Antiflaming PVC (poly vinyl chloride)/ABS (acrylonitrile butadiene styrene) alloy material and preparation method thereof

An alloy material and PVC resin technology, which is applied in the field of modification and preparation of flame-retardant PVC/ABS alloy materials, can solve the problems such as the inability to effectively guarantee the compatibility of PVC resin and ABS resin, material performance decline, poor processability, etc. Achieve the effect of improving processing stability, improving low temperature impact performance and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

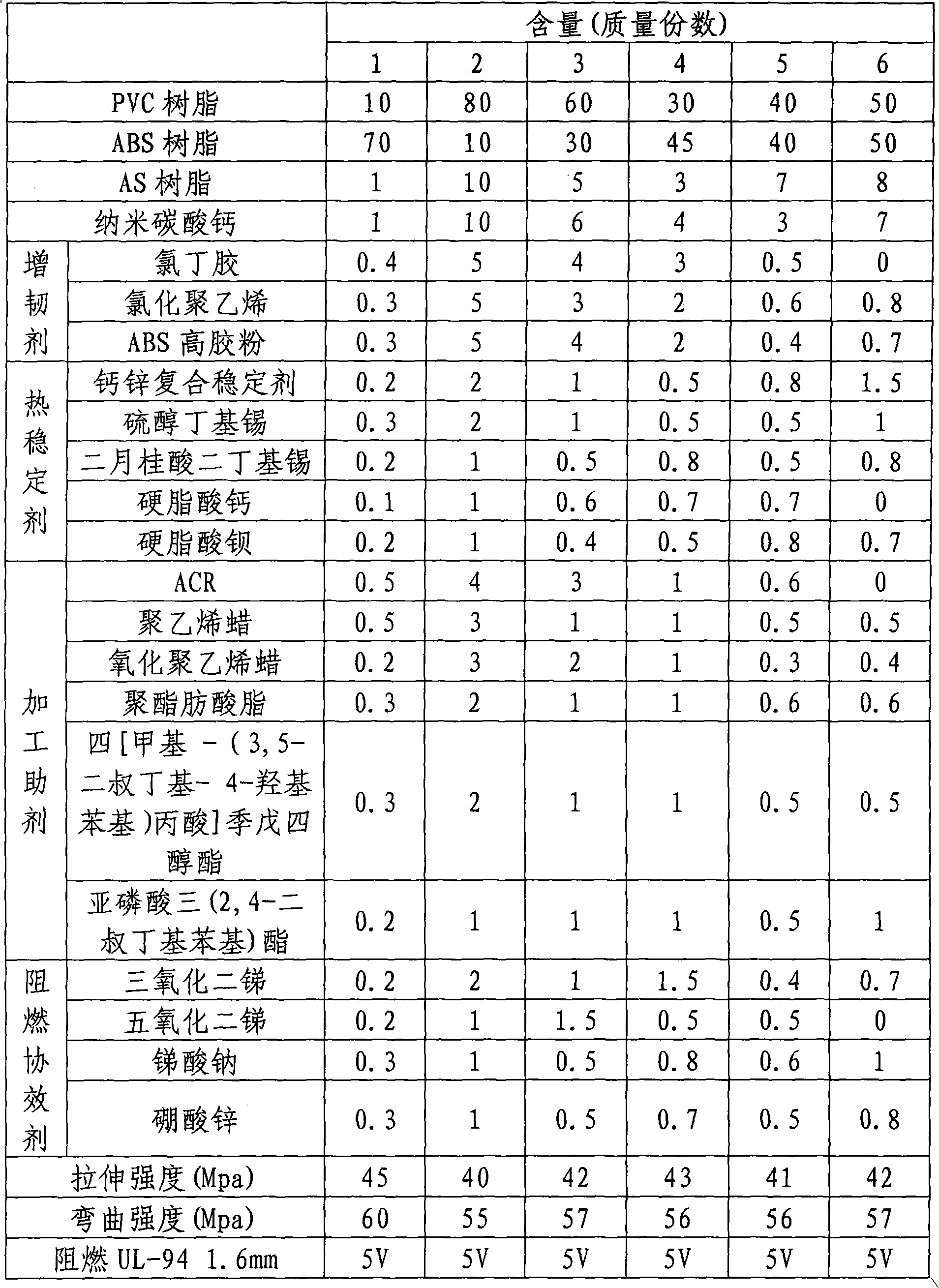

Embodiment 1

[0031] The flame-retardant PVC / ABS alloy material of the present invention is made of PVC resin, ABS resin, AS resin, nano-calcium carbonate, neoprene, chlorinated polyethylene, ABS high-glue powder, calcium-zinc composite stabilizer, mercaptan butyl tin, dilaurel Dibutyltin acid, calcium stearate, barium stearate, ACR, polyethylene wax, oxidized polyethylene wax, polyester fatty acid ester, tetrakis [methyl-(3,5-di-tert-butyl-4-hydroxybenzene Base) propionic acid] pentaerythritol ester, tris (2,4-di-tert-butylphenyl) phosphite, antimony trioxide, antimony pentoxide, sodium antimonate and zinc borate. The above ingredients are calculated according to mass fraction: 10 parts of PVC resin; 70 parts of ABS resin; 1 part of AS resin; 1 part of nano-calcium carbonate; 0.4 part of neoprene; 0.3 part of chlorinated polyethylene; 0.2 parts of calcium zinc composite stabilizer; 0.3 parts of butyltin mercaptide; 0.2 parts of dibutyltin dilaurate; 0.1 parts of calcium stearate; 0.2 parts...

Embodiment 2

[0039]The flame-retardant PVC / ABS alloy material of the present invention is made of PVC resin, ABS resin, AS resin, nano-calcium carbonate, neoprene, chlorinated polyethylene, ABS high-glue powder, calcium-zinc composite stabilizer, mercaptan butyl tin, dilaurel Dibutyltin acid, calcium stearate, barium stearate, ACR, polyethylene wax, oxidized polyethylene wax, polyester fatty acid ester, tetrakis [methyl-(3,5-di-tert-butyl-4-hydroxybenzene Base) propionic acid] pentaerythritol ester, tris (2,4-di-tert-butylphenyl) phosphite, antimony trioxide, antimony pentoxide, sodium antimonate and zinc borate. The above ingredients are calculated according to mass fraction: 80 parts of PVC resin; 10 parts of ABS resin; 10 parts of AS resin; 10 parts of nano calcium carbonate; 5 parts of neoprene; 5 parts of chlorinated polyethylene; 2 parts of calcium zinc composite stabilizer; 2 parts of butyltin mercaptide; 1 part of dibutyltin dilaurate; 1 part of calcium stearate; 1 part of barium s...

Embodiment 3

[0047] The flame-retardant PVC / ABS alloy material of the present invention is made of PVC resin, ABS resin, AS resin, nano-calcium carbonate, neoprene, chlorinated polyethylene, ABS high-glue powder, calcium-zinc composite stabilizer, mercaptan butyl tin, dilaurel Dibutyltin acid, calcium stearate, barium stearate, ACR, polyethylene wax, oxidized polyethylene wax, polyester fatty acid ester, tetrakis [methyl-(3,5-di-tert-butyl-4-hydroxybenzene Base) propionic acid] pentaerythritol ester, tris (2,4-di-tert-butylphenyl) phosphite, antimony trioxide, antimony pentoxide, sodium antimonate and zinc borate. The above ingredients are calculated according to mass fraction: 60 parts of PVC resin; 30 parts of ABS resin; 5 parts of AS resin; 6 parts of nano-calcium carbonate; 4 parts of neoprene; 3 parts of chlorinated polyethylene; 1 part of calcium-zinc composite stabilizer; 1 part of butyltin mercaptide; 0.5 part of dibutyltin dilaurate; 0.6 part of calcium stearate; 0.4 part of bariu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com