Quake-proof joint of buried pipe network

A technology of buried pipe and right connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

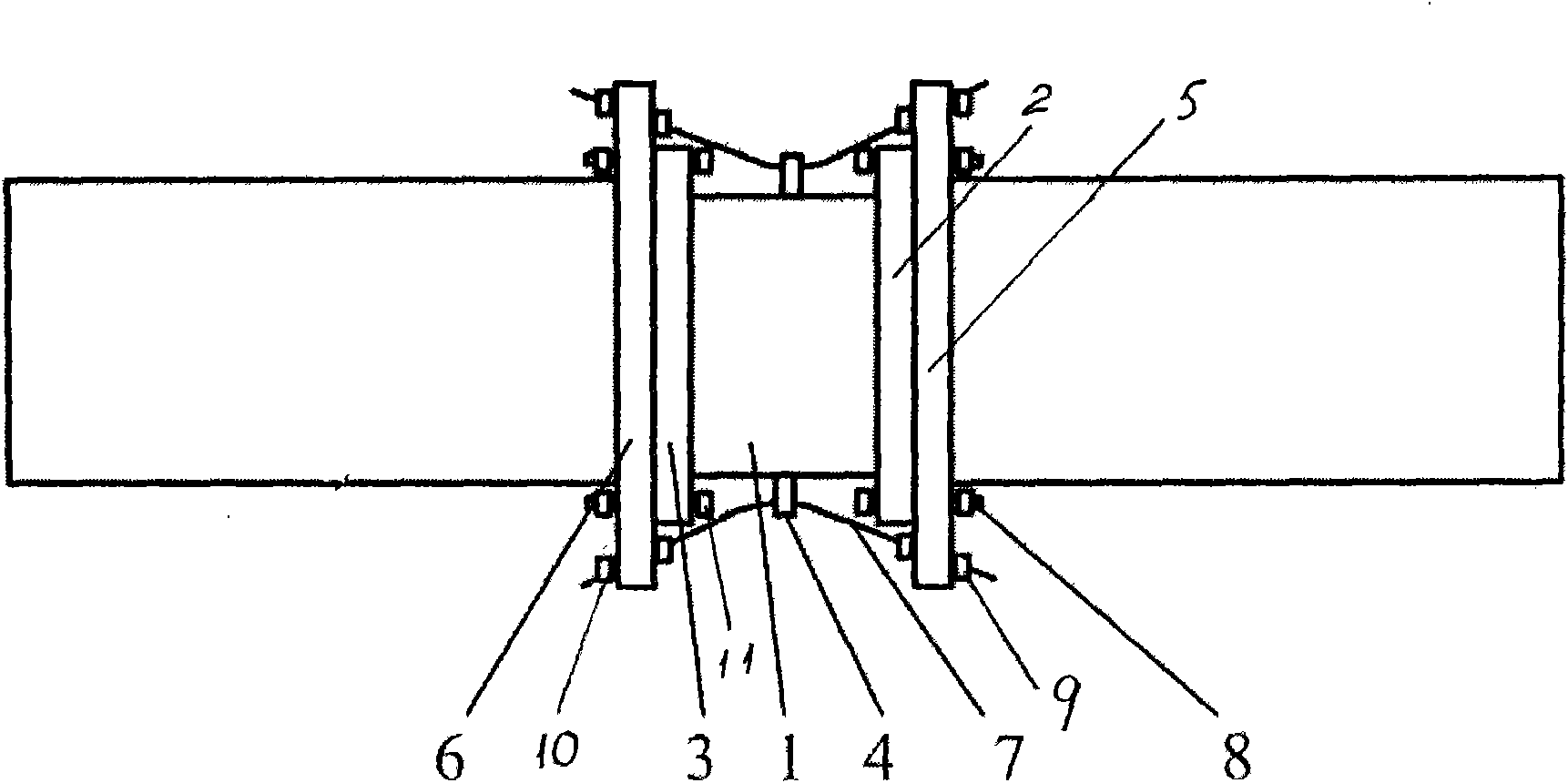

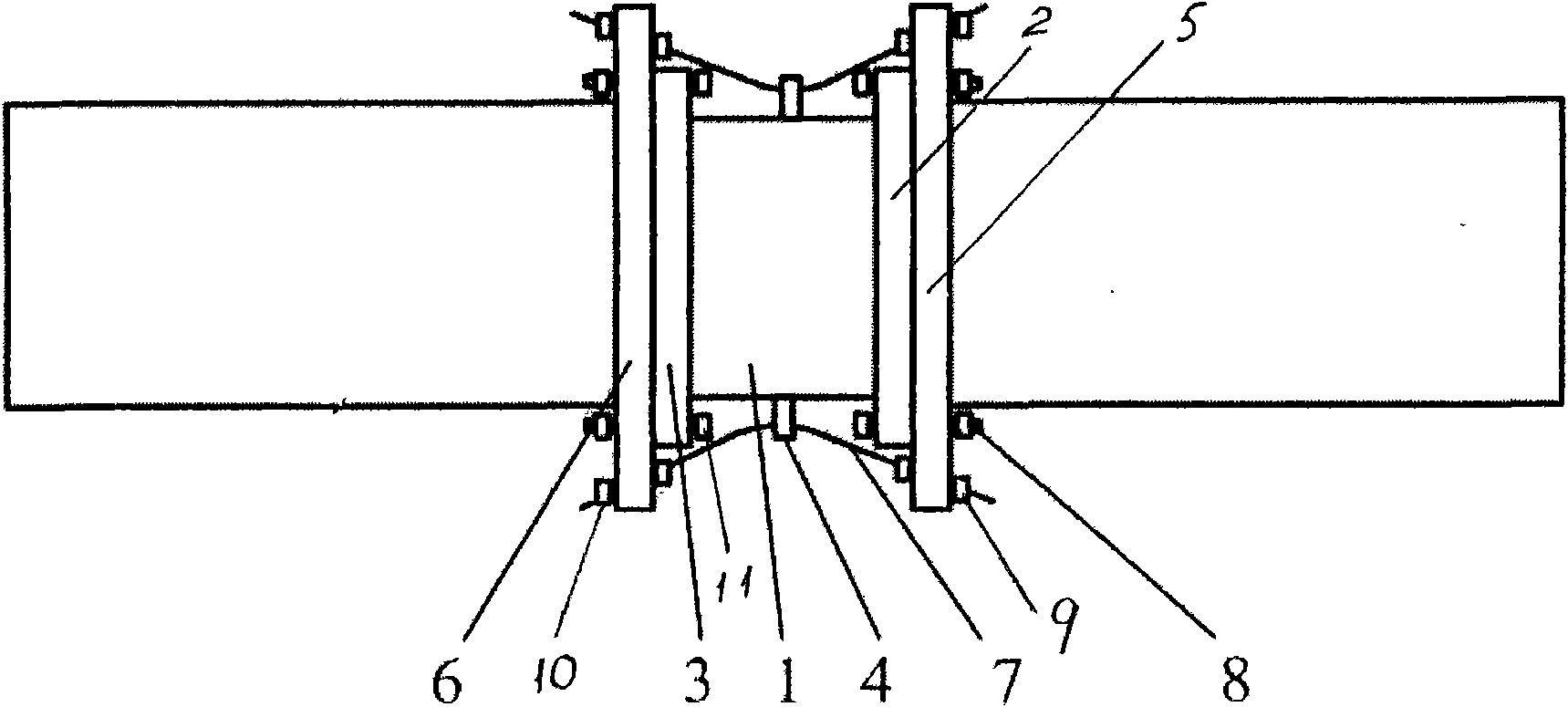

[0010] Example 1: Combining figure 1 , the present invention is a buried pipe network anti-seismic joint, which is composed of connecting pipe (1), right connecting pipe flange (2), left connecting pipe flange (3), collar (4), right pipe flange ( 5), left pipe flange (6), shape memory alloy rod (7), right shape memory alloy bolt (8), right bolt (9), left bolt (10) and left shape memory alloy bolt (11) , the connecting pipe (1) is respectively connected to the right connecting pipe flange (2) and the left connecting pipe flange (3), the collar (4) is located in the middle of the pipe (1), and the left connecting pipe flange (3) passes through the left shape memory The alloy bolt (11) is connected to the left pipe flange (6), the right pipe flange (2) is connected to the right pipe flange (5) through the right shape memory alloy bolt (8), and the right pipe flange (5) is connected to the right bolt (9), the right bolt (9) is connected to the shape memory alloy rod (7), and the ...

Embodiment 2

[0011] Example 2: Combining figure 1 , The invention provides a buried pipe network anti-seismic joint device which increases the anti-seismic capacity of buried pipeline connections, thereby protecting the pipelines from being damaged under earthquake action. A section of connecting pipe is added in the middle of the longer pipes at both ends, and there are two flanges on the connecting pipe for connection with the longer pipes at both ends. There are two sections of sleeves on both sides of the flange respectively, the outer diameter of which is slightly smaller than the inner diameter of the pipe connected to it, and three rubber rings are embedded on it. The flanges of the pipes at both ends are connected by shape memory alloy rods, so as to achieve the ability to recover from deformation. The connecting bolts of the flanges of the connecting pipes are made of shape memory alloy to ensure that a relatively large relative deformation can occur between the two, and at the s...

Embodiment 3

[0013] Example 3: Binding figure 1 , the implementation process of the buried pipe network anti-seismic joint of the present invention is as follows:

[0014] 1. Connecting pipeline structure. Add a section of connecting pipe in the middle of the pipe network, and there are two flanges on the connecting pipe, which are respectively used to connect with the pipes at both ends. There are two sections of casing on both sides of the flange, the outer diameter of which is slightly smaller than the inner diameter of the longer pipe connected to it, and three rubber rings are embedded on it, and the outer diameter of the rubber ring is slightly larger than the longer pipe connected to it. The inner diameter of the long pipe. When the casing and the longer pipe are nested, the rubber ring is squeezed to ensure that the transported material in the pipe does not leak. However, when the casing and the connected long pipe undergo relative displacement, that is, when the two are separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com