Pneumatic radial tire and process for producing retreaded tire

A technology for radial tires and treads, applied to tire treads/tread patterns, tire parts, tires, etc., can solve problems such as long time and different time required, and achieve improved productivity, good productivity, and restraint Effect of Oxidation Deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

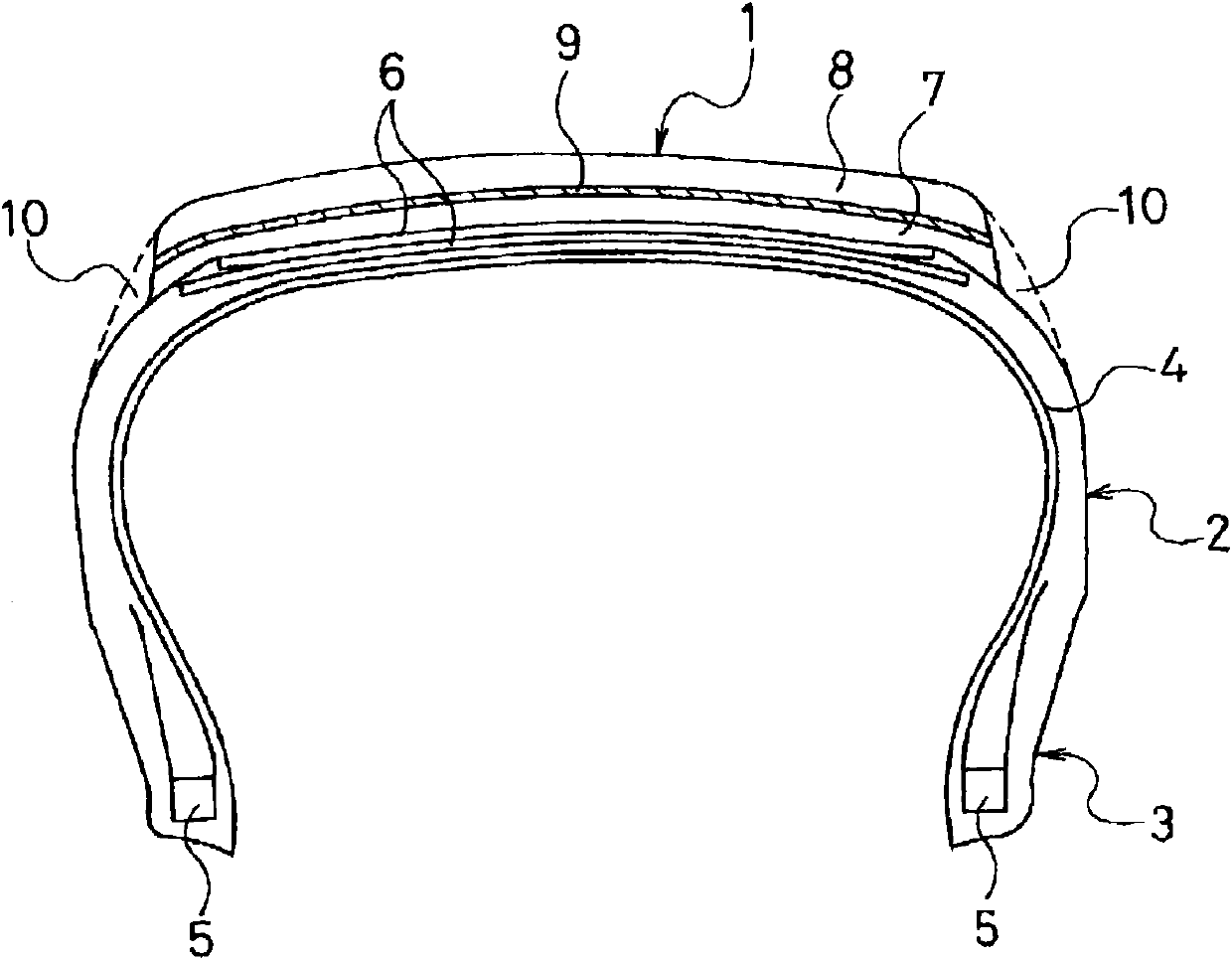

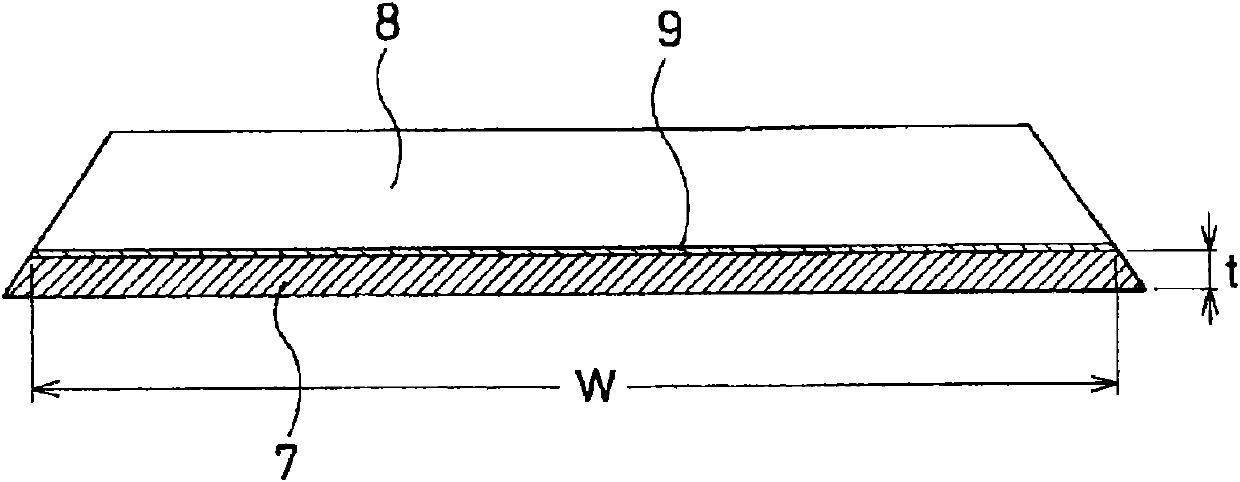

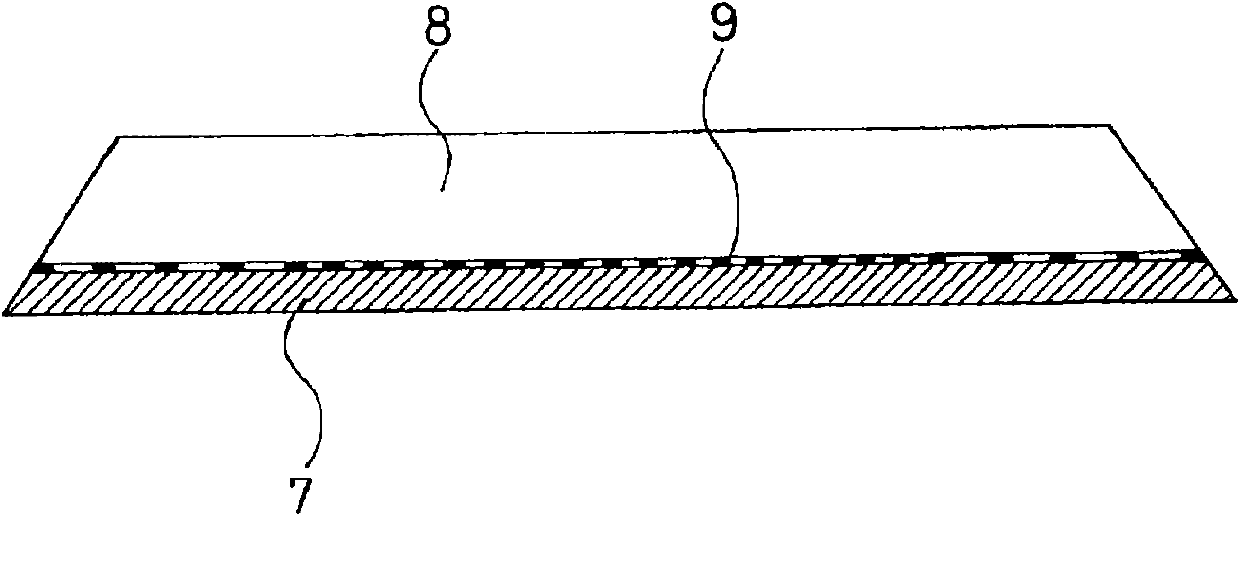

[0051] In the retreading process of waste pneumatic radial tires with a tire size of 11R22.5, a gauge under the tread groove of 5mm, and a residual groove of 3mm after wear, the position 3mm above the belt layer will be made of nylon 6 A thermoplastic film layer 9 (thickness: 100 μm) formed of a thermoplastic elastomer composition of / 66 and Br-IPMS is arranged between the rubber layer 7 on the belt side with a thickness of 3 mm and the rubber layer 8 on the cap side with a thickness of 4.5 mm tire (Example 1), and a conventional tire without a thermoplastic film layer 9 (Conventional Example).

[0052] In addition, the thermoplastic film layer 9 is adjacently bonded to an adhesive rubber layer (thickness: about 400 μm) on the outer peripheral side.

[0053] The above two types of tires were subjected to the retreading process by the following methods, respectively.

[0054] For the tires of the examples, the surface of the tread was heated to 160° C., and the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com