Electric power steering assistance control method

A technology of electric power steering and control method, which is applied in the direction of automatic steering control components, electric steering mechanism, steering mechanism, etc., which can solve the problems that cannot be realized, and achieve the effects of accelerating the return speed, improving the feel and reducing the influence of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

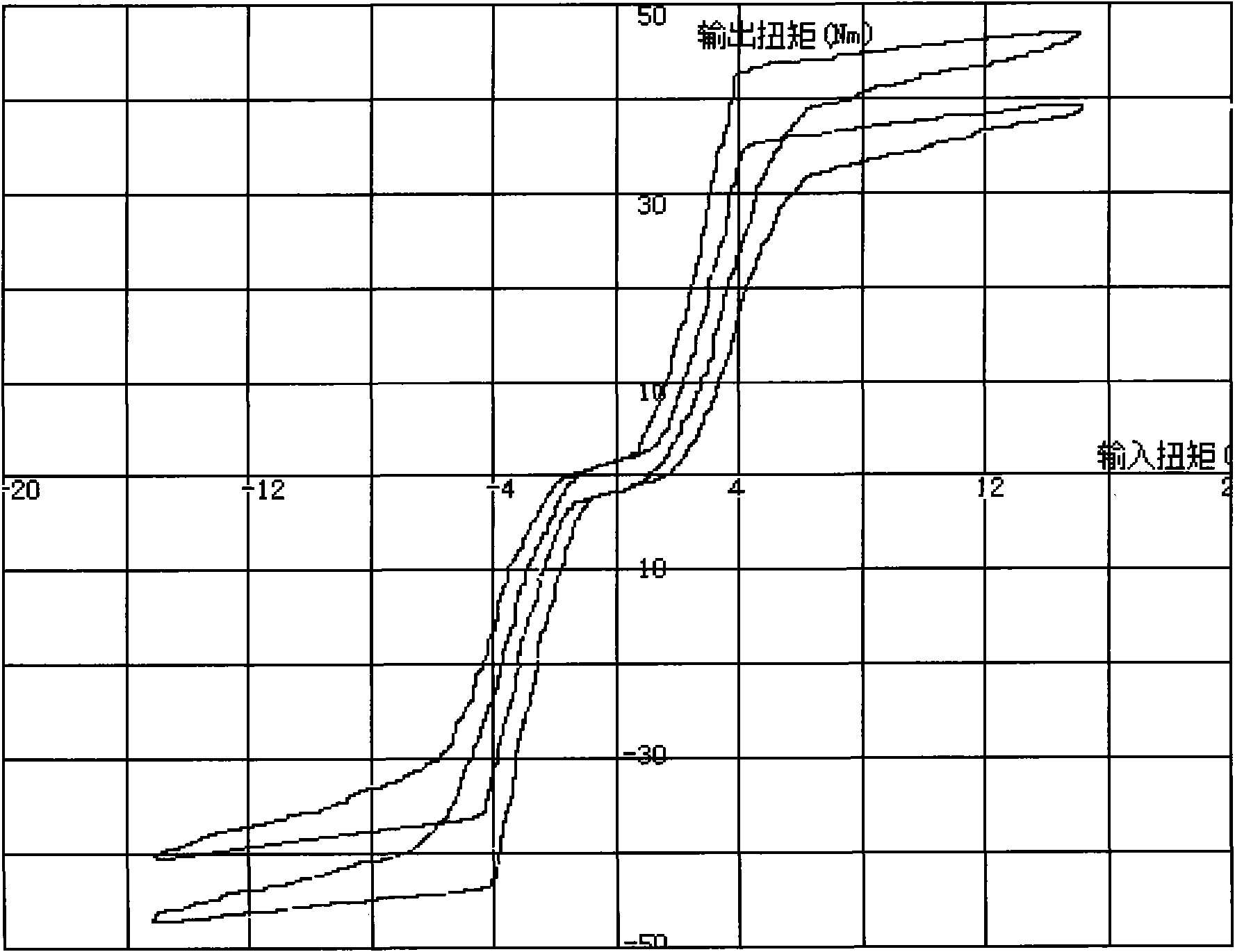

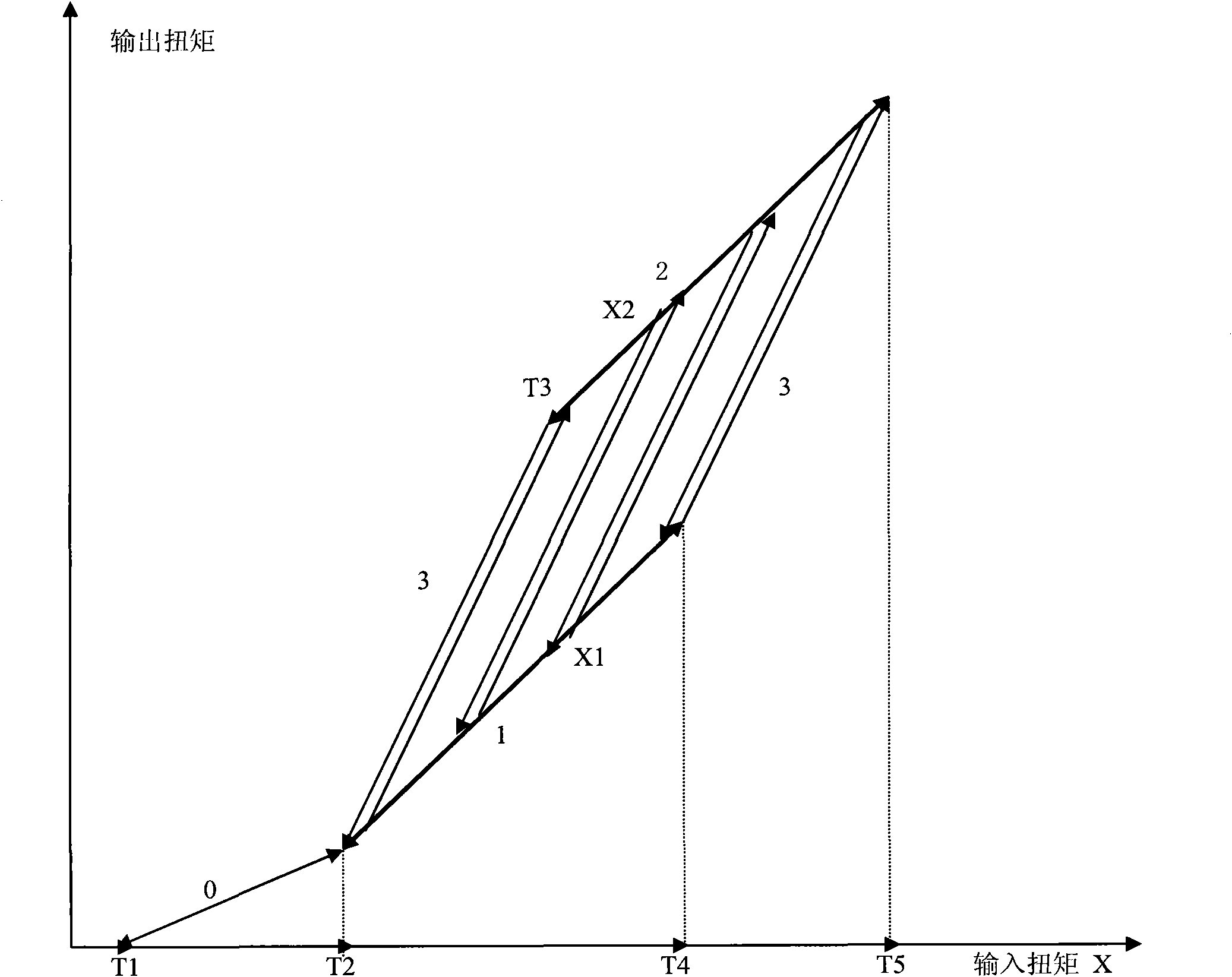

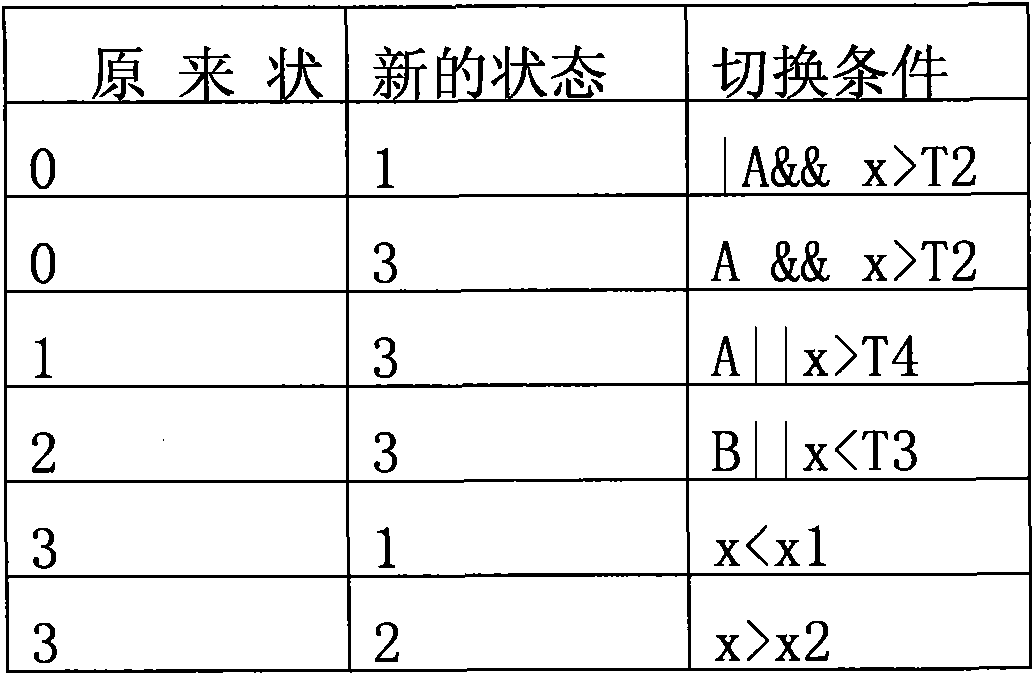

[0014] Such as figure 2 and image 3 As shown in Fig. 1 , an electric power steering assist control method is based on the basic assist curve to calculate the torque change trend according to the historical state and the existing state, and select the assist curve segment according to the operation, so that the control characteristics of the actual controller are biased towards the ideal The shape of the power assist curve is to reduce the influence of friction, speed up the speed of returning to the center, and improve the feel. The zero curve 0 is the power assist curve when the torque is relatively small, and the first curve 1 is the steering and return to the bottom line when the torque variation trend is relatively small. The second curve 2 is the steering and return to normal peak line when the torque variation trend is relatively small, and the third curve 3 is the steering and return to normal acceleration line when the torque variation trend is relatively large. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com