Electric water pump with efficient heat dissipation and vibration reduction structure

A technology of electric water pump and vibration damping structure, which is applied to components, pumps, pump devices and other directions of pumping devices for elastic fluids, can solve problems such as flow loss, vibration generation, poor cooling effect, etc., and achieve high reliability. , The effect of enhancing heat dissipation efficiency and suppressing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: an electric centrifugal pump.

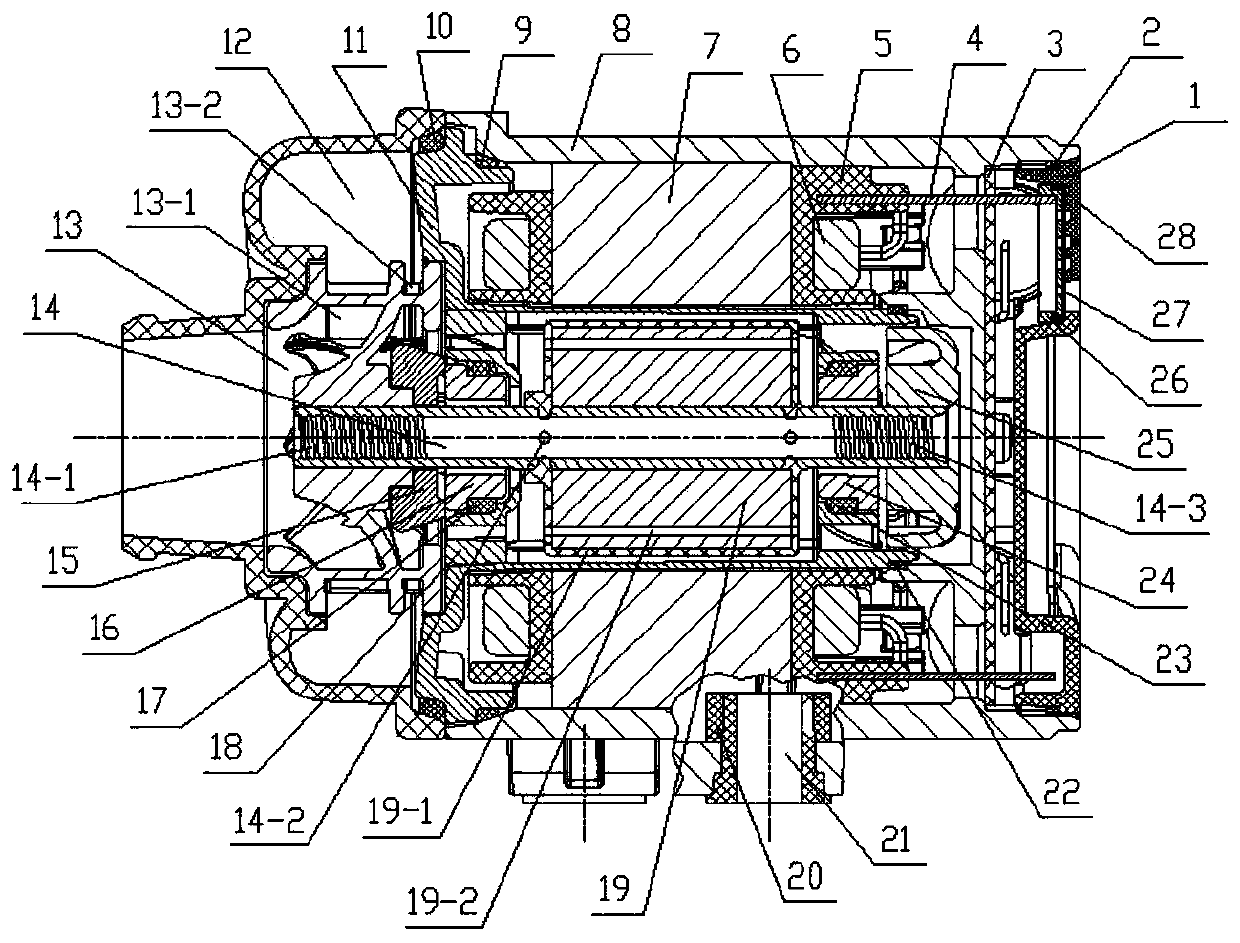

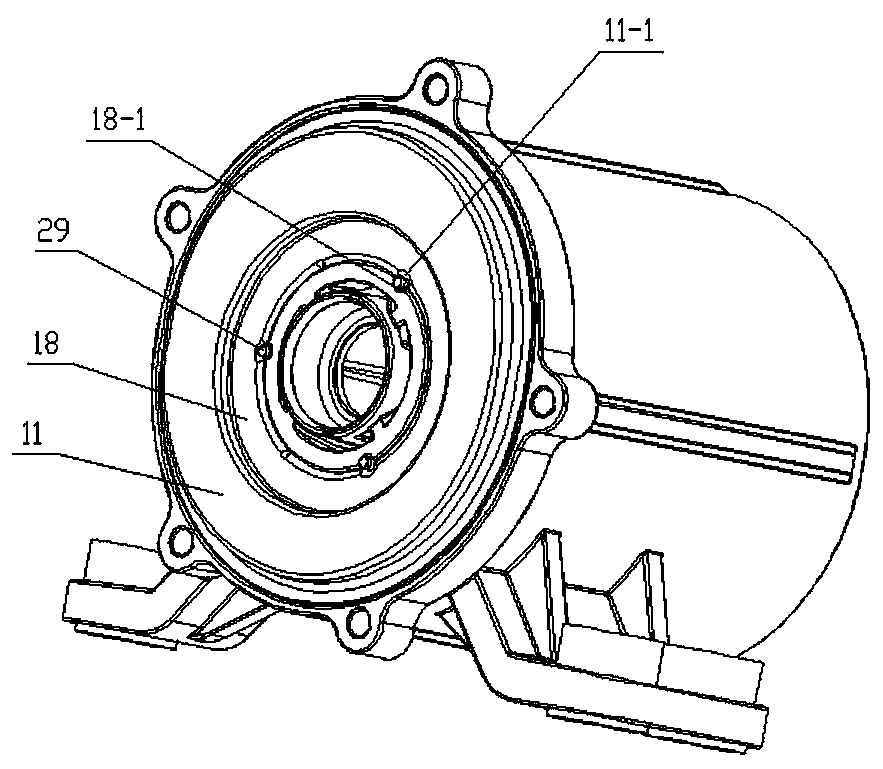

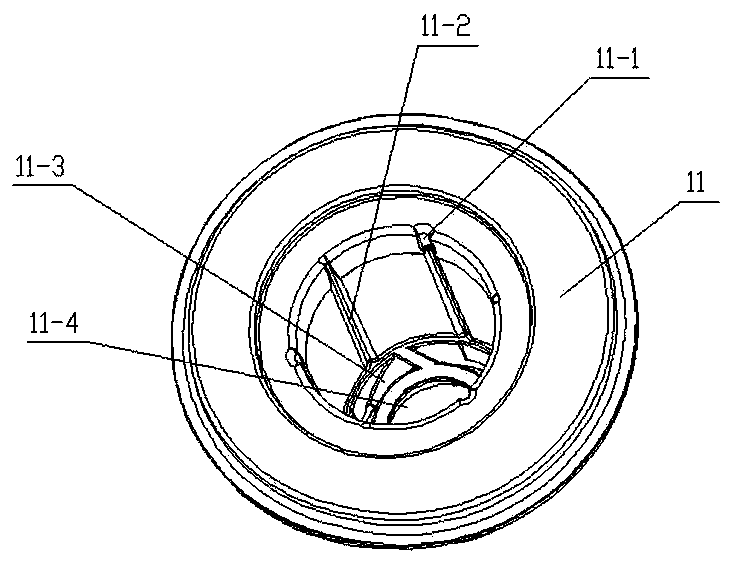

[0036] refer to Figure 1 to Figure 12 As shown, an electric water pump with efficient heat dissipation and vibration reduction structure includes a back cover 1, a back cover sealing ring 2, a water pump controller 3, a coil electrical terminal 4, a stator coil sheath 5, a coil 6, and a motor stator 7 , motor housing 8, inner cover big head sealing ring 9, water pump volute sealing ring 10, inner cover 11, water pump volute 12, water pump impeller 13, motor rotor shaft 14, axial thrust wheel 15, rotor front bearing 16 , Rotor front bearing damping ring 17, bearing seat 18, motor rotor 19, machine foot damping rubber sleeve 20, machine foot damping rubber pad 21, inner cover small head sealing ring 22, rotor rear bearing damping ring 23, rotor Rear bearing 24, axial flow pilot impeller 25, suction device support 26, breathable membrane 27, respirator sealing ring 29 and elastic cylindrical pin 29;

[0037] An organic foot sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com