Roller bed power system of industrial microwave high temperature roller bed continuous sintering furnace

A power system and sintering kiln technology, which is applied in the field of roller table power system, can solve the problems of poor transmission effect, small floor space and high transmission efficiency, and achieve low equipment investment cost, small floor space and low transmission noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

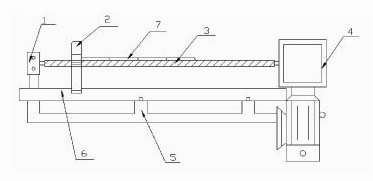

[0019] A roller table power system for an industrial-grade microwave high-temperature roller table continuous sintering kiln, such as figure 1 As shown, the roller table power system includes a variable frequency motor 4, a rectangular screw 3, a pusher 2 and a bearing seat 1, the output end of the variable frequency motor 4 is connected to one end of the rectangular screw 3, and the rectangular screw 3 passes through the pushing The device 2 cooperates with the pusher 2, and the other end of the rectangular screw 3 is connected with the bearing in the bearing seat 1, and the bearing in the bearing seat 1 is a universal bearing. The rectangular screw 3 is provided with a push plate 7 for transporting materials, and the push plate 7 is connected with the pusher 2 . The lower end of the pusher 2 can move along a rail groove 6 . Described guide rail groove 6 lower end is provided with guide rail bracket 5, and the stainless steel that this guide rail bracket adopts is made, can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com