Anti-loosening terminal block and terminal assembly

A connection terminal and anti-loosening technology, which is applied in the direction of connection, electrical components, conductive connection, etc., can solve the problems of cumbersome procedures, inconvenient installation, and increased manufacturing costs, and achieve the effects of convenient maintenance, convenient installation, and prevention of electrical accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (Embodiment 1, anti-off terminal)

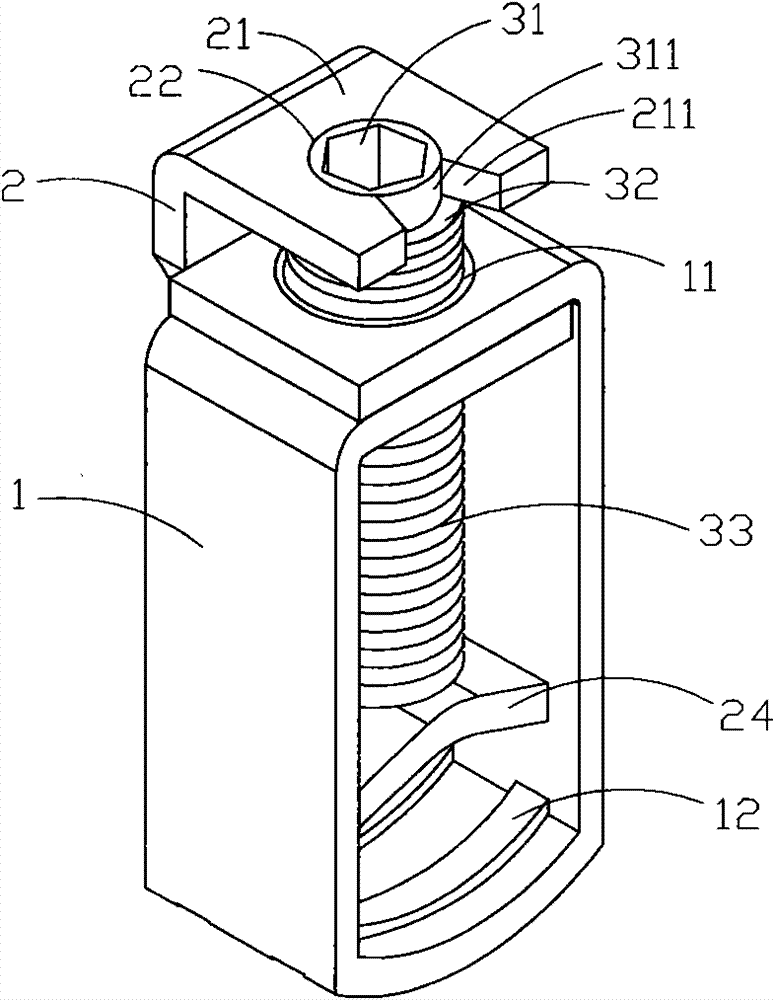

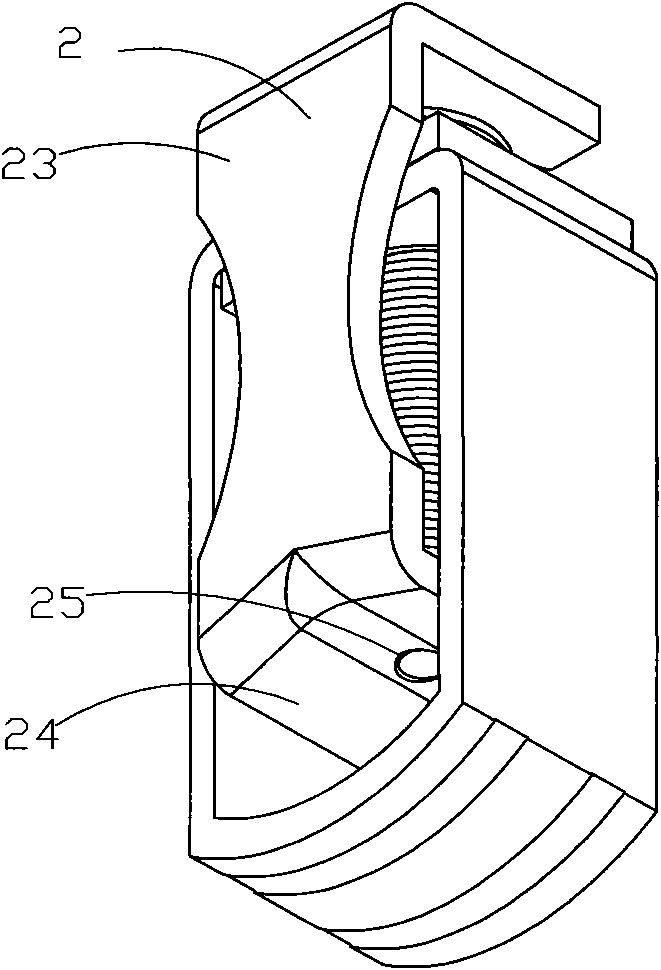

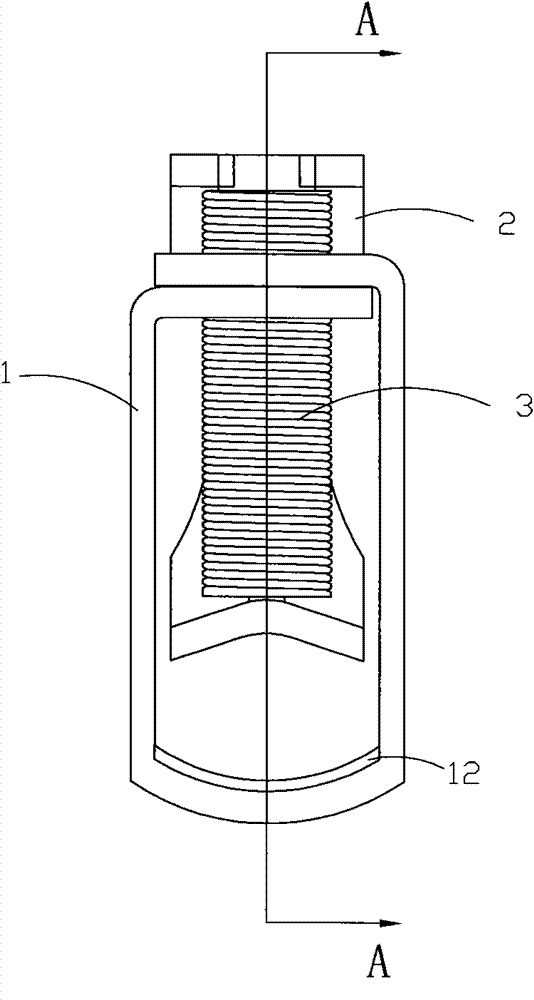

[0035] Figure 1 to Figure 4 A specific embodiment of the anti-off terminal in the present invention is shown, wherein figure 1 It is a three-dimensional schematic diagram of a structure of the anti-off terminal in the present invention; figure 2 yes figure 1 A schematic diagram of a three-dimensional structure of the anti-off terminal when viewed from another angle; image 3 yes figure 1 The front view of the anti-slip terminal block shown; Figure 4 yes image 3 The cross-sectional view of the anti-loosening terminal shown along the line A-A.

[0036] This embodiment is an anti-off terminal, see Figure 1 to Figure 4, including a metal frame 1 with through holes in the front and rear, a wire pressing piece 2 and an adjusting bolt; the top of the metal frame 1 is provided with a screw hole 11, and the adjusting bolt can rotate back and forth in the screw hole 11; it is characterized in that : The adjusting bolt 3 is sequenti...

Embodiment 2

[0038] (Embodiment 2, wiring assembly)

[0039] Figure 5 to Figure 8 A specific embodiment of the wiring assembly in the present invention is shown, wherein Figure 5 It is a schematic diagram of a three-dimensional structure of the wiring assembly in the present invention; Figure 6 yes Figure 5 A schematic diagram of the three-dimensional structure of the wiring assembly shown when viewed from another angle; Figure 7 yes Figure 5 Cross-sectional view of the wiring assembly shown, taken through the middle, Figure 8 yes Figure 5 A three-dimensional structural schematic diagram of the wiring assembly shown in the contactor.

[0040] This embodiment is a wiring assembly using the anti-off terminal in Embodiment 1, see Figure 5 to Figure 7 , compared with Embodiment 1, it also includes an insulating terminal block 4, and the terminal block is provided with at least one accommodating cavity 41 for setting an anti-off terminal; the top wall of the accommodating cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com