Housing, production method therefor and electronic device

A manufacturing method and housing technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, etc., can solve problems such as inability to properly polish and coat the surface, poor yield, and inability to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0036] The first embodiment is a method of manufacturing an electronic device case formed by integrally molding a self-healing surface-processed film and a resin.

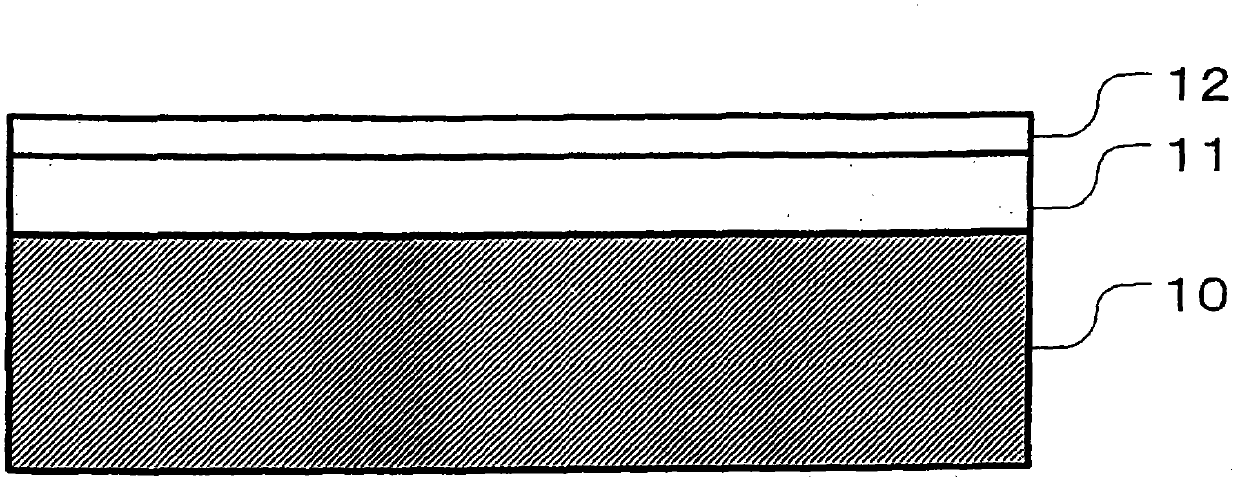

[0037] figure 1 It is a partial cross-sectional view of an electronic device case manufactured by the manufacturing method of the first embodiment. refer to figure 1 , The electronic device casing manufactured by the manufacturing method of the first embodiment has a main body resin 10 , a film base layer 11 , and a self-healing layer 12 .

[0038] The main body resin 10 is a resin component that constitutes the shape of the electronic device housing, and is made of PLA (polylactic acid, polylactic acid), ABS (Acrylonitrile Butadiene Styrene, acrylonitrile-butadiene-styrene copolymer), PC (polycarbonate, poly Carbonate), PC / ABS alloy (alloy) and other resins.

[0039] The film base layer 11 is integrally molded with the main body resin 10 in a state where a predetermined decorative layer is attached. The film b...

no. 2 Embodiment approach

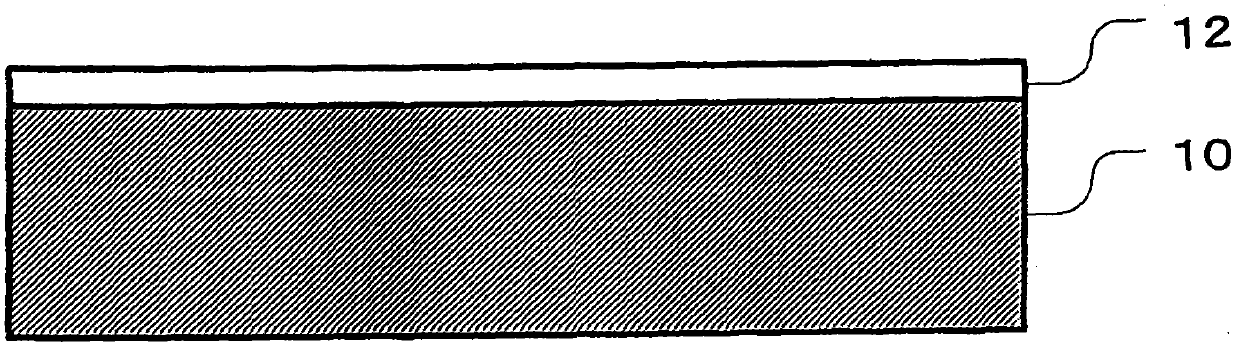

[0048] image 3 It is a partial cross-sectional view of an electronic device case manufactured by the manufacturing method of the second embodiment. refer to image 3 , The electronic device casing manufactured by the manufacturing method of the second embodiment has a main body resin 10 and a self-healing layer 12 . The main body resin 10 and the self-healing layer 12 are made of the same materials as the main body resin 10 and the self-healing layer 12 constituting the case of the electronic device manufactured by the manufacturing method of the first embodiment.

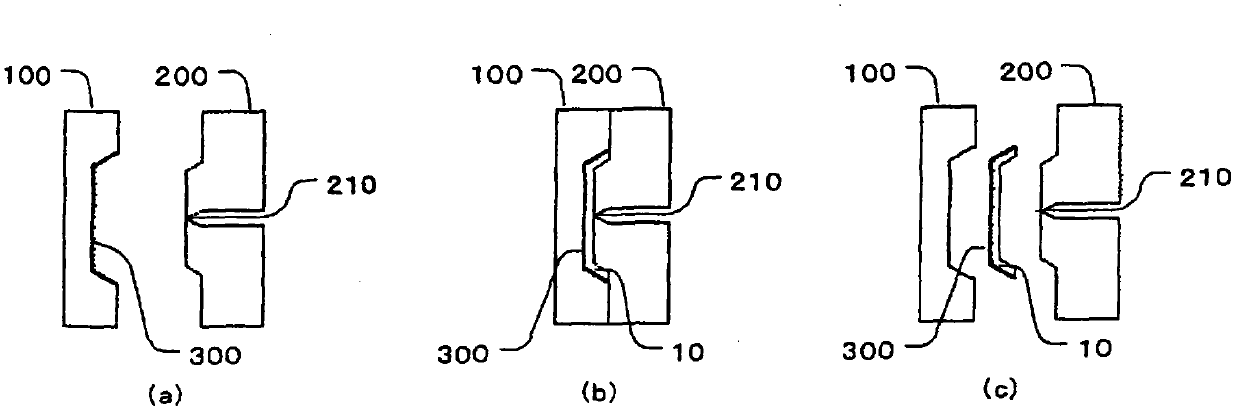

[0049] Figure 4 It is a figure explaining the manufacturing method of 2nd Embodiment. refer to Figure 4 , the electronic device housing manufactured by the manufacturing method of the second embodiment, due to the figure 2 The production method of the first embodiment described in hereinafter is also produced by injection molding, so the description will focus on the differences.

[0050] First, if Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com