Method for improving surface quality of strip steel after pickling by pickling line

A technology of pickling unit and rear surface, applied in the field of metal material processing, can solve problems such as surface yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

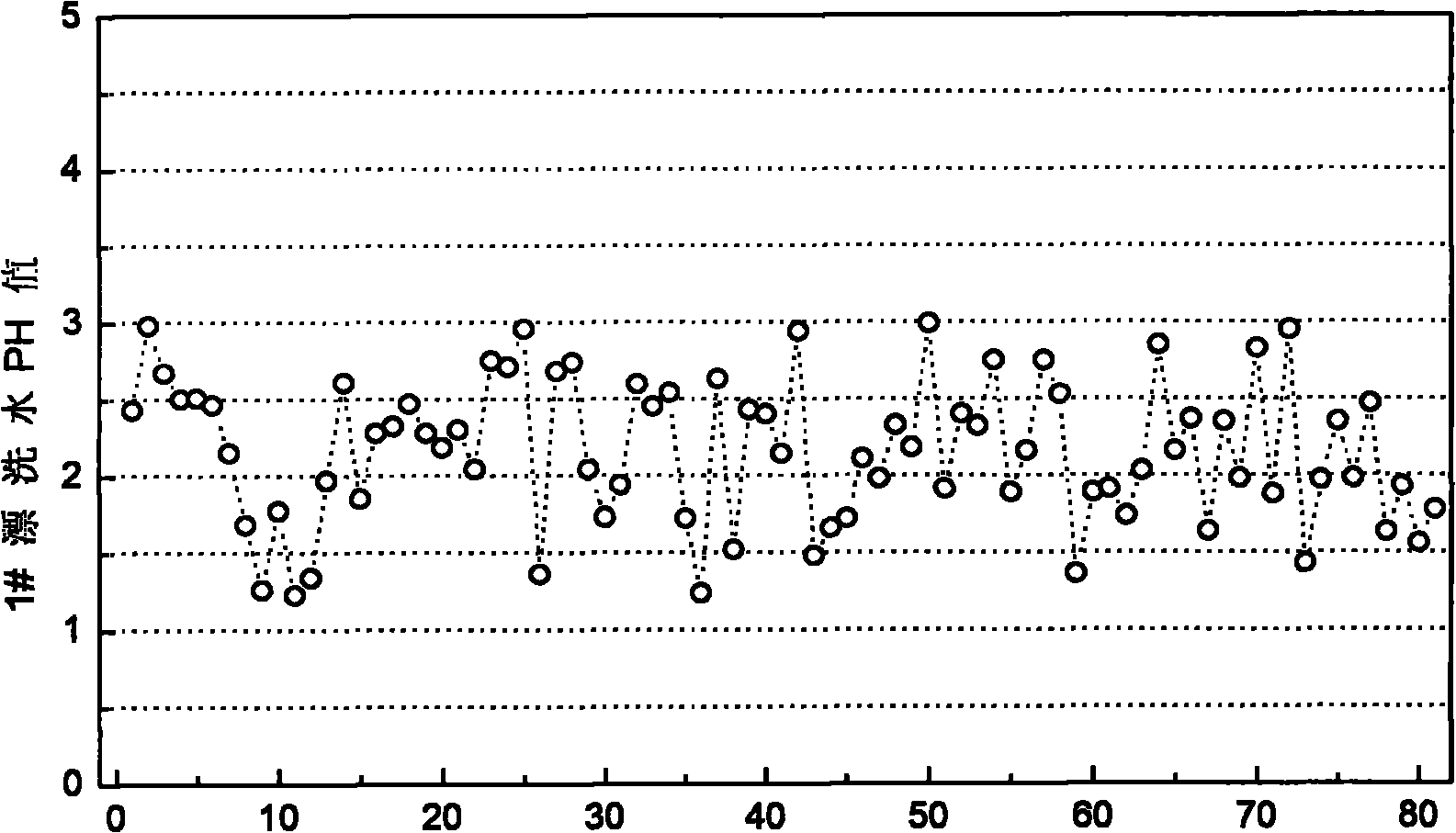

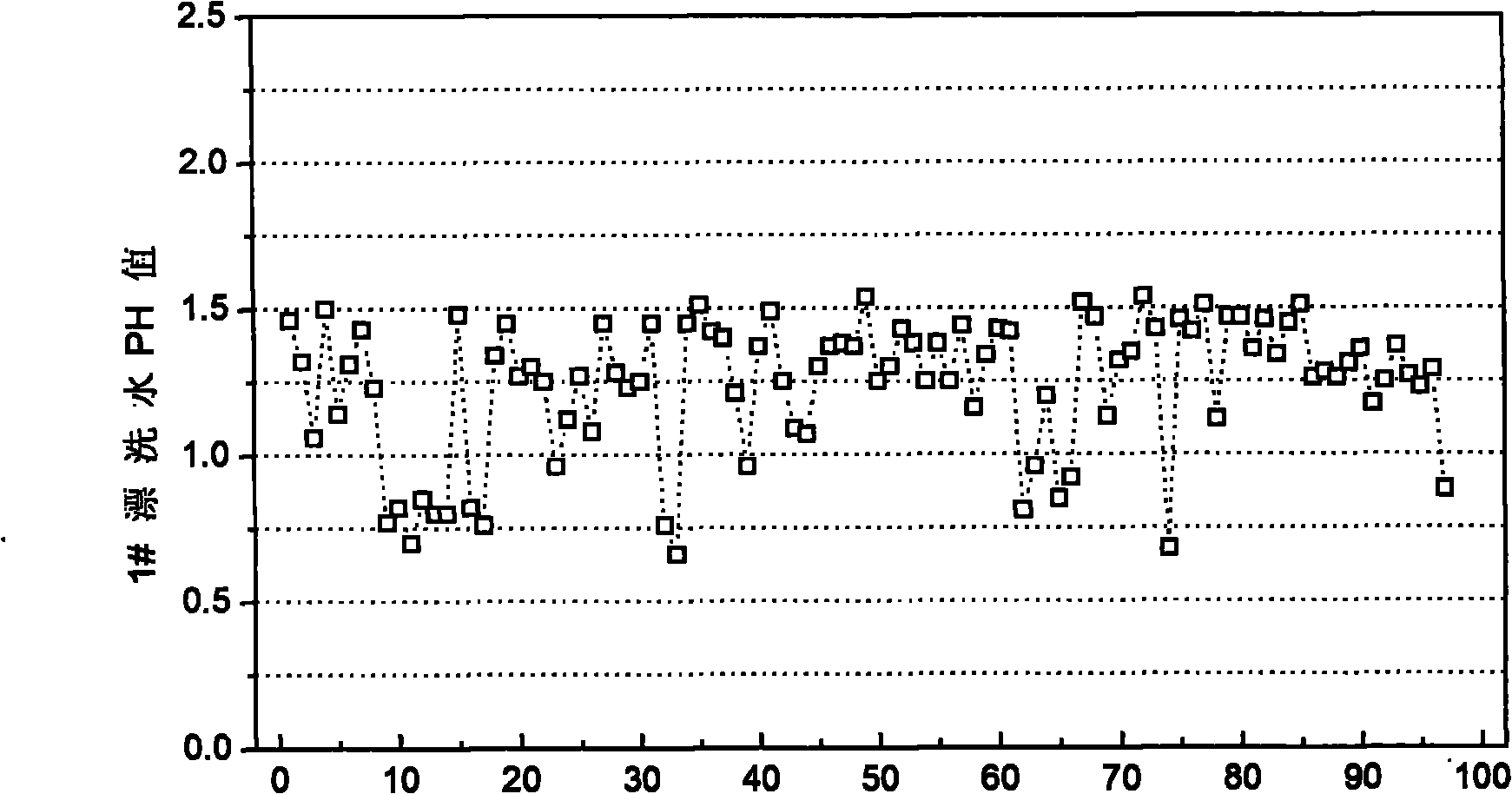

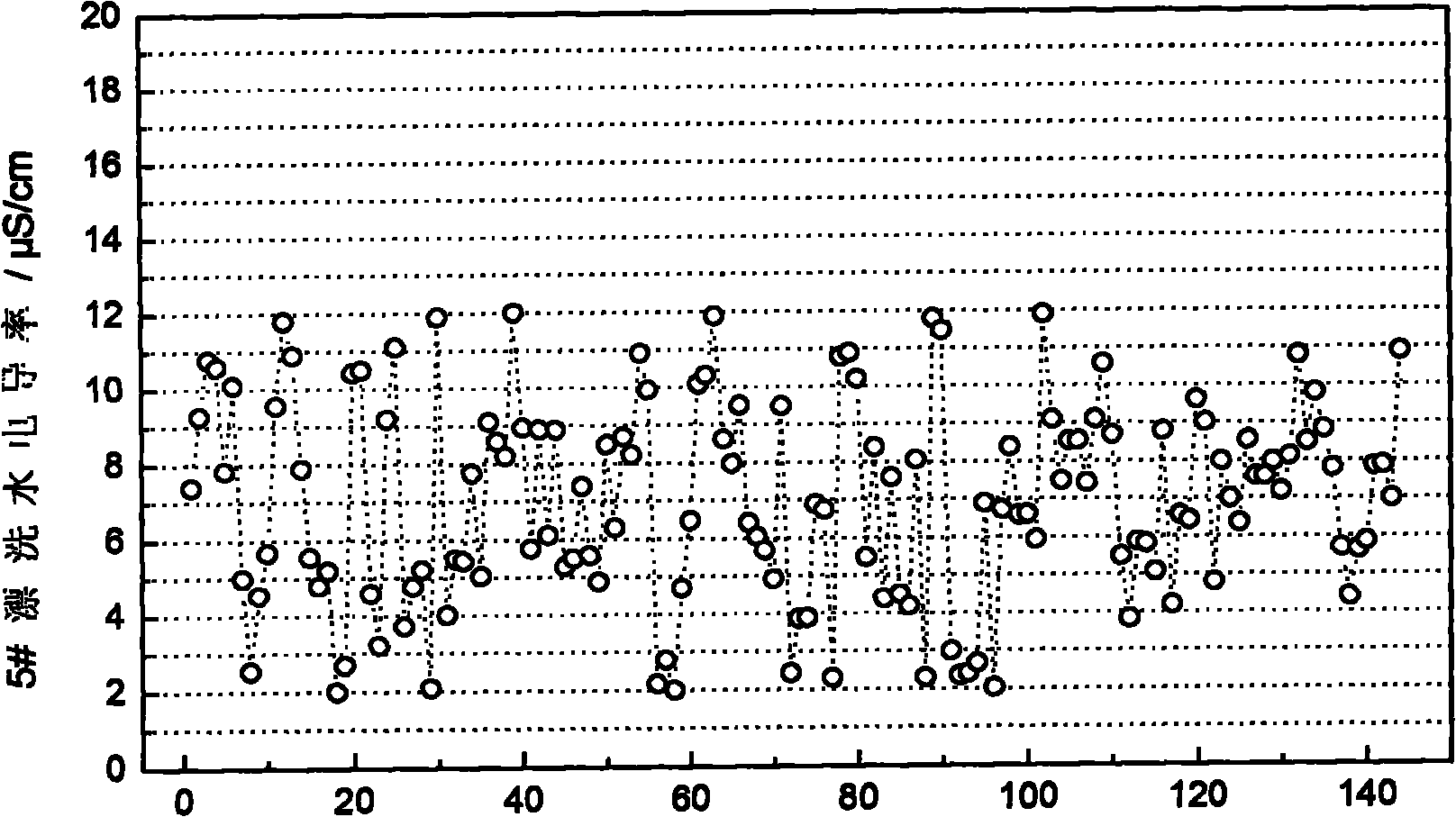

[0027] As mentioned above: firstly, turn off the pre-rinsing section; secondly, increase the conductivity of the rinsing water in the 5# rinsing tank appropriately, from <10μS / cm before optimization to 10-20μS / cm after optimization (stable operation The actual measured values on the following day are 16.4μS / cm, 19.8μS / cm, 12.7μS / cm, 12.8μS / cm, 19.4μS / cm and 17.2μS / cm); finally, reduce the rinse water temperature appropriately, and the 5# rinse water The temperature setting value was reduced from 65°C before optimization to 40-50°C after optimization (actually measured points were 42, 44, 45, 48, 50°C). It effectively alleviates the problem of yellowing of the surface of the strip after pickling and rinsing when the process speed is low, and at the same time reduces the consumption of desalted water to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com