Force feedback type underwater cable guider

An underwater cable and force feedback technology, which is applied in the direction of cable laying equipment and electrical components, can solve the problems of cable laying quality influence, low precision of tension force control, and slow response speed, so as to avoid cable dragging and reliable performance , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

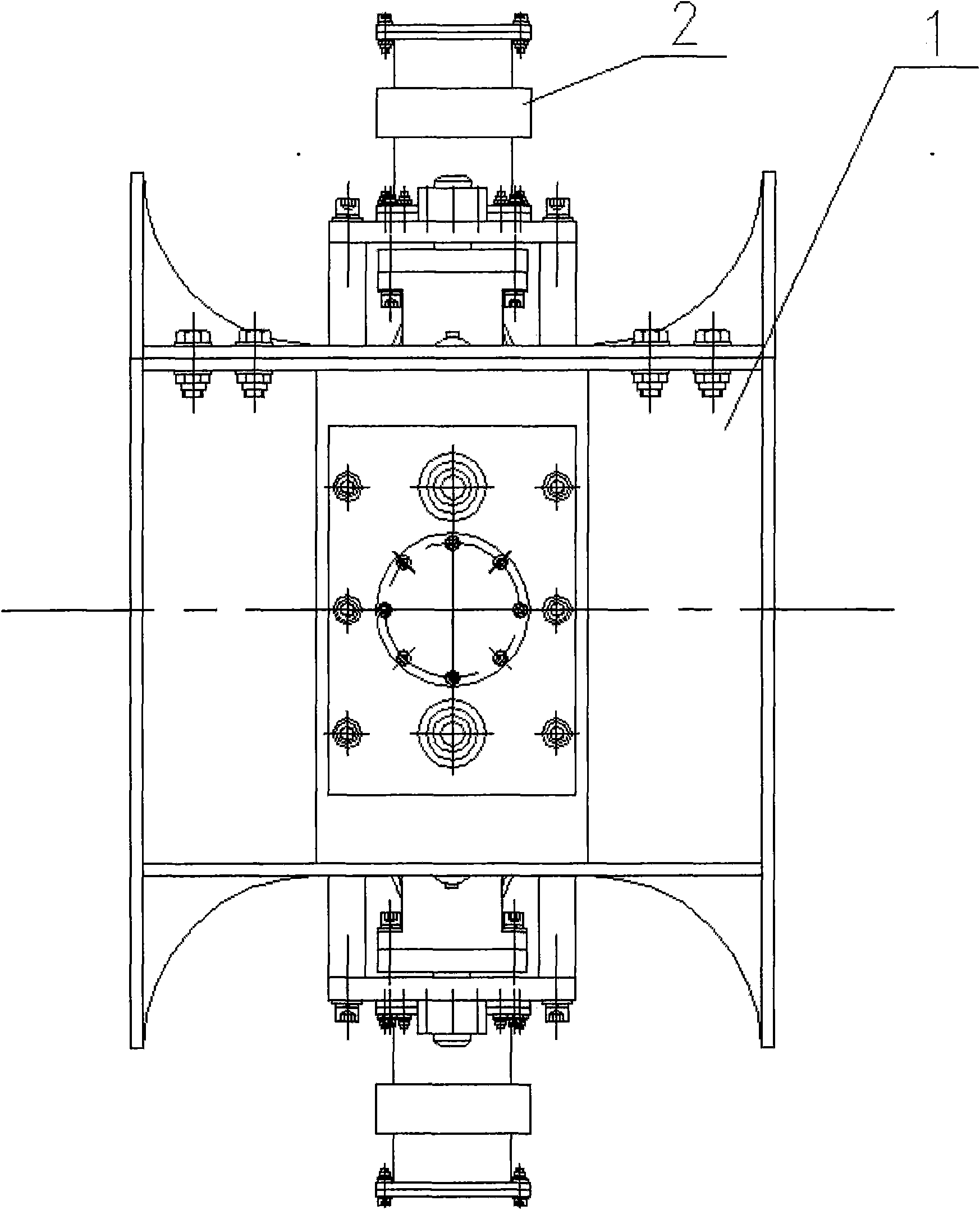

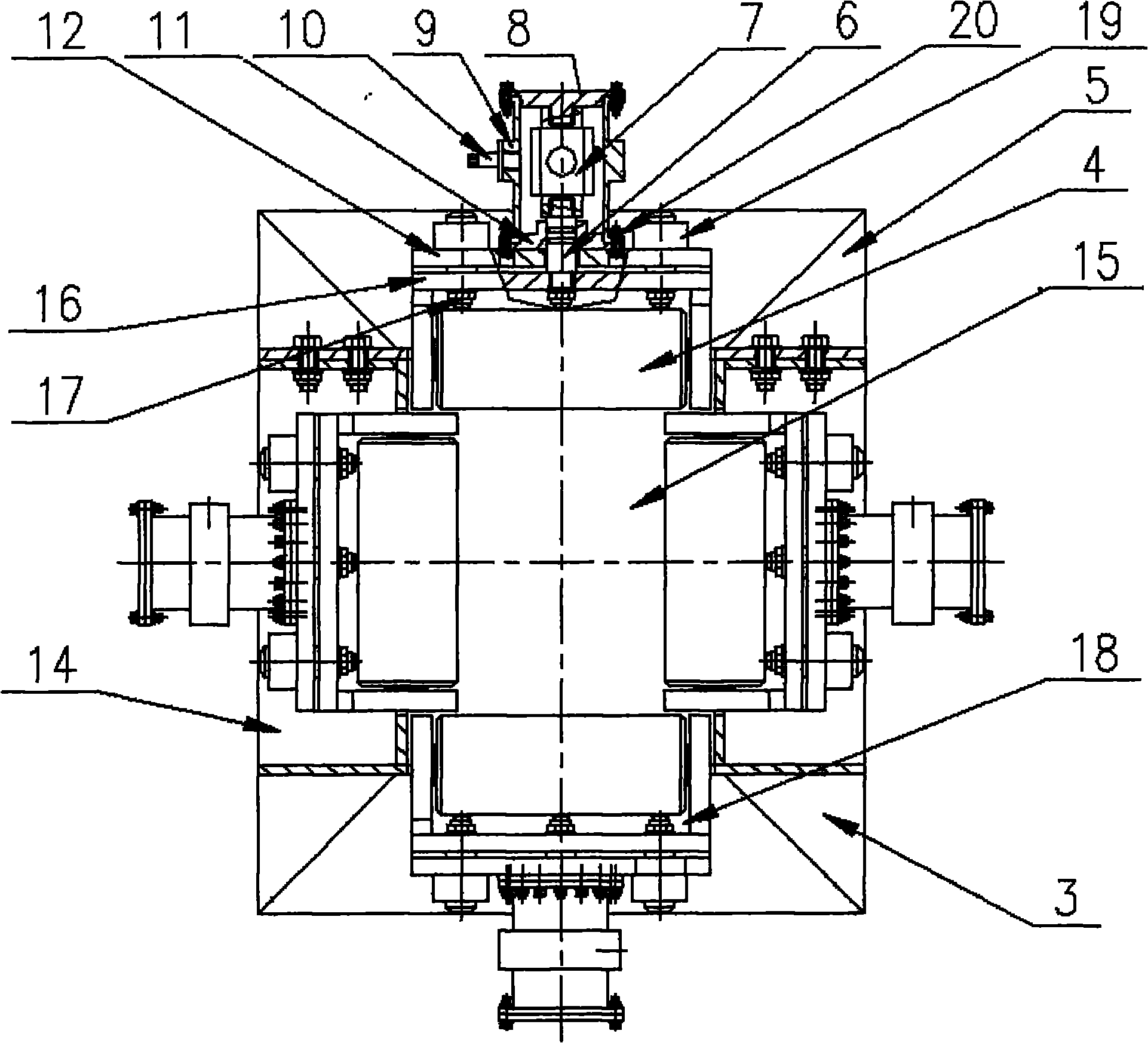

[0018] Embodiment 1: as figure 1 , figure 2 As shown, the present invention includes a guide frame 1 and four force feedback mechanisms 2 connected with the guide frame 1. The guide frame 1 is provided with through holes 15 for passing cables 13 in the axial direction, and is symmetrical in pairs in the radial direction. There are four radial slots 18 communicating with the axial through holes in a cross shape. The four force feedback mechanisms 2 are installed in the radial slots 18 and extend into the axial through holes 15. When in use, the cables 13 pass through Through the axial through hole 15 of the guide frame 1, the signal output terminals of the four force feedback mechanisms 2 communicate with the external control system respectively.

[0019] Such as figure 2 As shown, the force feedback mechanism 2 includes a roller 4, a tension pressure sensor 7, a guiding and fixed base plate 12, a sealed cabin body 9, a roller bracket 16 and a connecting stud 6, and the ten...

Embodiment 2

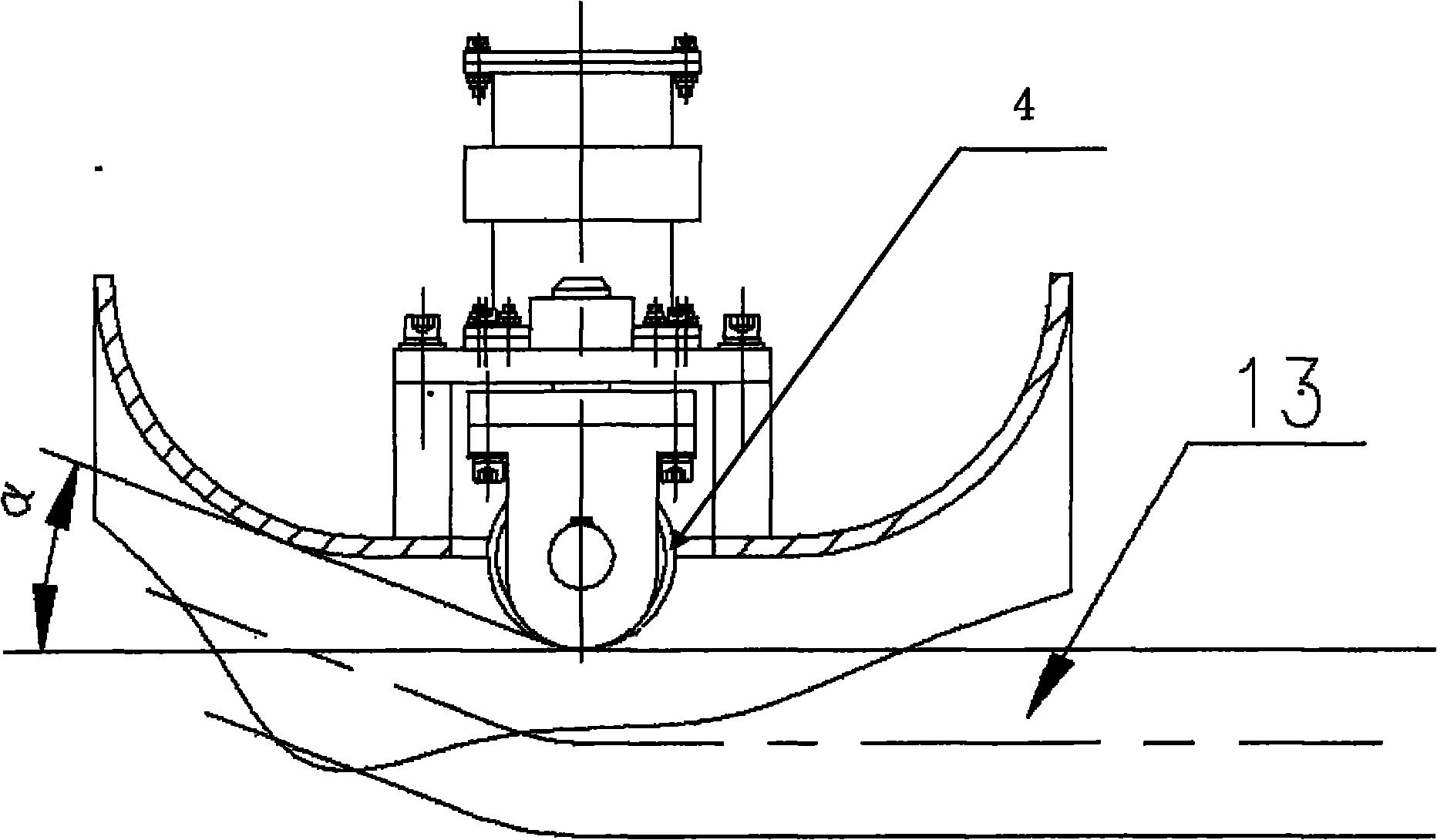

[0026] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, except that the angle α between the roller 4 of the force feedback mechanism 2 and the cable 13 and the tangent line of the arc surface of the guide frame 1 is 20°.

Embodiment 3

[0027] Embodiment 3: The structure of this embodiment is the same as that of Embodiment 1, except that the angle α between the roller 4 and the cable 13 of the force feedback mechanism 2 and the arc tangent of the guide frame 1 is 22°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com