Emulsions of dilatant organopolysiloxanes

A polysiloxane, organo-based technology in the field of emulsions of dilatant organopolysiloxanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

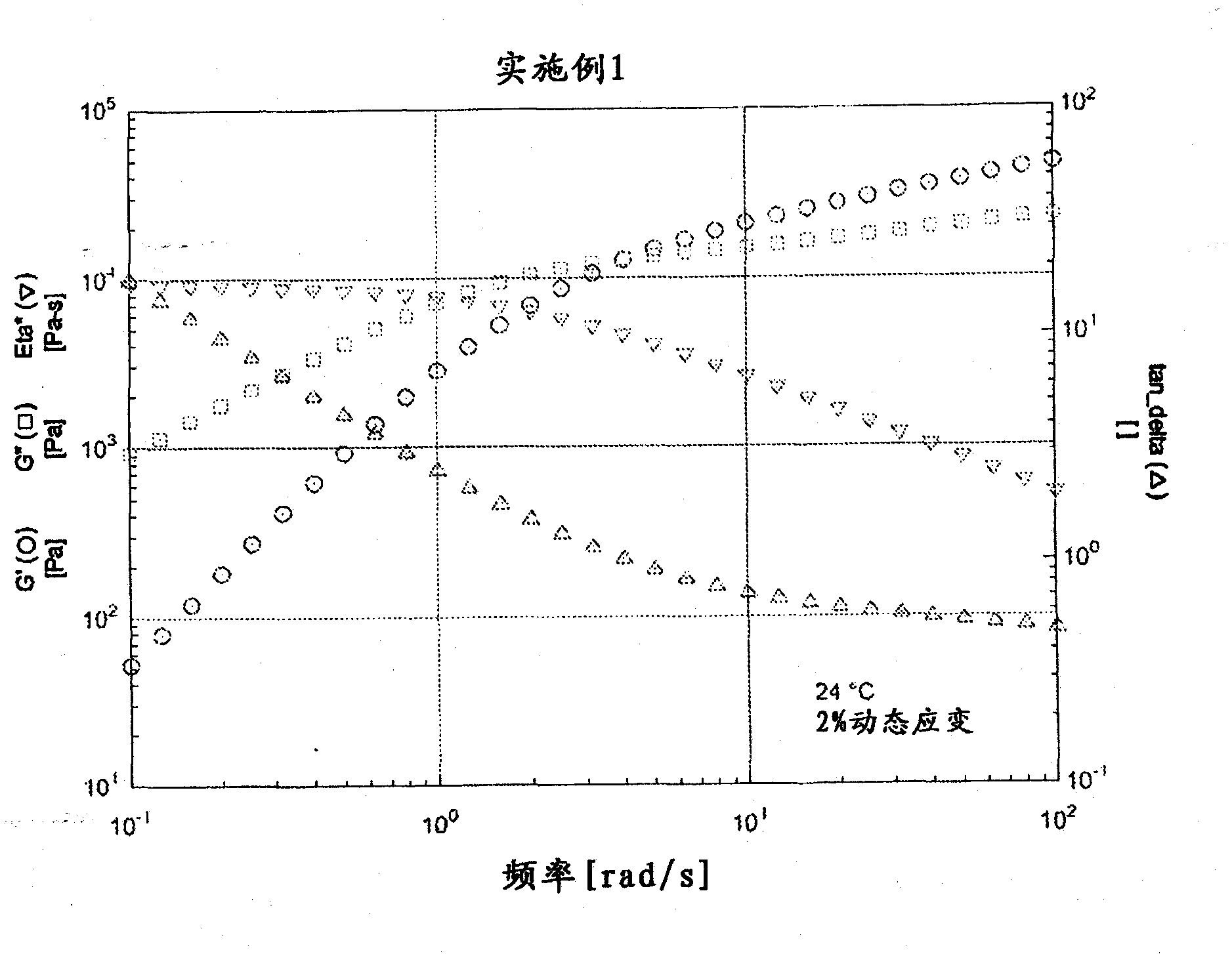

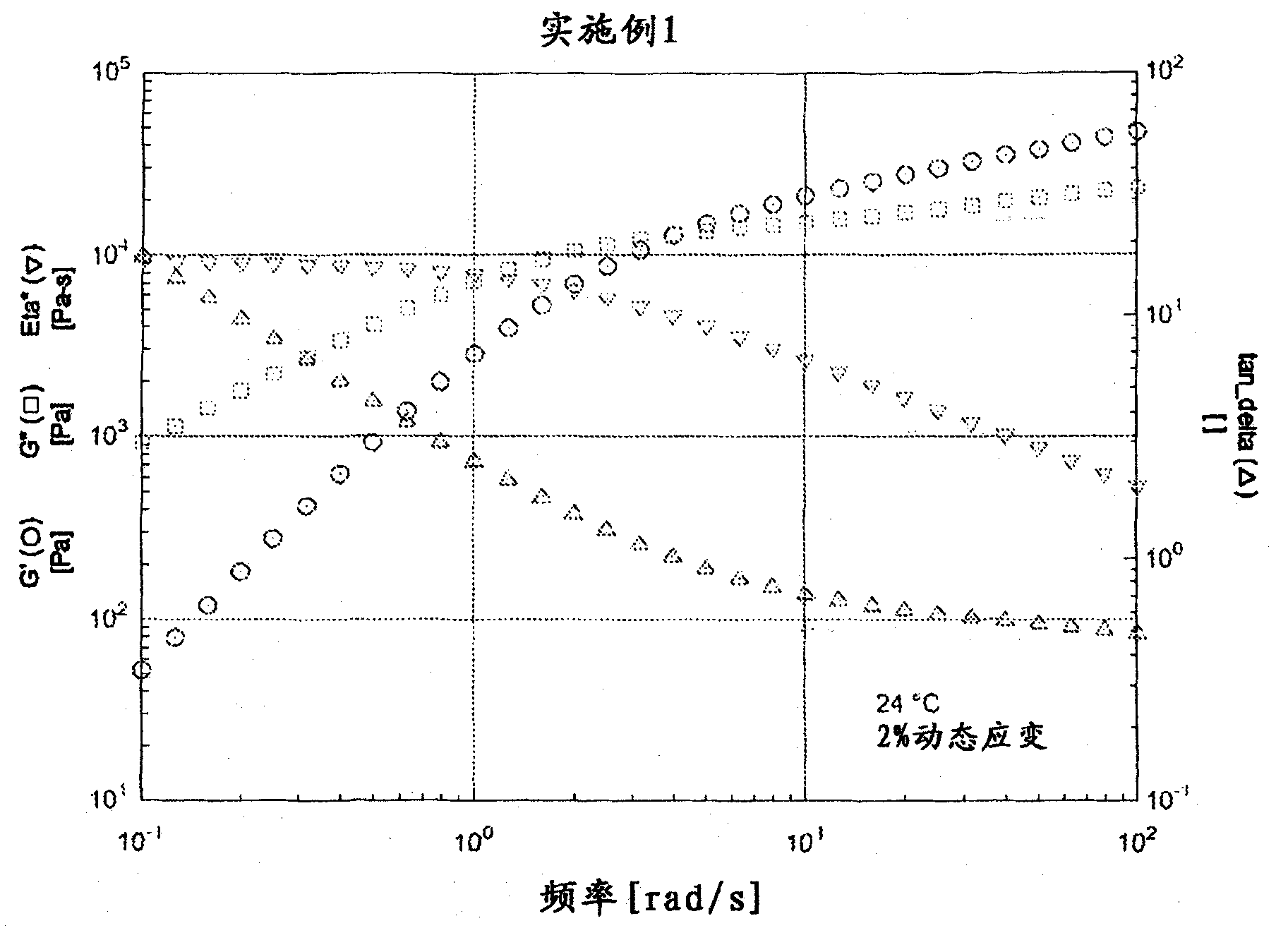

Embodiment 1

[0079] First, 50 g of Me with a viscosity of about 50000 mPa·s (cP) and a number average 2 SiOH-terminated dimethylpolysiloxane was weighed into a max 100 cup followed by the addition of 0.10 g of 50 wt % trimethylsiloxy-terminated polydimethylsiloxane fluid having a kinematic viscosity of about 1000 cSt. boric acid dispersion. Close the cup and place it in the Speedmixer DAC 150 mixer, and at maximum speed, spin the cup for 20 seconds. The cup was allowed to remain undisturbed for 15 minutes, after which time the cup was spun again at maximum speed for 20 seconds. After standing for an additional 10 minutes, the cup was swirled again for 20 seconds. Immediately after the preceding rotation, 0.75 g of lauryl alcohol (4) ethoxylate (Brij 30), followed by the addition of 1.5 g of 72% lauryl alcohol (23) ethoxylate (Brij 35 L) of aqueous solution and 0.60 g of deionized (DI) water. Close the cup and place in the Speedmixer Spin inside for 20 seconds. The contents of t...

Embodiment 2

[0081] Using the same procedure as described in Example 1, 0.75 g of lauryl alcohol (4) ethoxylate (Brij 30), 1.5g 72% lauryl alcohol (23) ethoxylate (Brij 35 L) of aqueous solution and 0.60 g of deionized (DI) water, emulsified by 50 g of Me 2 SiOH-terminated polydimethylpolysiloxane, 0.11 g of a composition prepared from a 50 wt% boric acid dispersion in a trimethylsiloxy-terminated polydimethylsiloxane fluid having a kinematic viscosity of about 1000 cSt. Using the same procedure as Example 1, the emulsion viscous phase was incrementally diluted with a total of 31 g DI water. The average particle size of the emulsion is about 0.75 μm.

Embodiment 3

[0083] Using the same procedure and amounts as described in Example 2, except that the amount of boron oxide dispersion in polydimethylsiloxane was used, an emulsion was prepared. Use 50gMe 2 This emulsion was prepared from SiOH terminated polydimethylpolysiloxane and 0.40 g boron oxide / polydimethylsiloxane dispersion. The average particle size of the emulsion is about 0.75 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap