Saccharification mixer

A technology of mixers and stirring teeth, which is applied in the field of mixing machinery, can solve problems such as difficult process control, high cost, and high labor intensity, and achieve the effects of reducing costs, reducing labor intensity, and eliminating noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

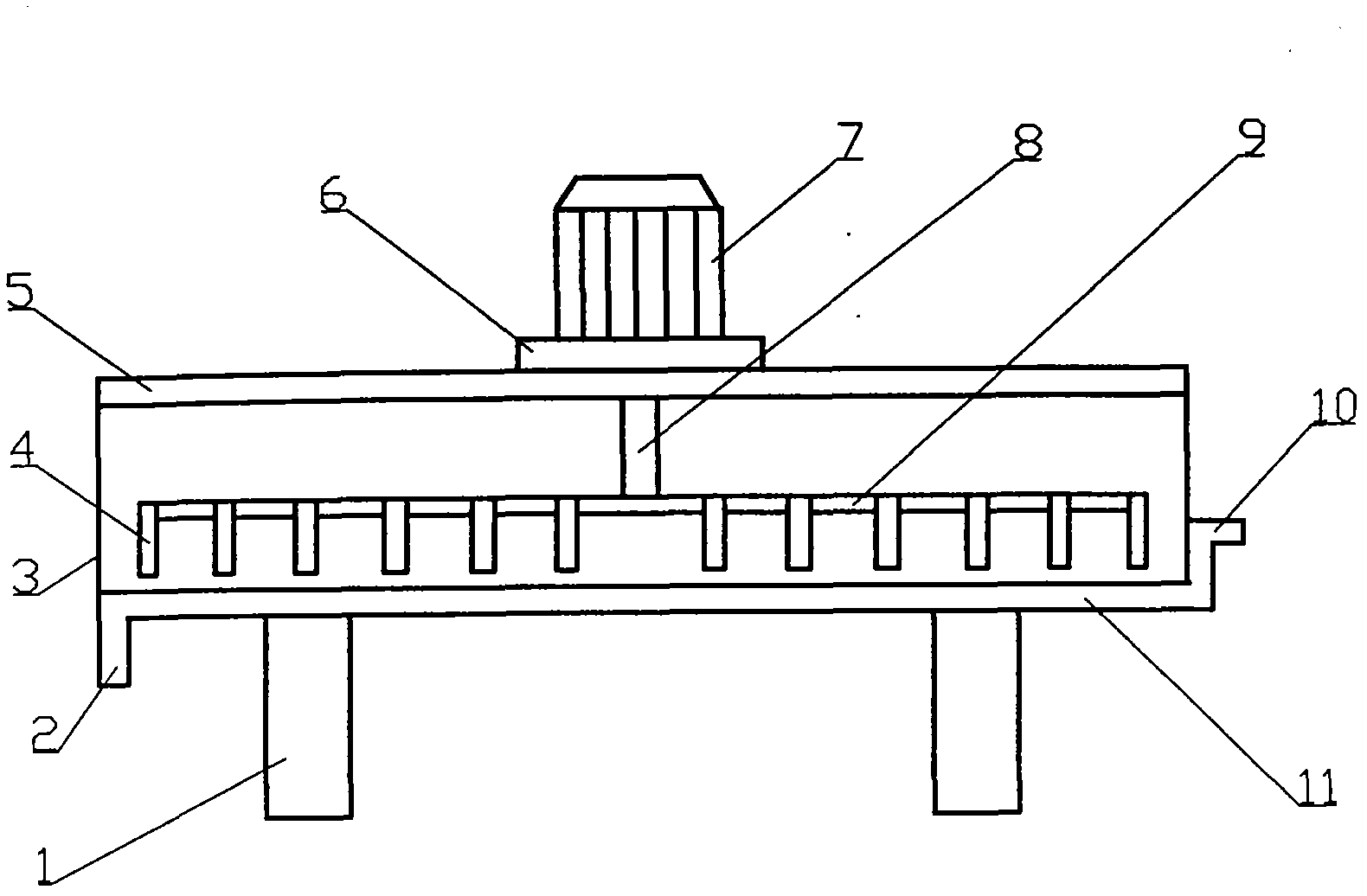

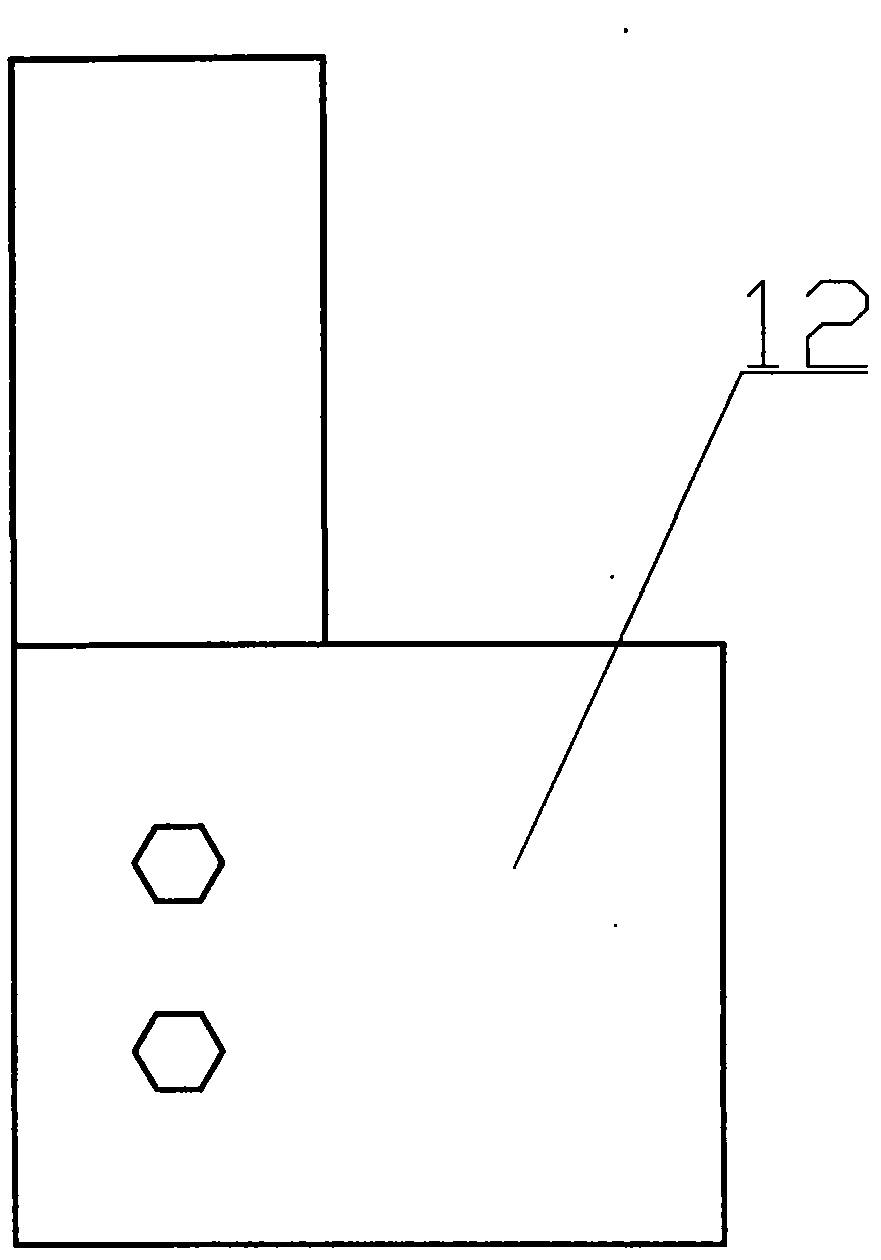

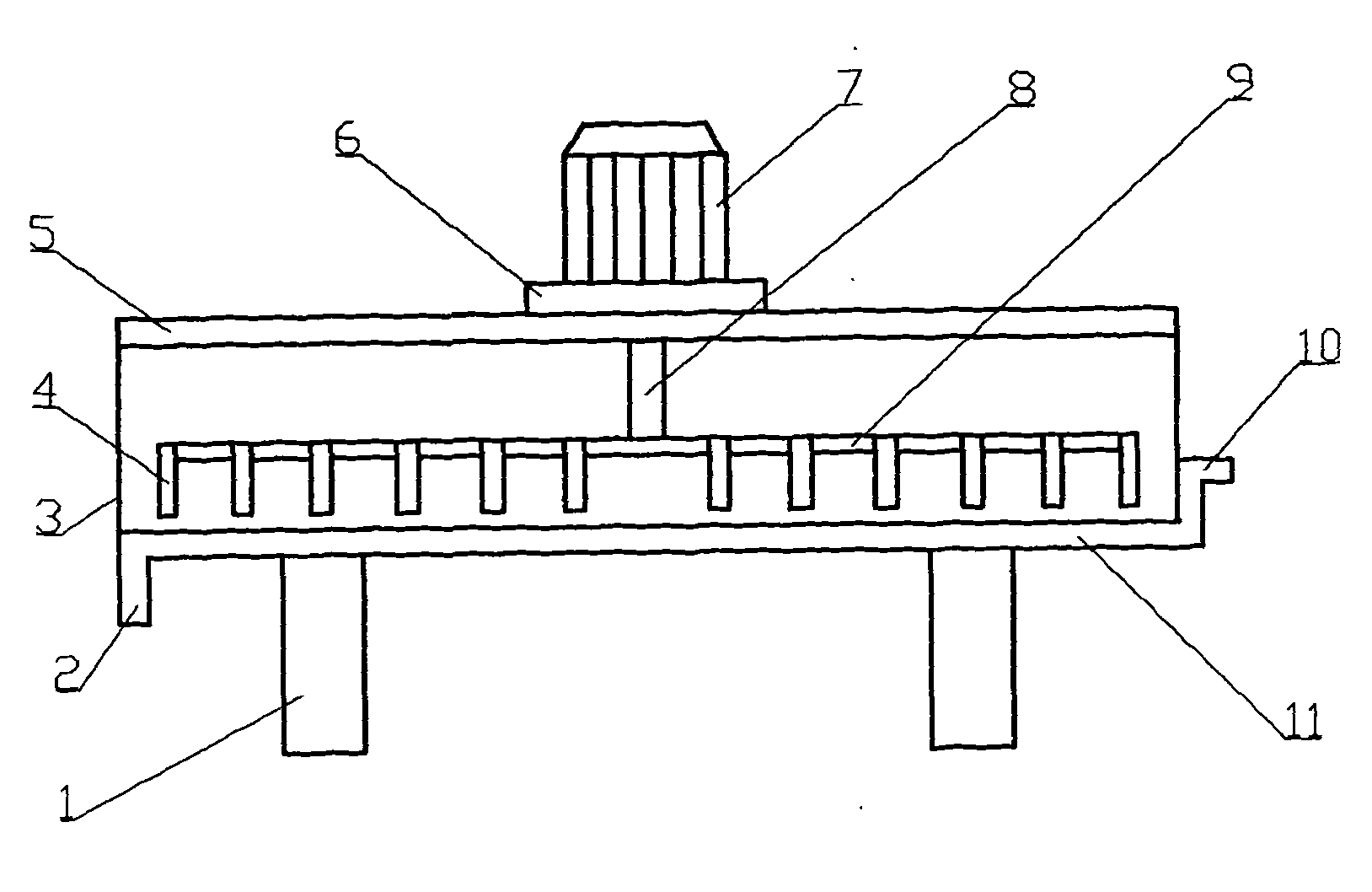

[0011] As shown in the figure, a radial stirring bar 9 is installed in the disc-shaped tank 3, an upper vertical transmission shaft 8 is installed in the middle of the stirring bar 9, and a reduction box 6 is installed on the upper end of the transmission shaft 8. A matching motor 7 is installed above the reduction box 6; a plurality of lower vertical stirring teeth 4 are installed on the lower side of the stirring bar 9, and a tank interlayer 11 is left at the bottom of the tank 3, and the tank interlayer 11 is formed by the water inlet 2 It is communicated with the water outlet 10 and the water pipeline. The reduction box 6 is supported by the reduction box bracket 5. The bottom surface of the tank pond 3 is equipped with a support leg frame 1, and the lower section of the stirring tooth 4 is shovel-like.

[0012] When in use, the glucoamylase materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com