Rear suspension system of automobile longitudinal power assembly

A technology of powertrain and rear suspension, applied in the direction of control device, vehicle components, substructure, etc., can solve the problems of low position of gearbox, adjustment of elastic components, and small space for gearbox cushion, and achieve volume and compression. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

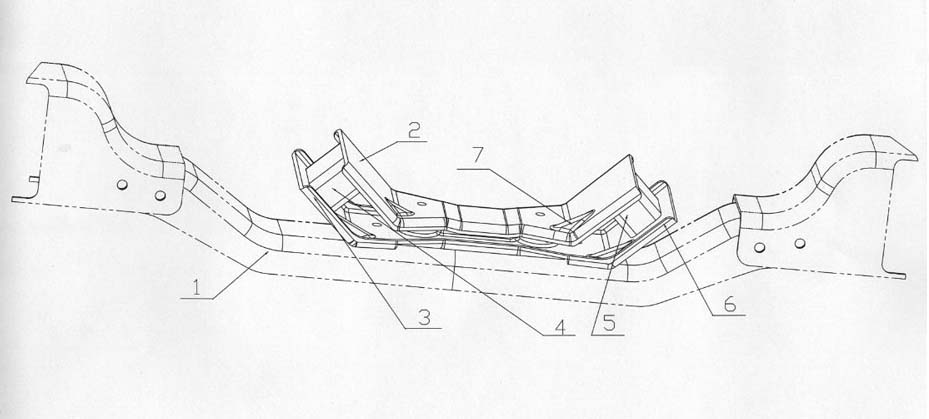

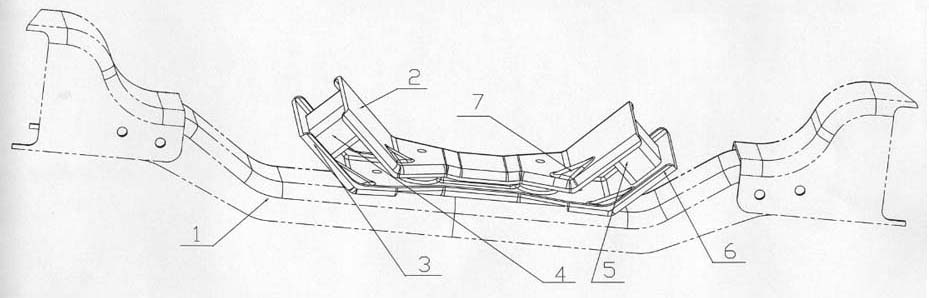

[0012] Such as figure 1 As shown, the rear suspension system of the automobile longitudinal powertrain according to the present invention includes an upper bracket 2, a lower bracket 3 arranged on the gearbox lower beam 1, and a group of elastic elements 4 arranged between them , 5, the upper bracket 2 and the lower bracket 3 extend upwardly from both sides of the gearbox, and the elastic elements 4, 5 are arranged between the upper and lower brackets 2, 3 on both sides of the gearbox; The sides of the lower brackets 2, 3 have flanges 6, and the middle parts of the upper and lower brackets 2, 3 are provided with reinforcing ribs 7.

[0013] The middle position of the upper surface of the upper bracket 2 is connected to the gearbox body through bolts, and the lower surfaces on both sides are connected to the elastic elements 4 and 5 through bolts or bonding; the upper surfaces on both sides of the lower bracket 3 are connected to the The elastic elements 4 and 5 are connected,...

Embodiment 2

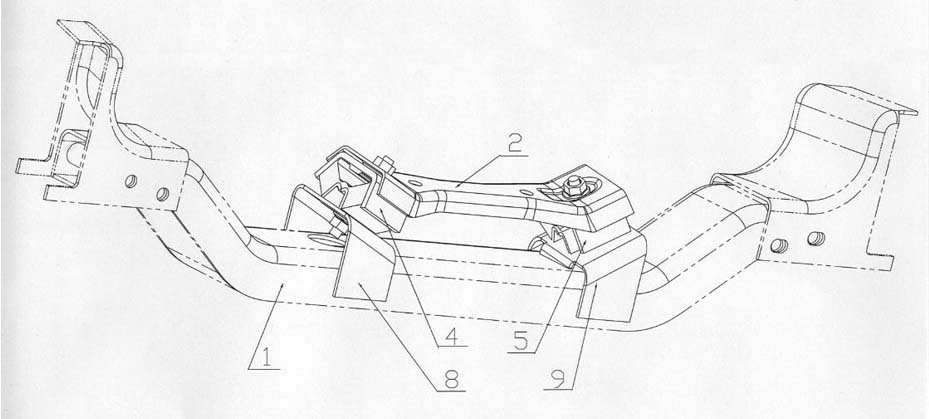

[0015] The rear suspension system of the automobile longitudinal powertrain according to the present invention comprises an upper bracket 2, a lower bracket 3 arranged on the lower beam 1 of the gearbox, and a group of elastic elements 4, 5 arranged between them, In order to make its structure compact, the lower bracket 3 can be simplified as a pair of support slant plates 8, 9 directly welded on the gearbox lower beam 1, as figure 2 As shown, the elastic elements 4, 5 are bolted (or bonded) on the support swash plates 8, 9, and then the lower surfaces on both sides of the upper bracket 2 are connected to the elastic elements 4, 5 by bolts or bonding; The direct welding between the lower beam 1 of the gearbox and the lower bracket (that is, the support slant plates 8, 9) ensures the rigidity of the lower bracket, and at the same time, due to the simplicity of the parts and the flexibility of the design, it is possible to reduce the cost of the suspension system .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com