Oxymethylene polymers, method for the production thereof, and use of same

A formaldehyde polymer and formaldehyde technology, applied in the field of new formaldehyde polymers, can solve the problem of limited polymer yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

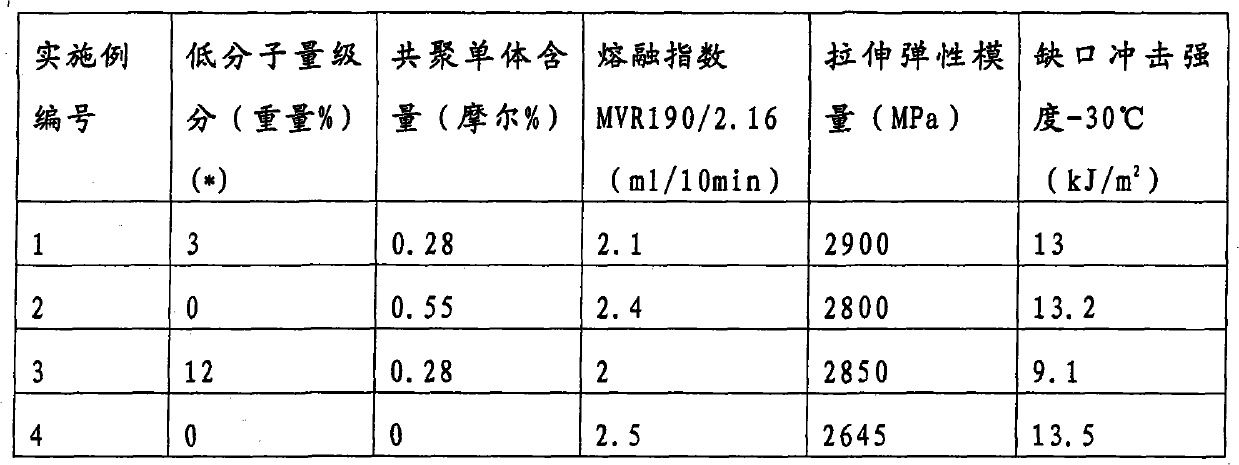

Examples

Embodiment 1

[0037] Embodiment 1 (according to the present invention)

[0038] The polymerization was carried out in a gas-tight, pressure-stabilized twin-screw extruder with 7 individually adjustable heating stages (=zones 1-7) of approximately equal length. The starting compounds are metered in by means of an HPLC pump and mixed efficiently in a premixing zone by static mixing elements before they are fed into an extruder for polymerization. The passivating agent used was a mixture of 0.2% by weight of triethylamine in 1,3-dioxolane. This solution was metered between zones 5 and 6 at a delivery rate of 40 g / h.

[0039] Preheat 4kg / h to 80℃ Alkanes and 4 g / h of methylal in which 300 ppm trifluoromethanesulfonic acid and 600 ppm triethylammonium hydrogentrifluoromethanesulfonate had been dissolved were pumped into the extruder at a shaft speed of 120 rpm. The pressure was kept constant at 18 bar by a pressure regulator valve at the end of the extruder. The temperature of each heating ...

Embodiment 5

[0050] Example 5: Separation of low molecular weight components from oxymethylene polymers

[0051] 4 g of an oxymethylene polymer having a melt index MVR of 2.5 ml / 10 min and a proportion of the low molecular weight fraction of 10% by weight were placed in an autoclave in 40 g of a mixture of 85% by weight methanol, 15% by weight water and 500 ppm triethylamine Heat with stirring for 10 min to 170 °C. After cooling to room temperature (without stirring), the upper cloudy liquid was separated from the coarse polymer particles at the bottom by brief decantation. After drying, the coarse polymer particles had a weight of 3.4 g and a low molecular weight fraction of 5% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com