Rotary cylinder plunger hydraulic motor for independently adjusting oil absorption and discharge and torque shift method

An independent adjustment, hydraulic motor technology, applied in the hydraulic pilot switch variable torque rotary cylinder plunger hydraulic motor and variable torque fields, can solve the problems of instability, large variable mechanism stroke, slow response speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

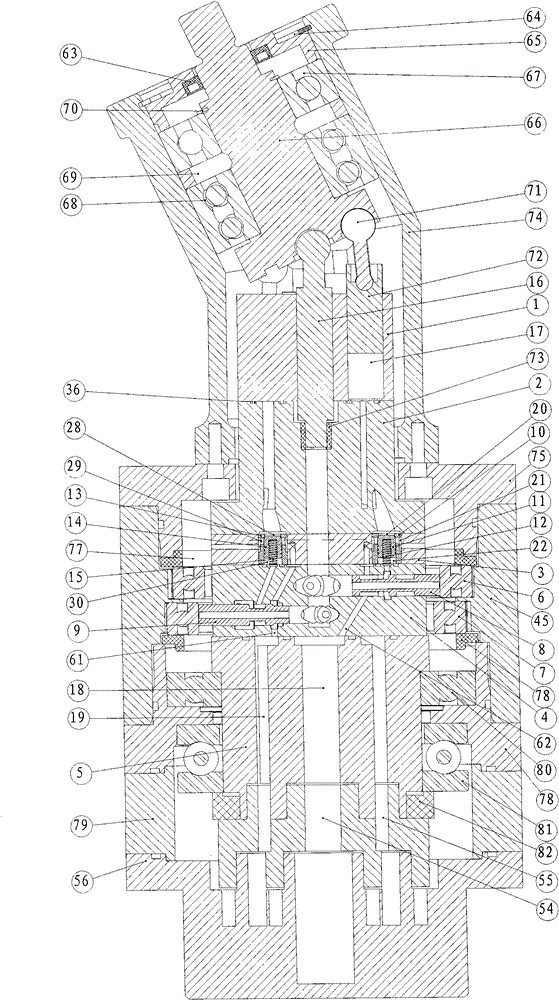

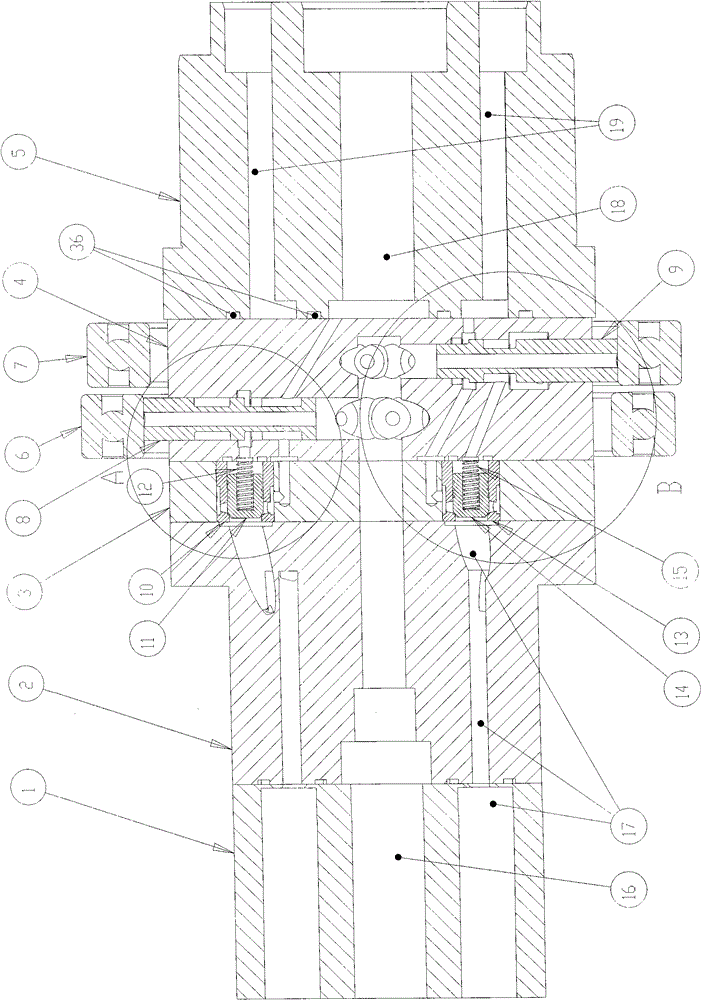

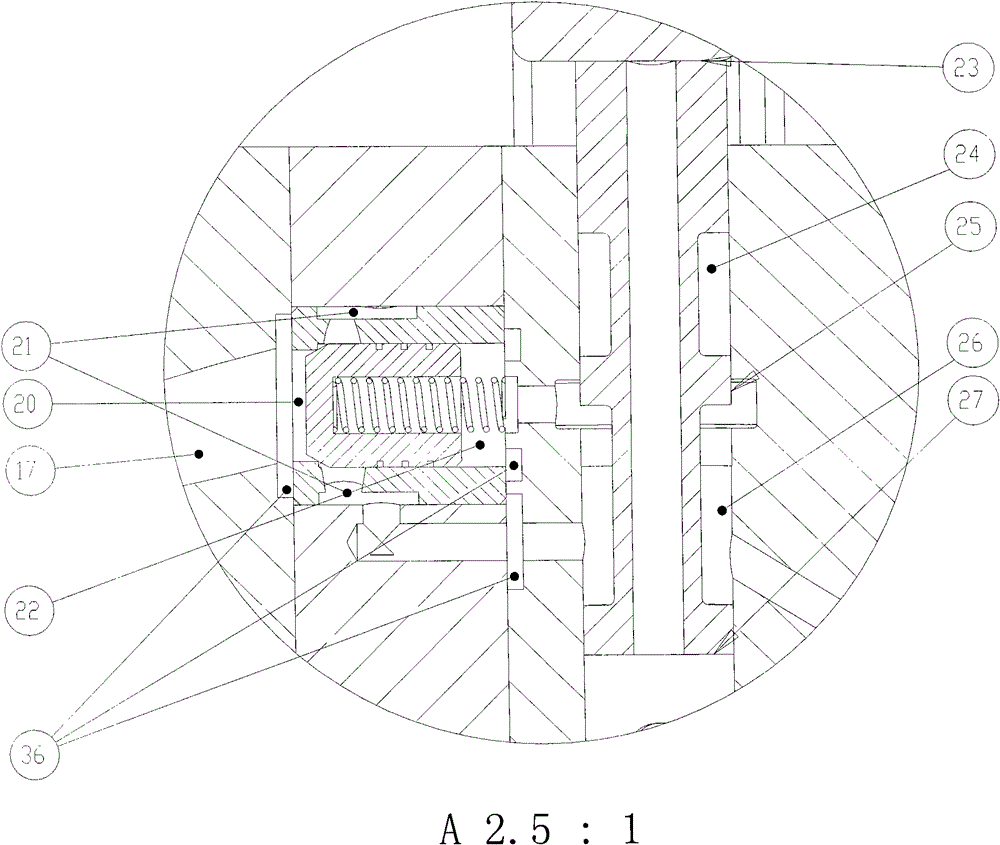

[0084] In conjunction with the accompanying drawings, the present invention will be described in detail below through specific embodiments.

[0085] A kind of machine-hydraulic pilot switch variable torque rotary cylinder plunger hydraulic motor in this specific embodiment is refitted from an ordinary rotary cylinder type quantitative plunger hydraulic motor.

[0086] Remove the back cover and oil distribution plate of the plunger type quantitative hydraulic motor, process the end face of the plunger cylinder into a plane, install the oil distribution assembly of the present invention to the original position of the back cover and oil distribution plate of the hydraulic motor, and the plunger cylinder The cylinder and the oil distribution assembly are connected by pins. An ordinary rotary cylinder plunger type quantitative hydraulic motor has been refitted into a hydraulic motor with a torque-variable function of a machine-hydraulic pilot switch for independent adjustment of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com