Weather strip

一种密封条、密实的技术,应用在密封装置、发动机的密封、发动机元件等方向,能够解决降低密封性能、密封条210塌陷、易在彼此离开的方向上变形等问题,达到凸缘拔出力大、反转量增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

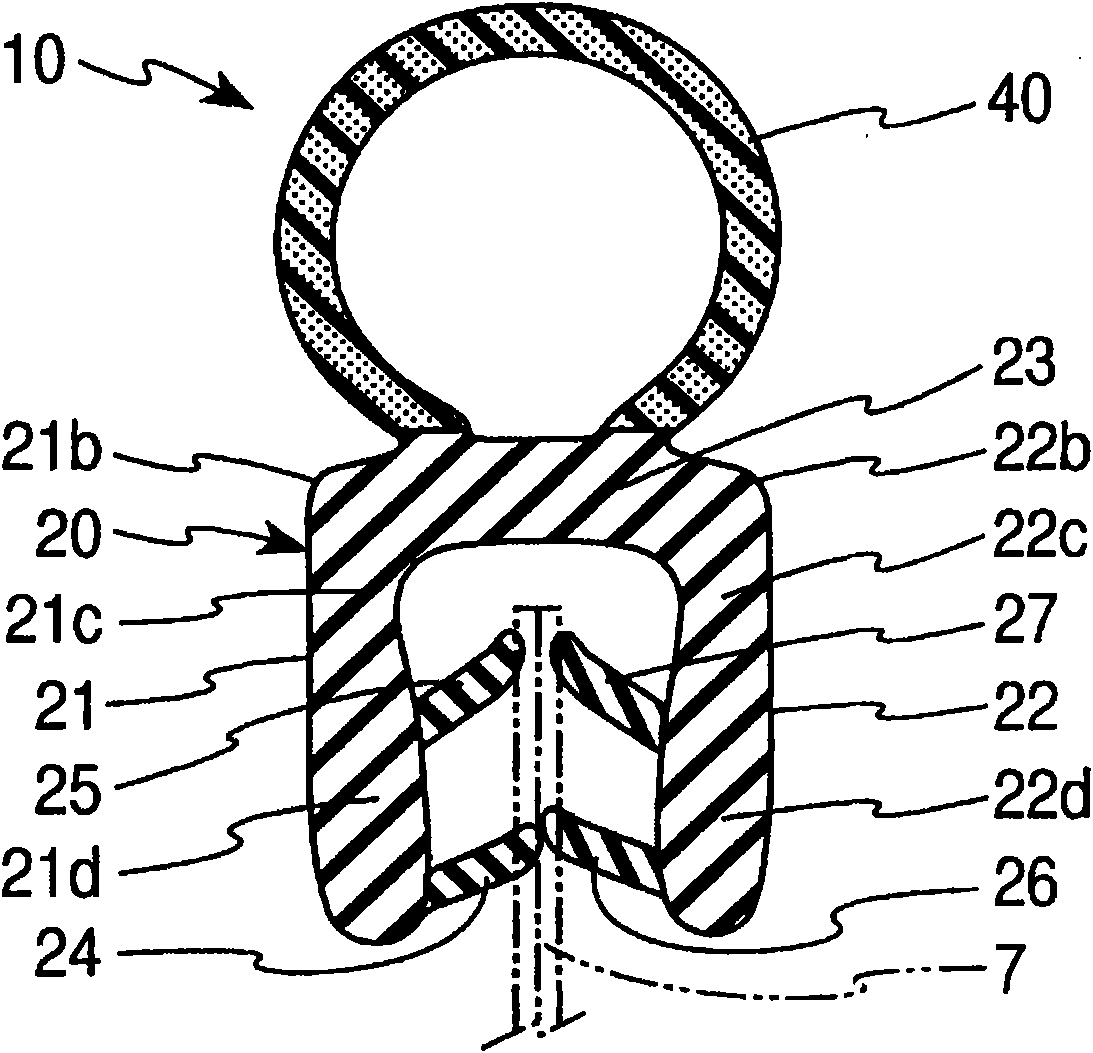

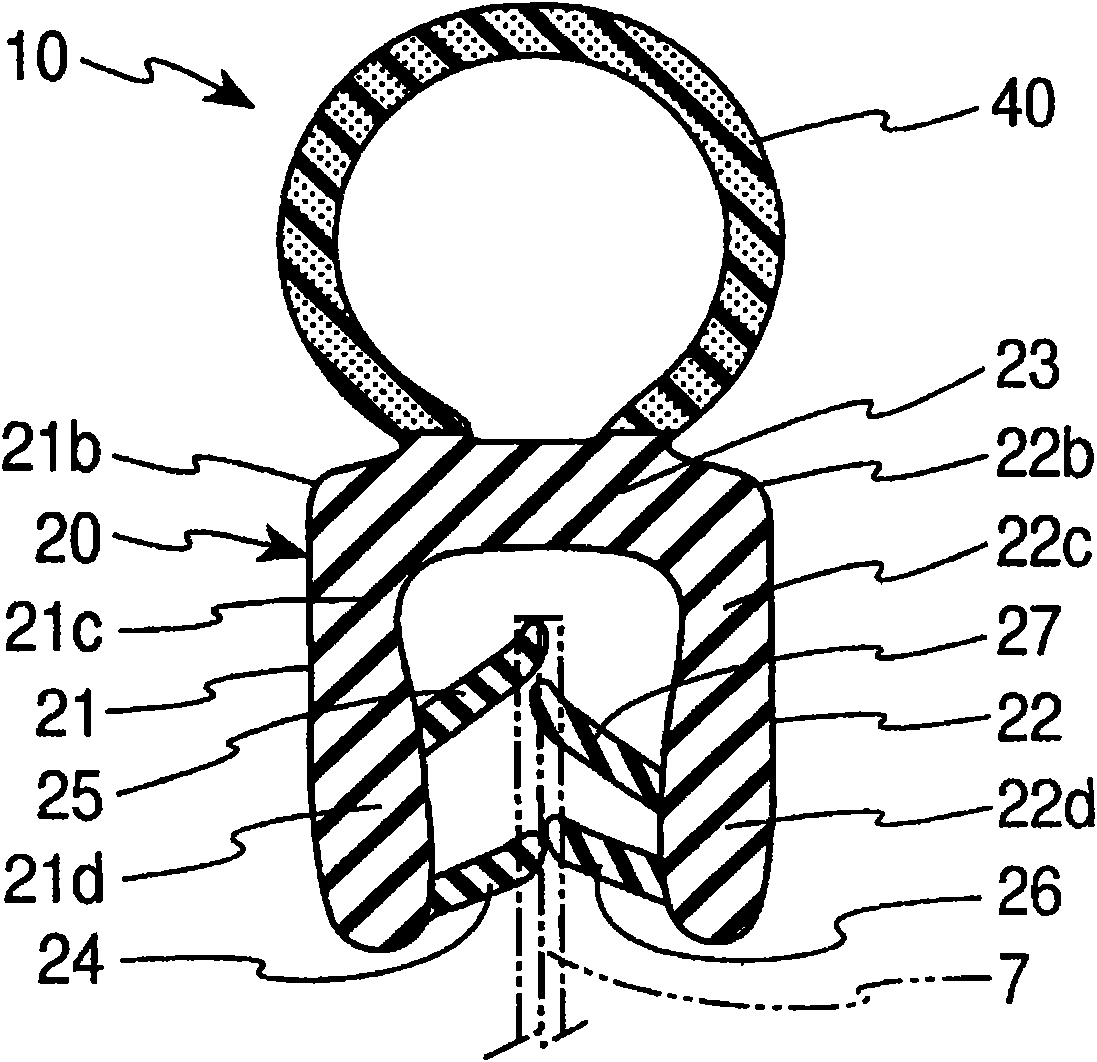

[0040] Refer below Figure 1 to Figure 3 Examples of the present invention will be described.

[0041] figure 1 It is a sectional view of the sealing strip 10 according to the first embodiment of the present invention. Similarly, figure 2 It is a sectional view of the sealing strip according to the second embodiment of the present invention.

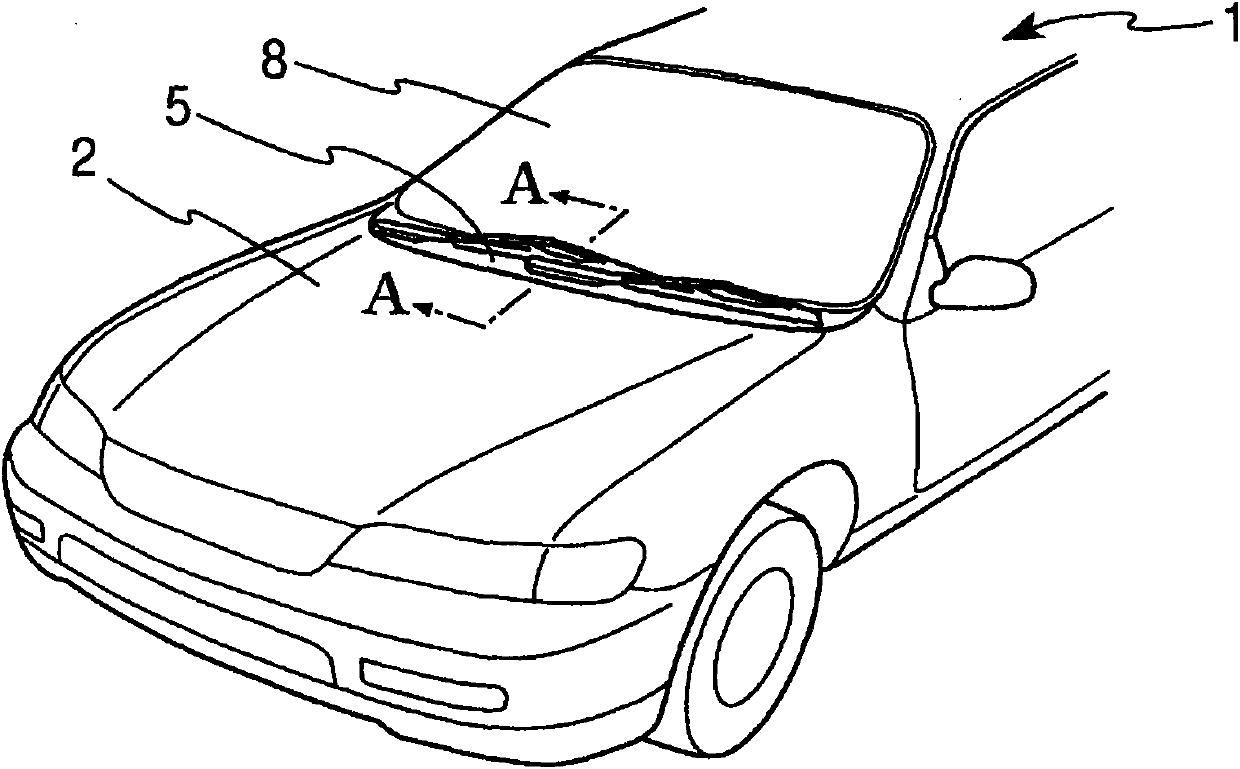

[0042] The first embodiment of the present invention is described as an example in which the weather strip 10 is used in a cowl vent hole provided in a line on one side on the rear side of the periphery of the nacelle. The present invention can be widely used as a weather strip for sealing openings of motor vehicles, such as door openings, roof openings, rear trunks and rear door weather strips of motor vehicles.

[0043] Such as figure 1 As shown, the weather strip 10 of the first embodiment of the present invention is composed of a fastening part 20 and a hollow sealing part 40 , the fastening part 20 is installed on the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com