Apparatus for metering printing ink

A technology for printing ink and supporting devices, which is applied in printing, general parts of printing machinery, printing presses, etc., and can solve problems such as wear, machine damage, and mechanical contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

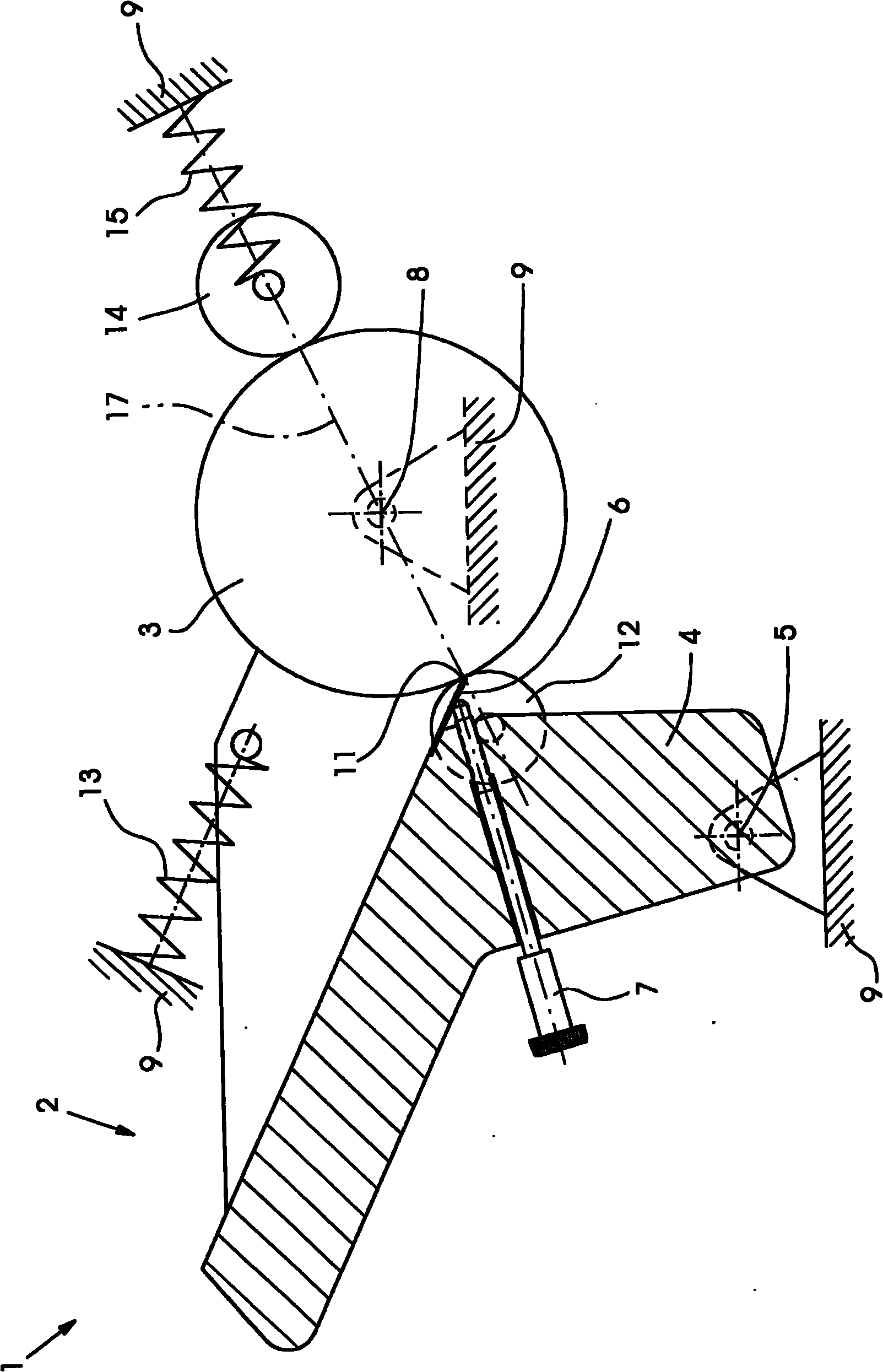

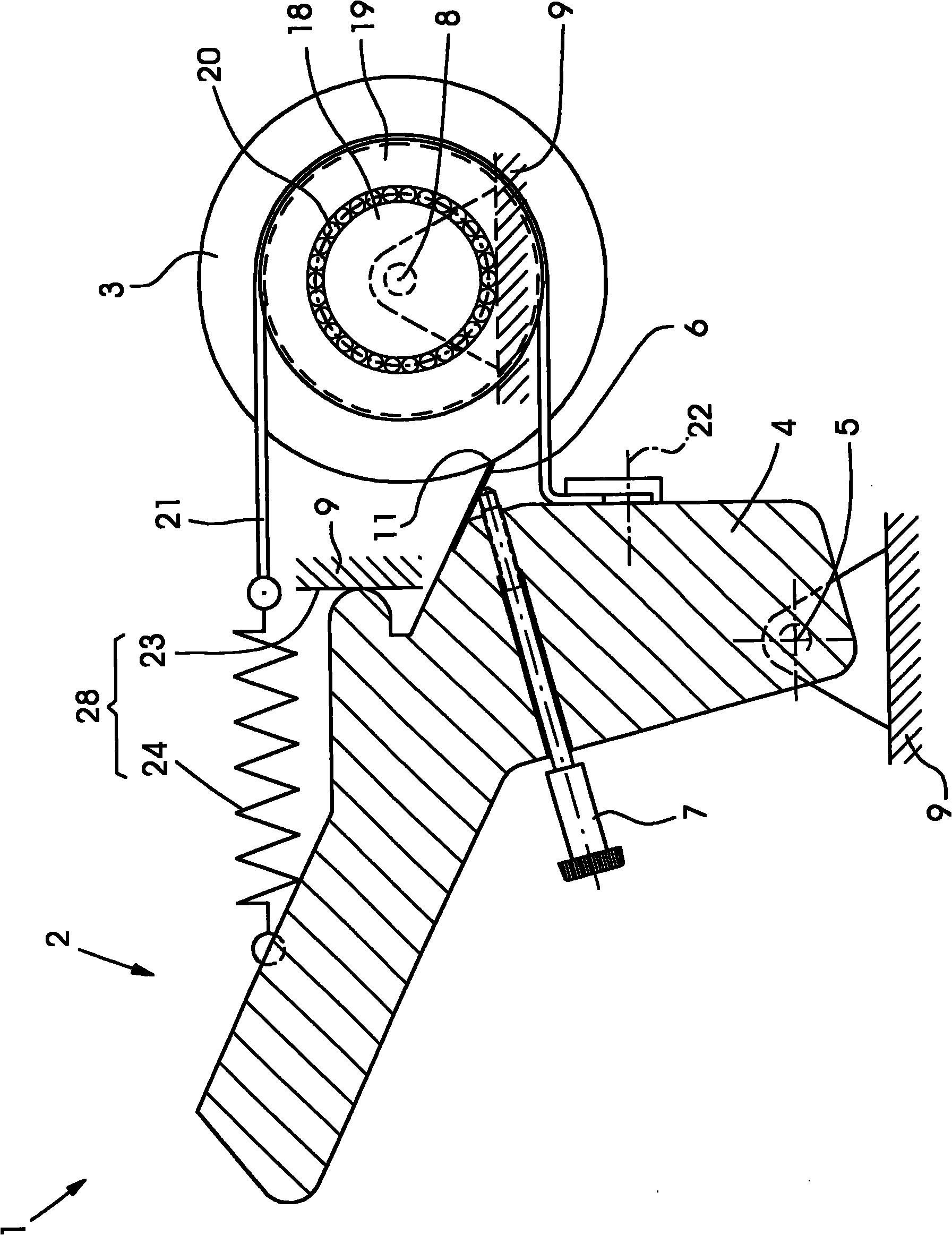

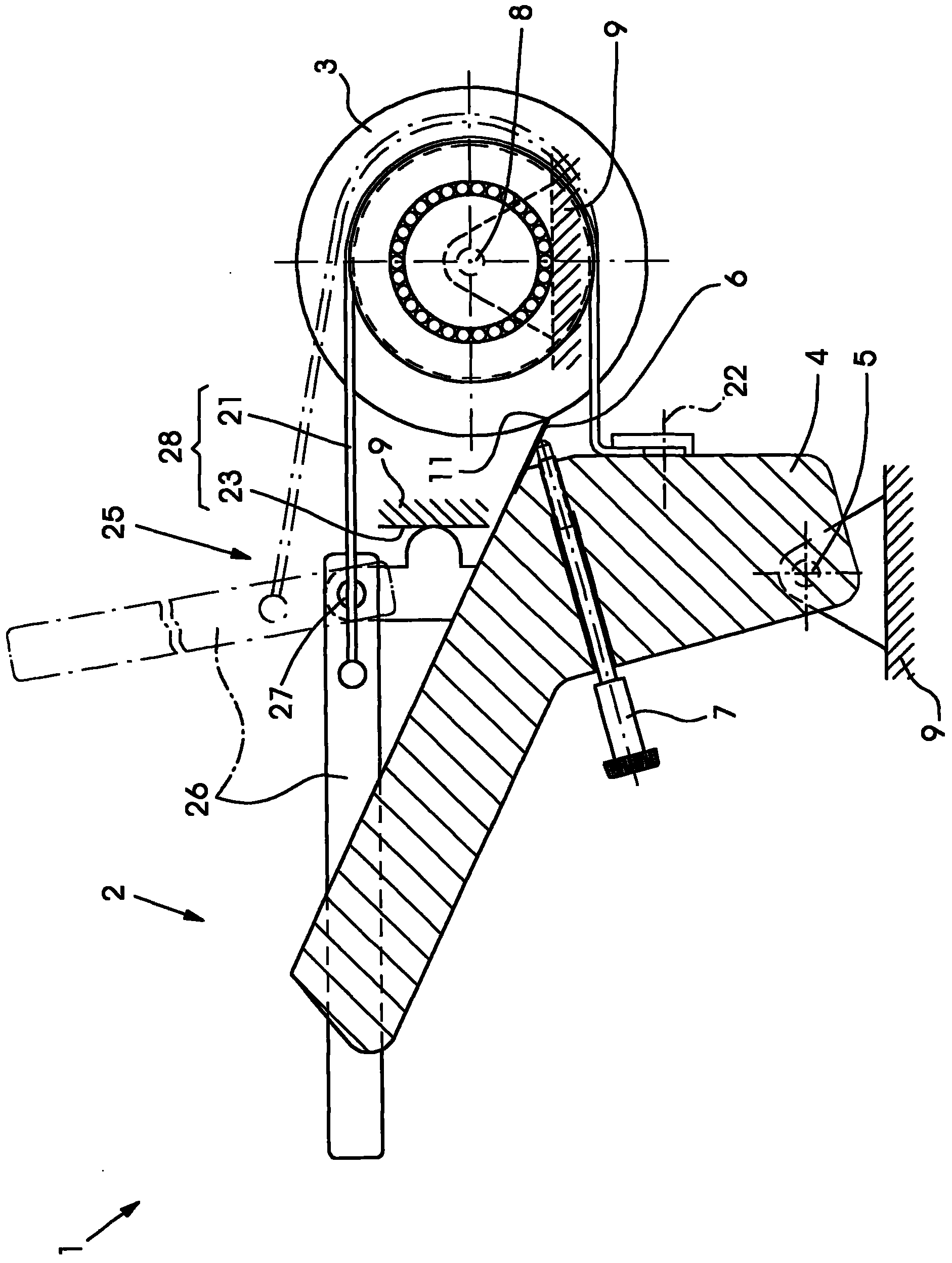

[0030] exist Figures 1 to 6 In , elements and components corresponding to each other are denoted by the same reference numerals.

[0031] exist Figures 1 to 3 A printing press 1 with an inking unit 2 is shown in each case in a partial view. The printing press 1 is an offset printing press for printing sheets.

[0032] This partial illustration shows the ink fountain roller 3 and the ink fountain 4 of the inking unit 2 . In addition, the inking unit 2 also includes an ink application roller rolling on the printing plate, an axially moving spreading roller and a transfer roller, which are not shown in the figure. If the inking unit 2 is a roller inking unit, it consists of a blotter roller in periodic contact with the fountain roller 3, and if the inking unit 2 is a thin-film inking unit, it consists of feeding the printing ink from the fountain roller 3. A milled film roll whose peripheral speed is substantially equal to the peripheral speed of the printing plate.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com