Structure of fitting for assembled furniture

A technology for combining furniture and accessories, which is applied in the direction of connecting components, thin-plate connections, mechanical equipment, etc., can solve problems that affect the firmness of the connection between the tread plate and the vertical plate or beam plate, loose connection parts, hidden dangers to the safety of the stairs, etc., to achieve the elimination of safety hazards. Hidden dangers, improvement of construction efficiency, and improvement of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to make it easier for those skilled in the art to understand other features and advantages of the present invention, and achieve more remarkable effects, the present invention will now be described in detail with the accompanying drawings as follows:

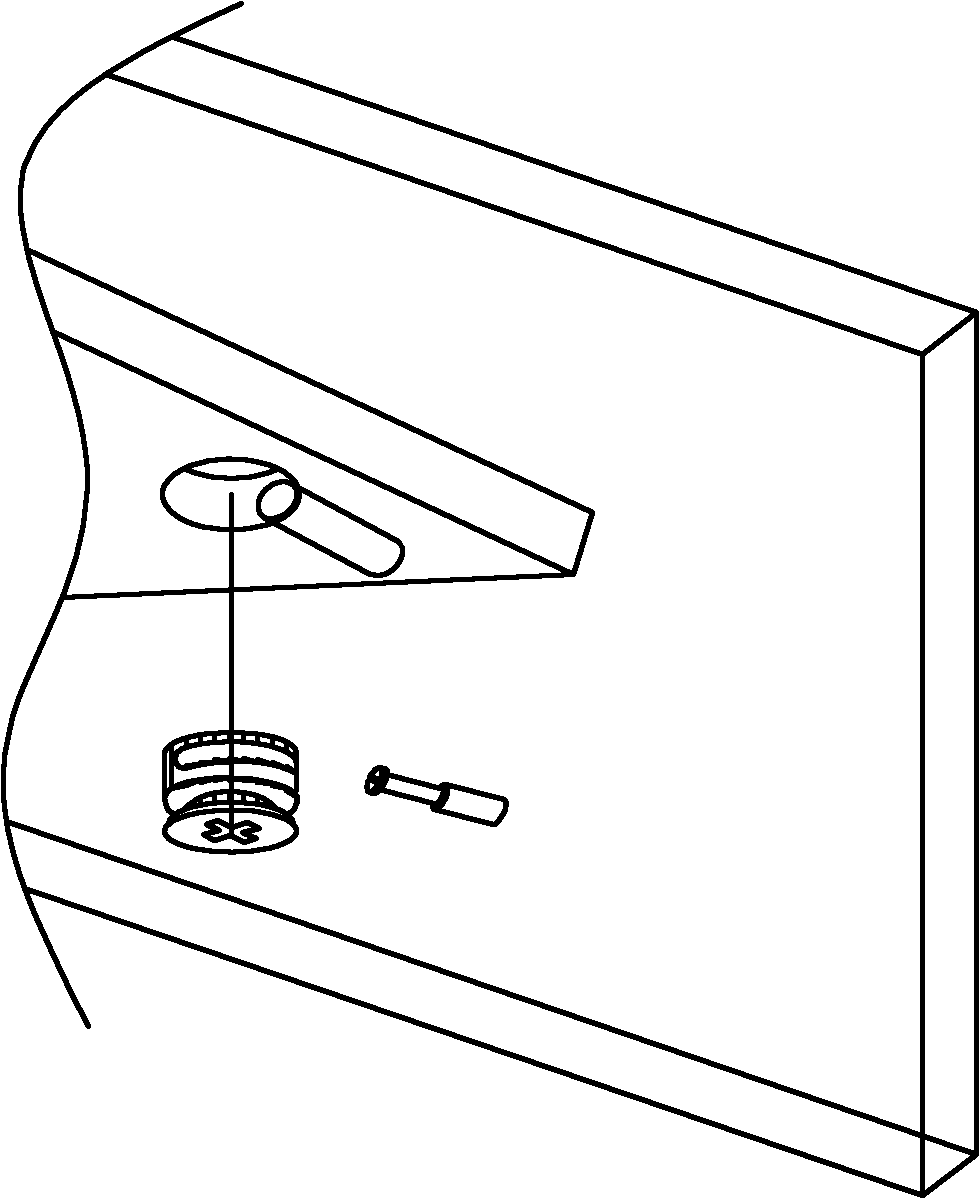

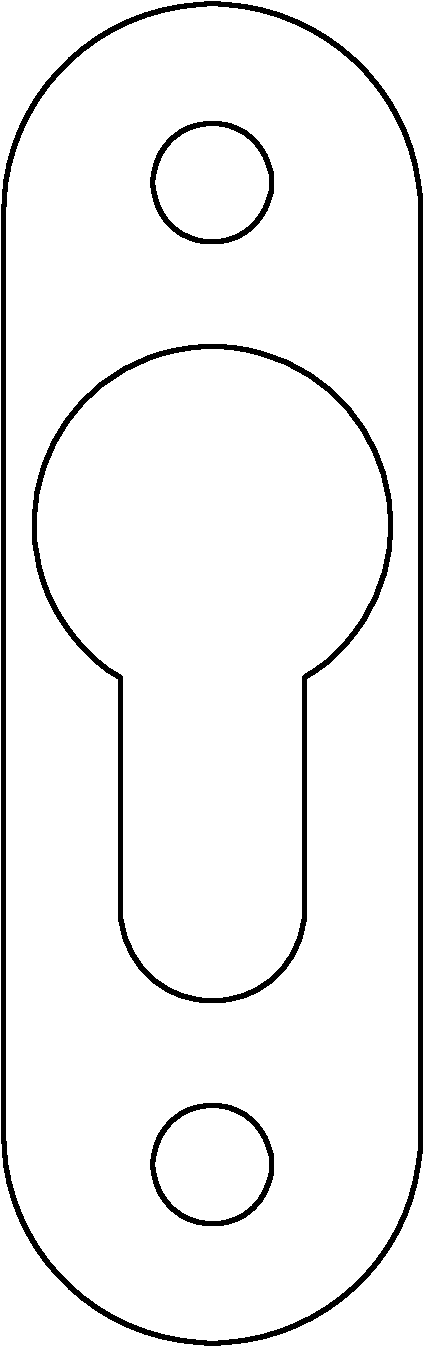

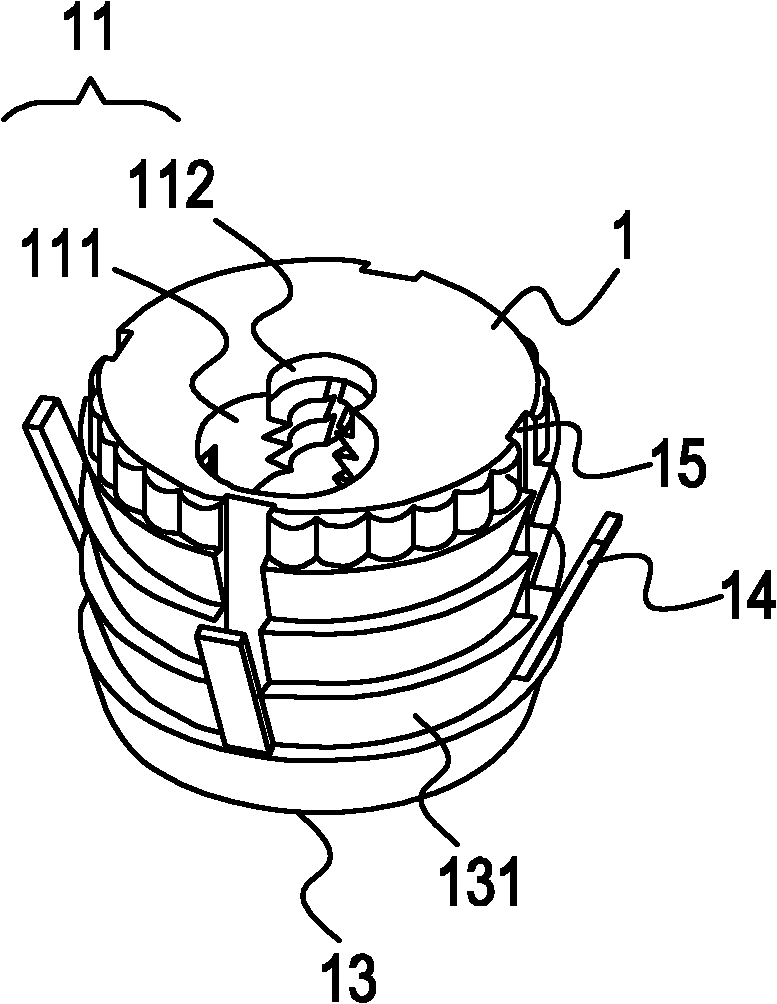

[0071] Please also see image 3 , Figure 4A and Figure 4B , image 3 It is a perspective view of the first implementation of the present invention, Figure 4A , Figure 4B It is a sectional view of the first implementation of the present invention. As shown in the figure, the combined furniture fittings structure of the present invention includes a fitting body 1, and the fitting body 1 is provided with a combination hole 11, which extends vertically from the top surface of the fitting body 1 to the bottom surface, and the combination hole 11 includes an opening groove 111 and a positioning groove 112, and at least one expansion groove 12 is formed inside the combination hole 11, and the groove wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com