Weft insertion device of air-jet loom

A technology of air jet loom and weft insertion device, which is applied in looms, textiles, textiles and paper making, etc., can solve the problems of difficulty in ensuring the stability of weft insertion and the decrease of flying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

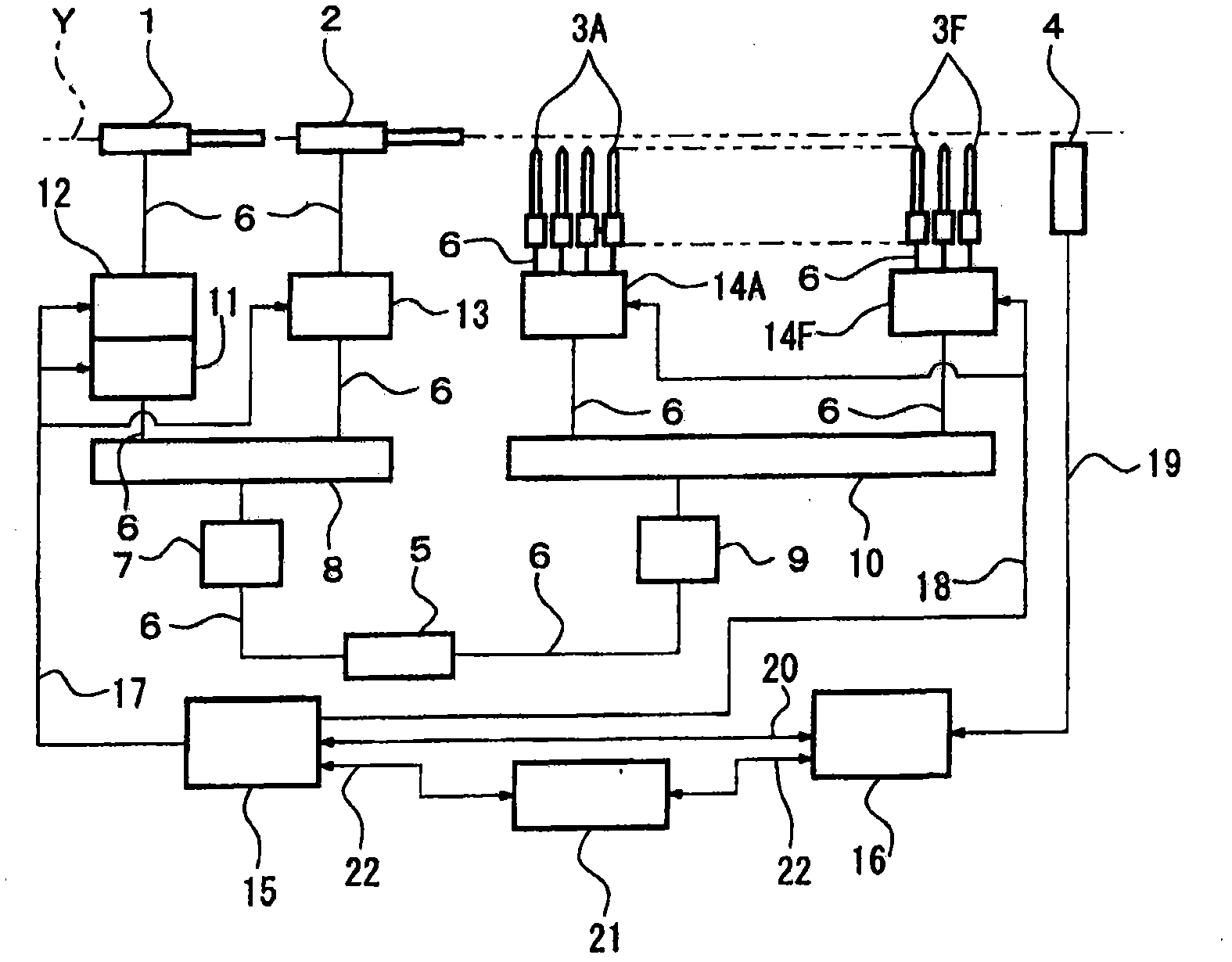

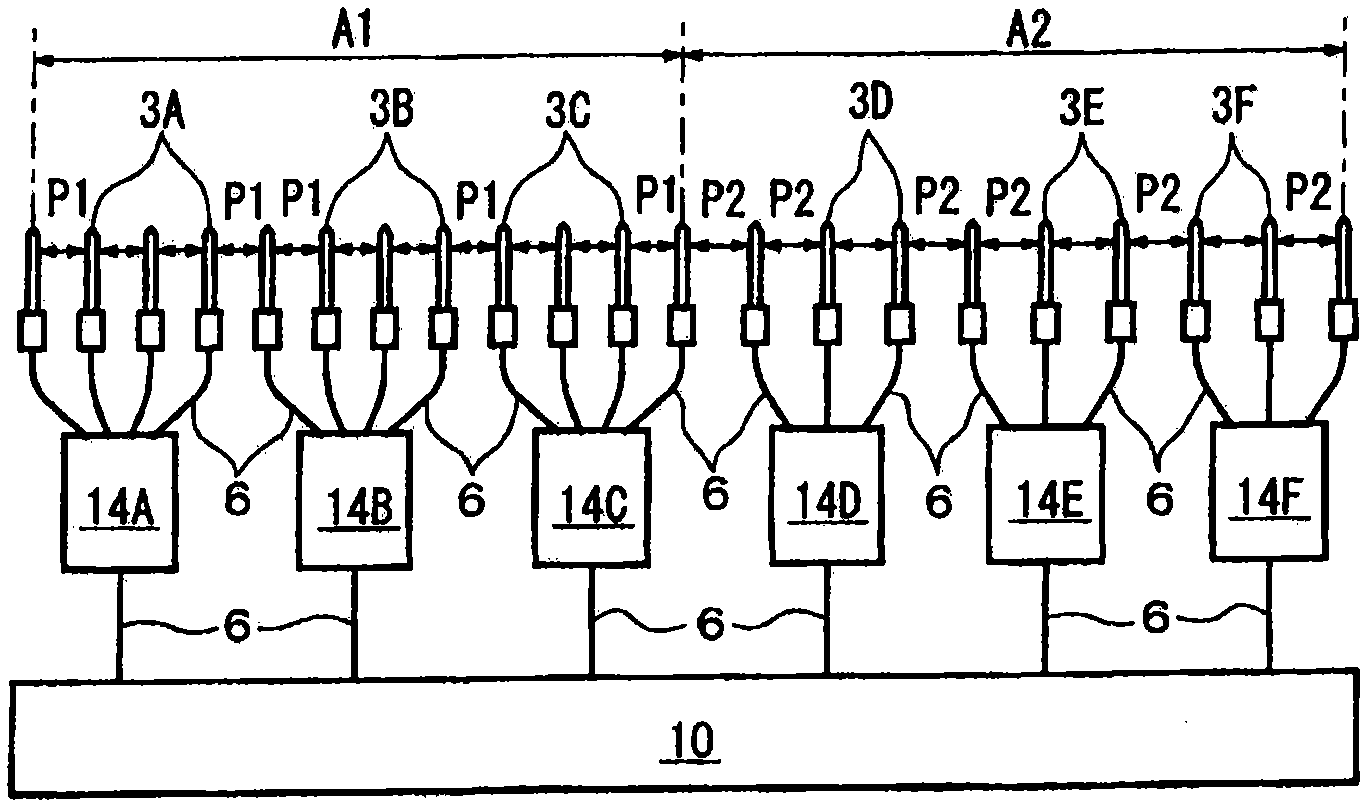

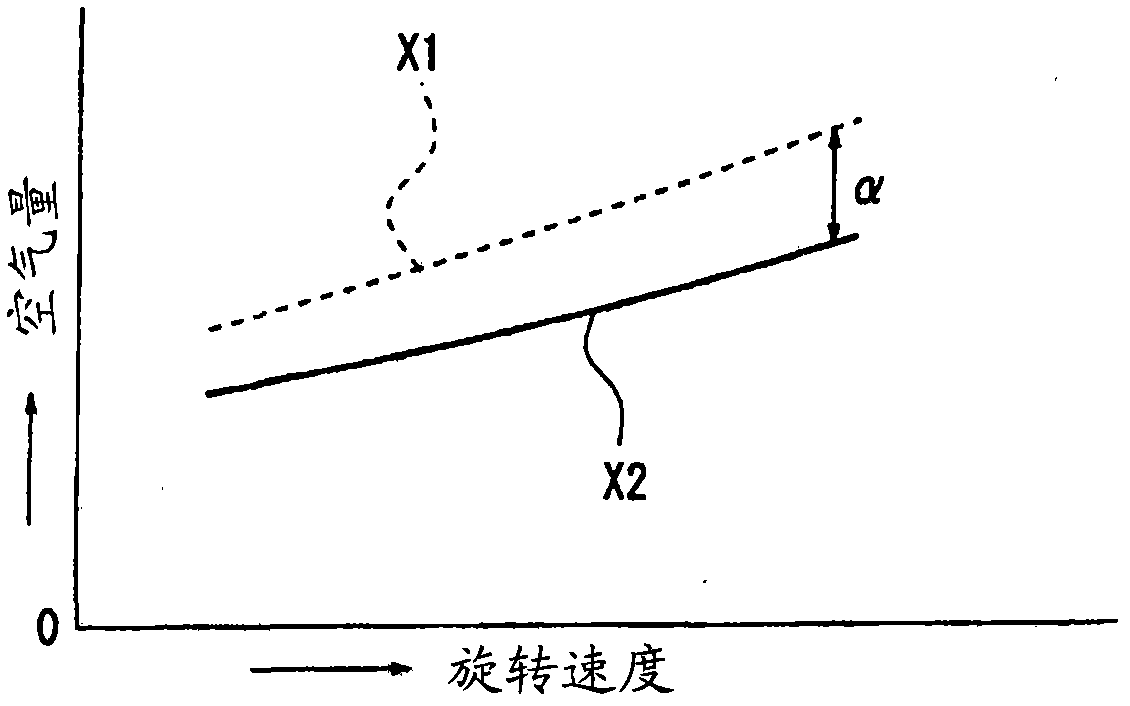

[0014] The following will refer to Figure 1 to Figure 3 A first embodiment will be described. refer to figure 1 The weft yarn Y passed through the weft yarn feeder (not shown) and the weft yarn length measuring device (not shown) is pulled by the tandem nozzle 1, and then inserted by the main nozzle 2 into the weft yarn passage in the warp yarn (not shown) shed. Then, the weft yarn Y inserted by the main nozzle 2 is assisted in flight by air jets emitted from a plurality of auxiliary nozzles 3A to 3F (only 3A and 3F are shown in the figure) arranged at intervals along the weft yarn path. The insertion of the weft yarn Y ends when the weft yarn reaches a predetermined position beyond the end of the fabric positioned relative to the other end of the fabric adjacent to the main nozzle 2 . The weft yarn detector 4 detects the leading end of the continuously inserted weft yarn Y.

[0015] The air supply part 5 is connected to the main tank 8 and the auxiliary tank 10 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com