Sealing device of vertical pump

A sealing device, vertical pump technology, applied in non-variable-capacity pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of high maintenance cost, failure, lack of lubrication on the sealing surface, etc. Improve work efficiency, long service life and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

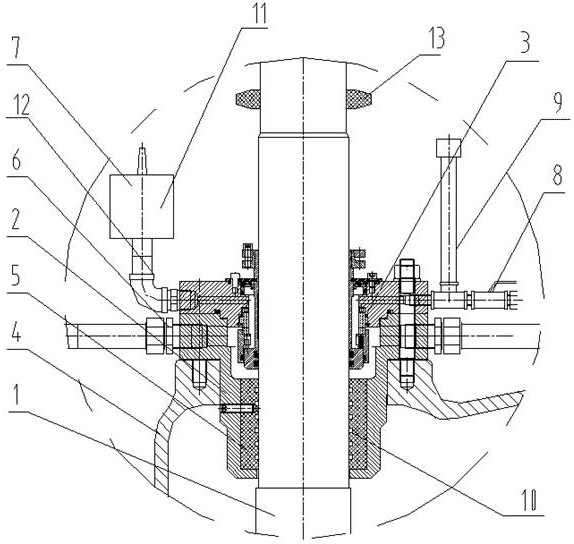

[0012] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

[0013] in the attached figure 1 Middle: A sealing device for a vertical pump, including a pump shaft 1, a sealing box 2 is arranged on the pump shaft 1, a mechanical seal 3 is arranged on the upper end of the sealing box 2, and the lower part of the sealing box 2 is connected to the discharge section of the pump. 4; the inside of the sealed box 2 is provided with a sliding bearing 5, and the sliding bearing 5 is sleeved on the pump shaft 1; the inner surface of the sliding bearing 5 is provided with several decompression grooves 10; due to the inner hole of the sliding bearing and the The pump shaft has a small radial clearance and a fluid decompression groove, which play a role in reducing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com