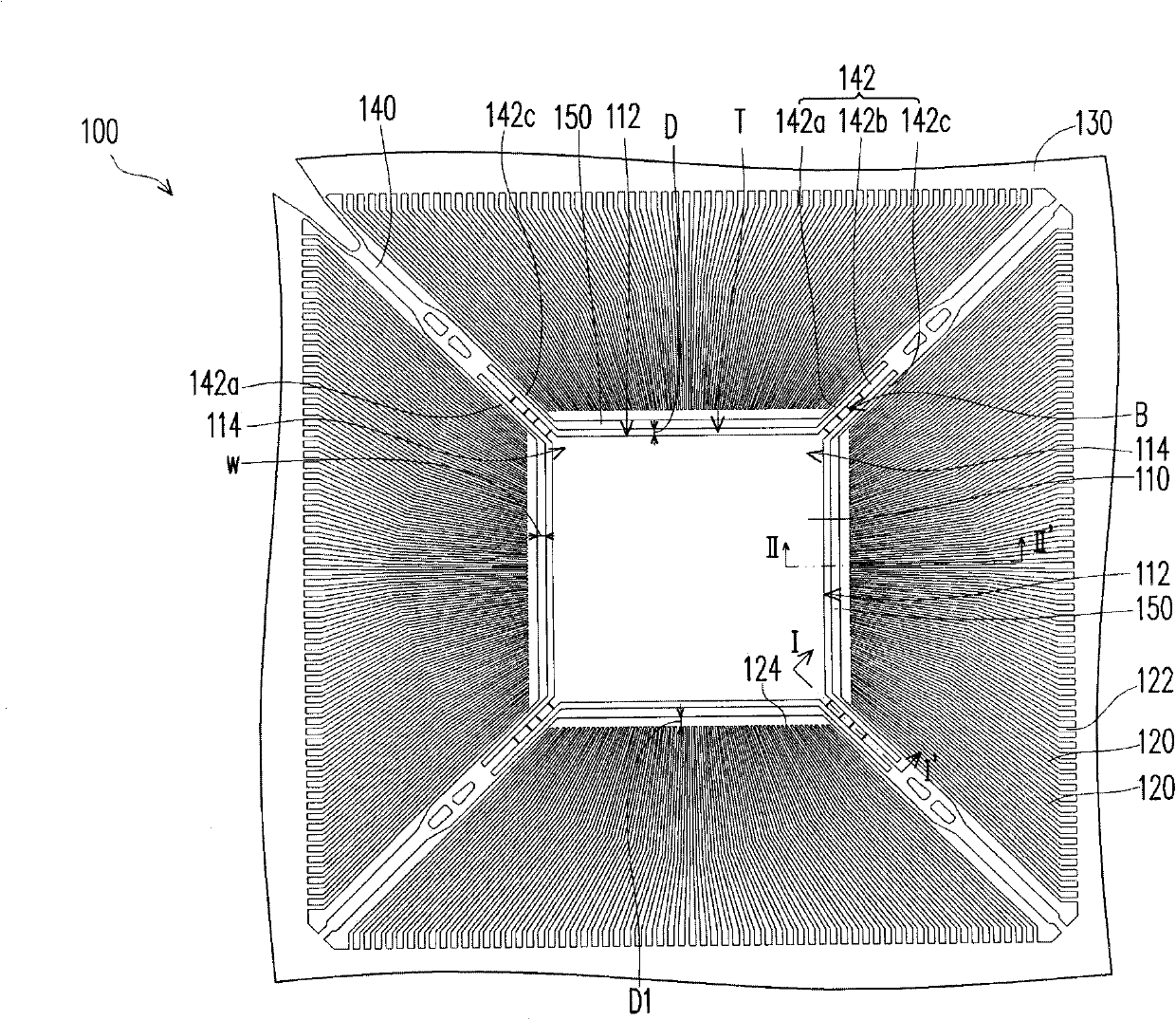

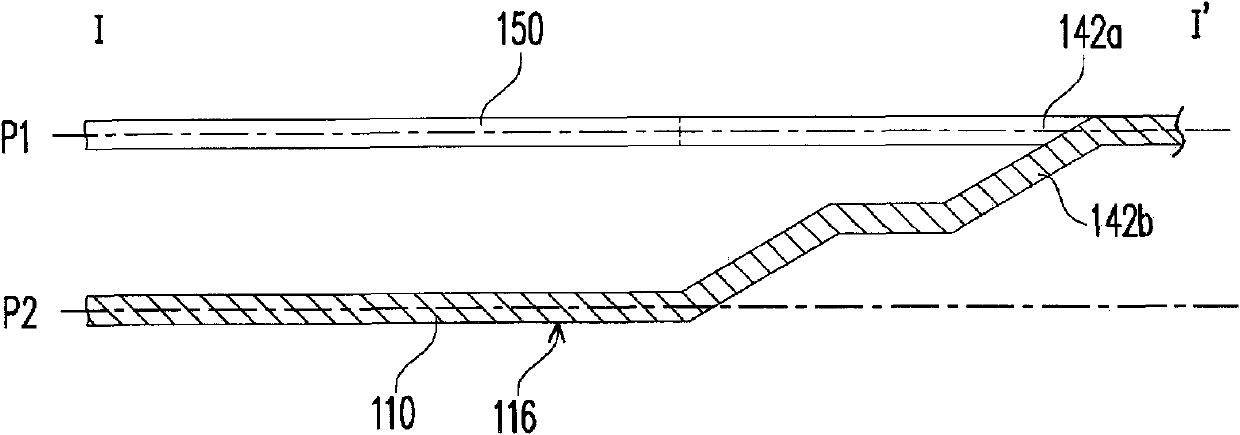

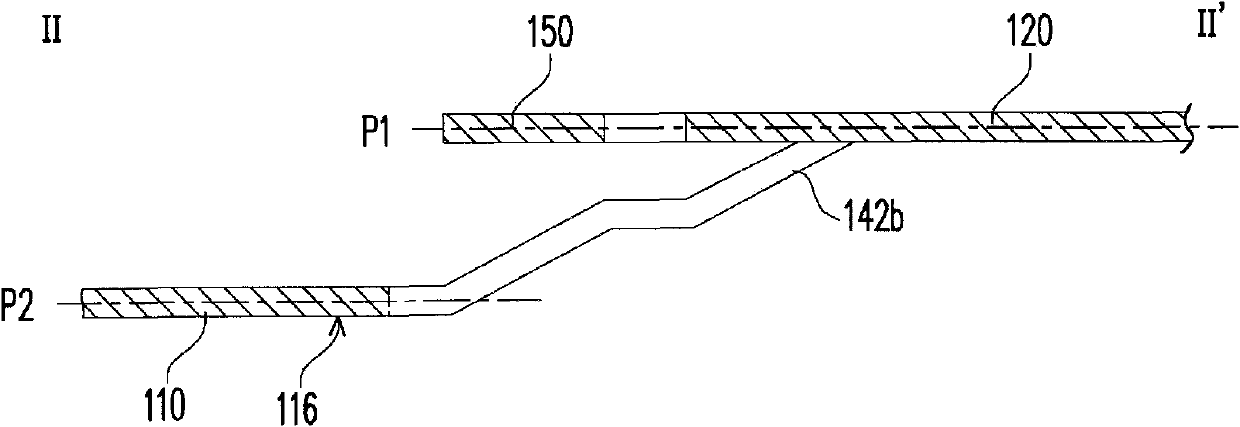

[0082] Figure 1A A top view of a lead frame according to an embodiment of the present invention is shown. Please refer to Figure 1A , the lead frame 100 of this embodiment includes a chip holder 110 , a plurality of pins 120 , an outer frame 130 , a plurality of connecting rods 140 and a plurality of grounding rods 150 . The pins 120 are arranged on the periphery of the chip holder 110, and the chip holder 110 and the pins 120 are arranged in the outer frame 130, wherein the end 122 of each pin 120 away from the chip holder 110 is connected to the outer frame 130, and each pin 120 One end 124 facing the die holder 110 is a free end.

[0083] Each connecting rod 140 is connected to the outer frame 130 and has an end portion 142 extending toward the die holder 110 . The end portion 142 has a first branch 142 a , a second branch 142 b and a third branch 142 c parallel to each other, wherein the second branch 142 b is located between the first branch 142 a and the third branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com