Spiral fluid turbine pump

A technology of screw type and turbo pumps, applied in the direction of rotary piston pumps, rotary piston machines, pumps, etc., can solve the problems of fluid working medium pulsation, etc., and achieve the goal of promoting energy saving, resource saving, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

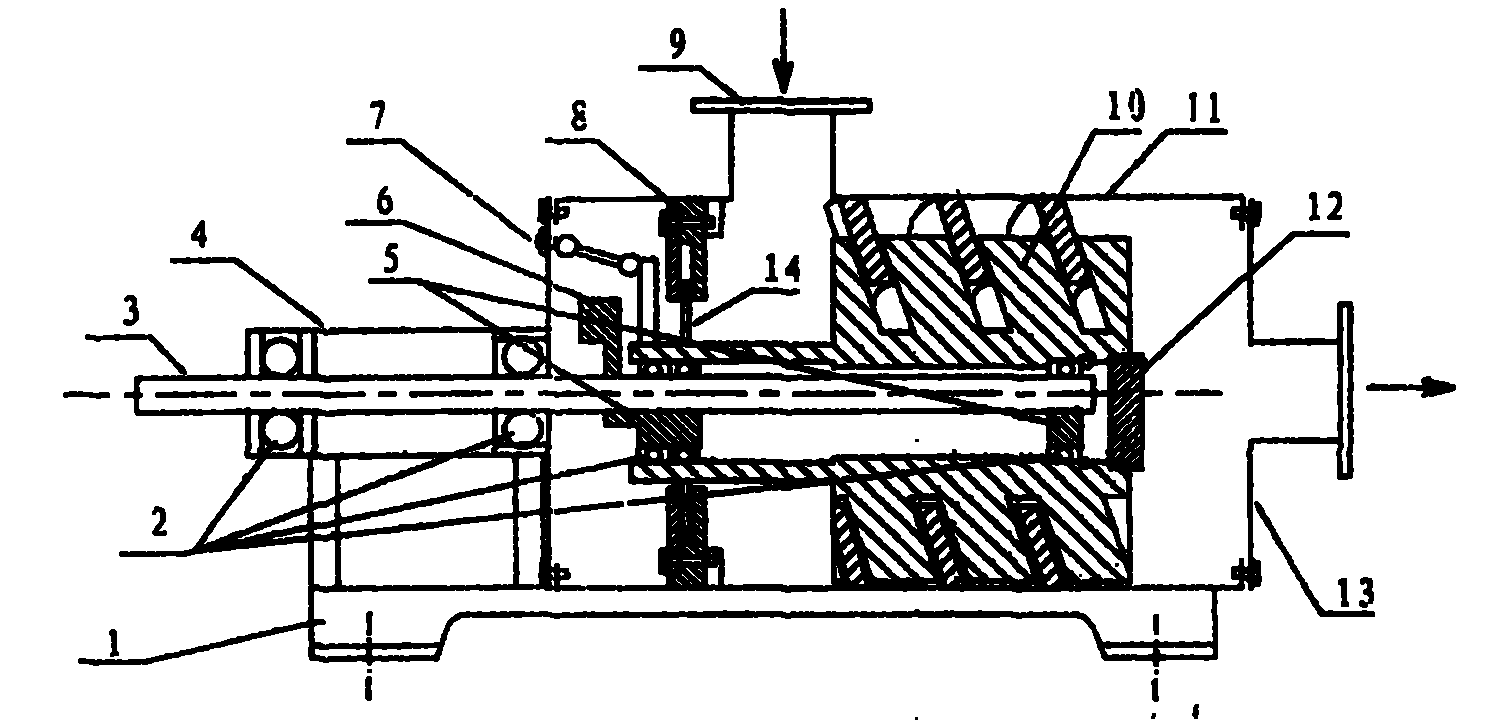

[0026] Screw type fluid turbine pump single screw machine ( figure 1 ), through at least one helicoidal rotor (10) moving in a translational manner in the helical stator (11), work is done on the fluid working medium in the cavity so that the fluid working medium is continuously discharged from the inlet to the outlet or reversed with the fluid working medium The movement mode continuously works on the helical rotor to output power. The structure consists of a machine base (1) connected with a spiral stator (11), a bearing seat (4), a rotor locking device (7), a sealing plate (12), and a power shaft (3) installed on the machine base (1). There are bearings (2), eccentric wheel (5) and balance iron (6) on the upper sleeve, and the spiral rotor (10) is equipped with bearing (2) and fits with the eccentric wheel (5), and is also connected with a sealing device (8) , The rotor locking device (7) is placed in the cylinder of the spiral stator (11), and the spiral stator (11) is al...

Embodiment 2

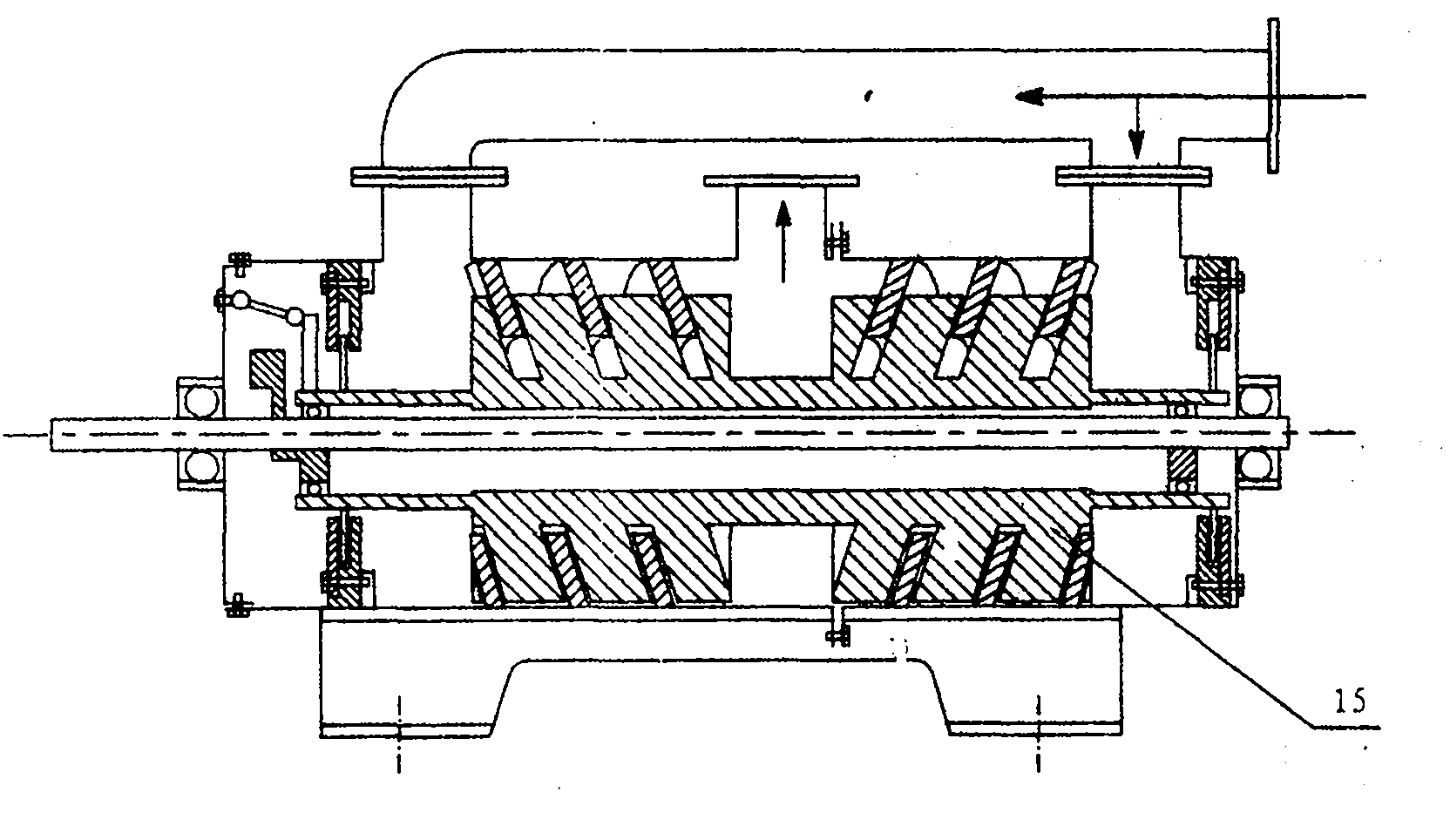

[0034] Helical fluid turbine pump twin-screw machine ( figure 2 ) is an extended model of the basic type of single-screw machine, and its rotor and stator can be two coaxial counter-rotating rotors with two positive and negative rotations matching the stator double-helix structure (15), the purpose of which is to In order to balance the axial thrust, the end cover (16) of the double-screw machine is also embedded with a bearing and receives the power shaft. This model is simple and compact, with good balance and higher efficiency. The same content as the foregoing embodiment 1 will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com