Clamping tool for grinding end surface of gland sealing ring of steam turbine

A technology for clamping tools and steam seal rings, which is used in manufacturing tools, grinding workpiece supports, machine tools suitable for grinding workpiece planes, etc. and other problems, to achieve the effect of convenient and fast clamping, reducing time consumption and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

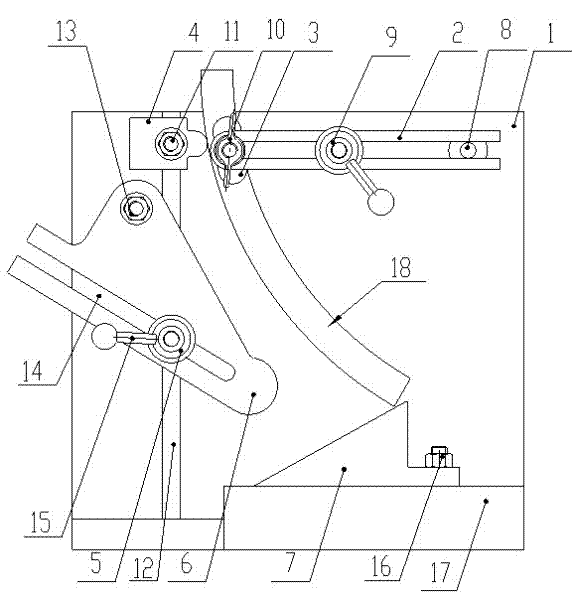

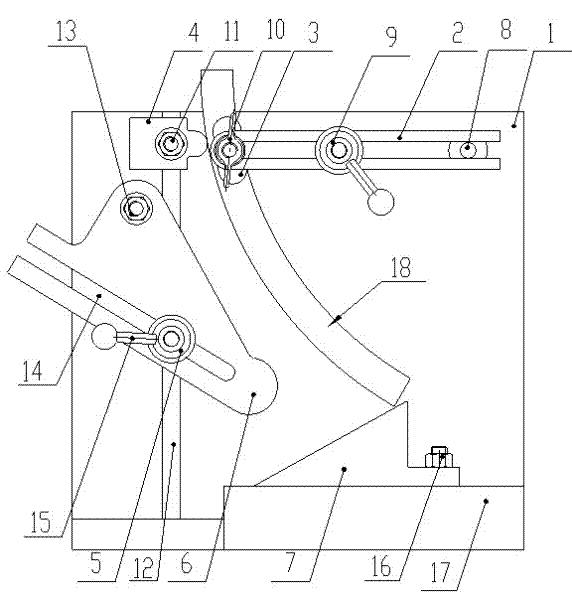

[0017] figure 1 Among them, a clamping tool for grinding the end face of steam turbine steam seal ring, including a curved plate 1, a U-shaped pressure plate 2 is horizontally fixed on one side of the curved plate 1 plane by a rotating handle I9, and the lower part of the closed end of the U-shaped pressure plate 2 passes through The wing screw 10 is fixed with a pressure head 3; the closed end of the U-shaped pressure plate 2 on the bent plate 1 is provided with a guide groove 12 perpendicular to the U-shaped pressure plate 2, and the guide groove 12 is provided with a support block 4 and a rotating support from top to bottom. Block 6; a slanted block 7 is provided on the side of the curved plate 1 opposite to the U-shaped curved plate 2 on the plane.

[0018] The open end of U-shaped pressing plate 2 is stuck on the positioning post 8 on the bent pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com