Backflow type anti-overflow boiler

An anti-overflow and backflow hole technology, applied in the direction of anti-overflow, etc., can solve the problems of gas extinguishment, stove pollution, unsatisfactory effect, etc., and achieve the effect of simple structure and ideal use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

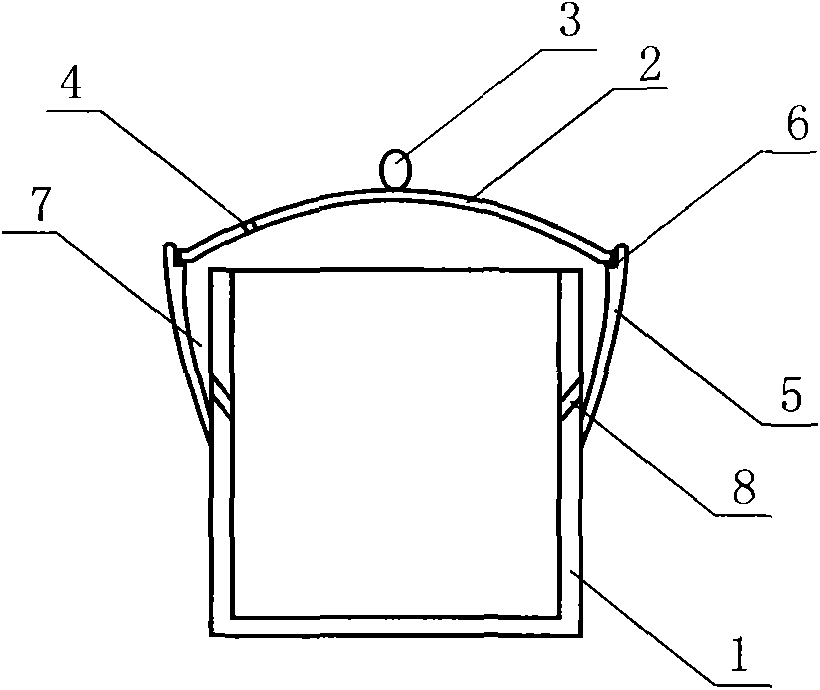

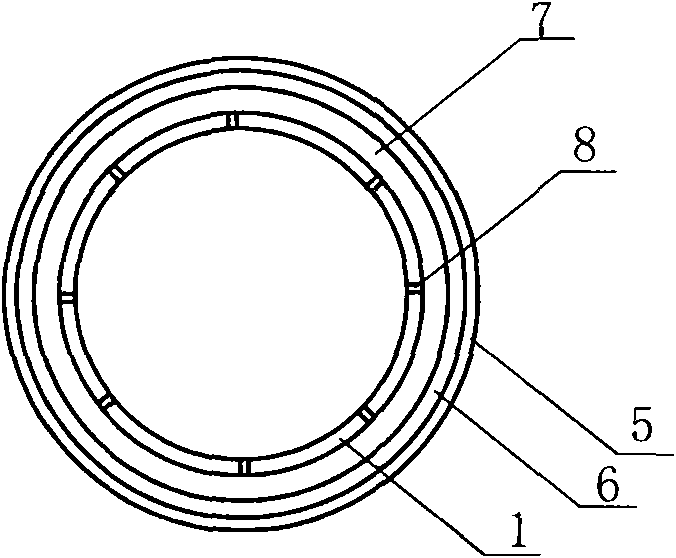

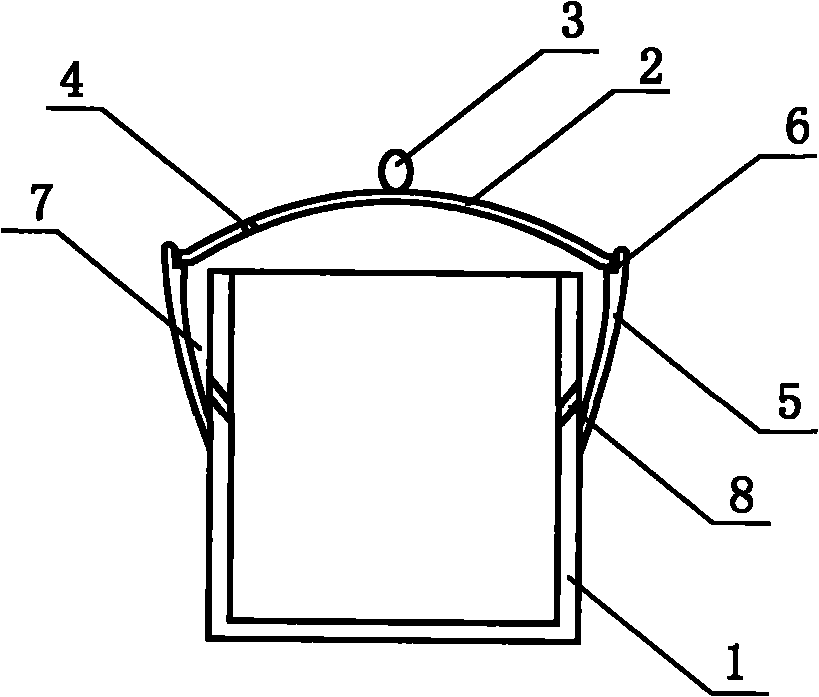

[0012] As can be seen from the accompanying drawings, the present invention includes a pot body 1 and a pot cover 2. The pot body 1 is provided with a jacket 5 and forms a cavity 7 with the pot body 1. The pot body 1 at the bottom of the cavity 7 is provided with several pots. The backflow hole 8 connected with the cavity 7 in the body, the upper end of the jacket 5 is higher than the mouth of the pot body and is provided with an overflow table 6, and a pot cover 2 is provided in cooperation with the overflow table 6, and a vent hole is provided on the pot cover 2 4 and handle 3.

[0013] It should be noted that the content disclosed in the present invention is only the best mode for the application of the present invention, which is not disclosed in the present invention, and is closely related to the replacement of conventional means in the technical field, and all belong to the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com