Line filter

A filter and circuit technology, applied in the manufacturing of circuits, inductors, coils, etc., can solve the problems of reducing height, unable to perform correct positioning, unable to fully ensure insulation distance, etc., to achieve the effect of ensuring insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

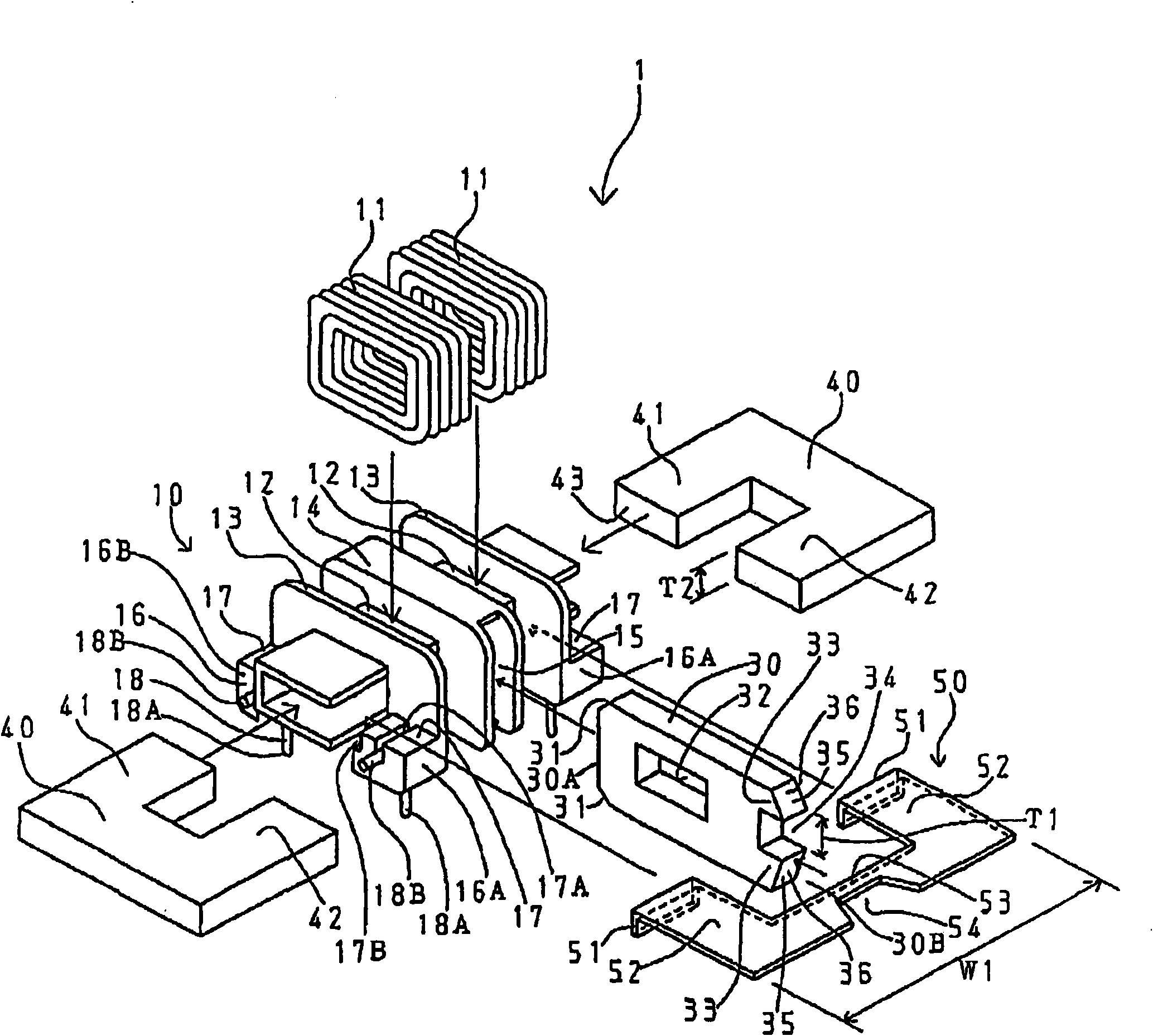

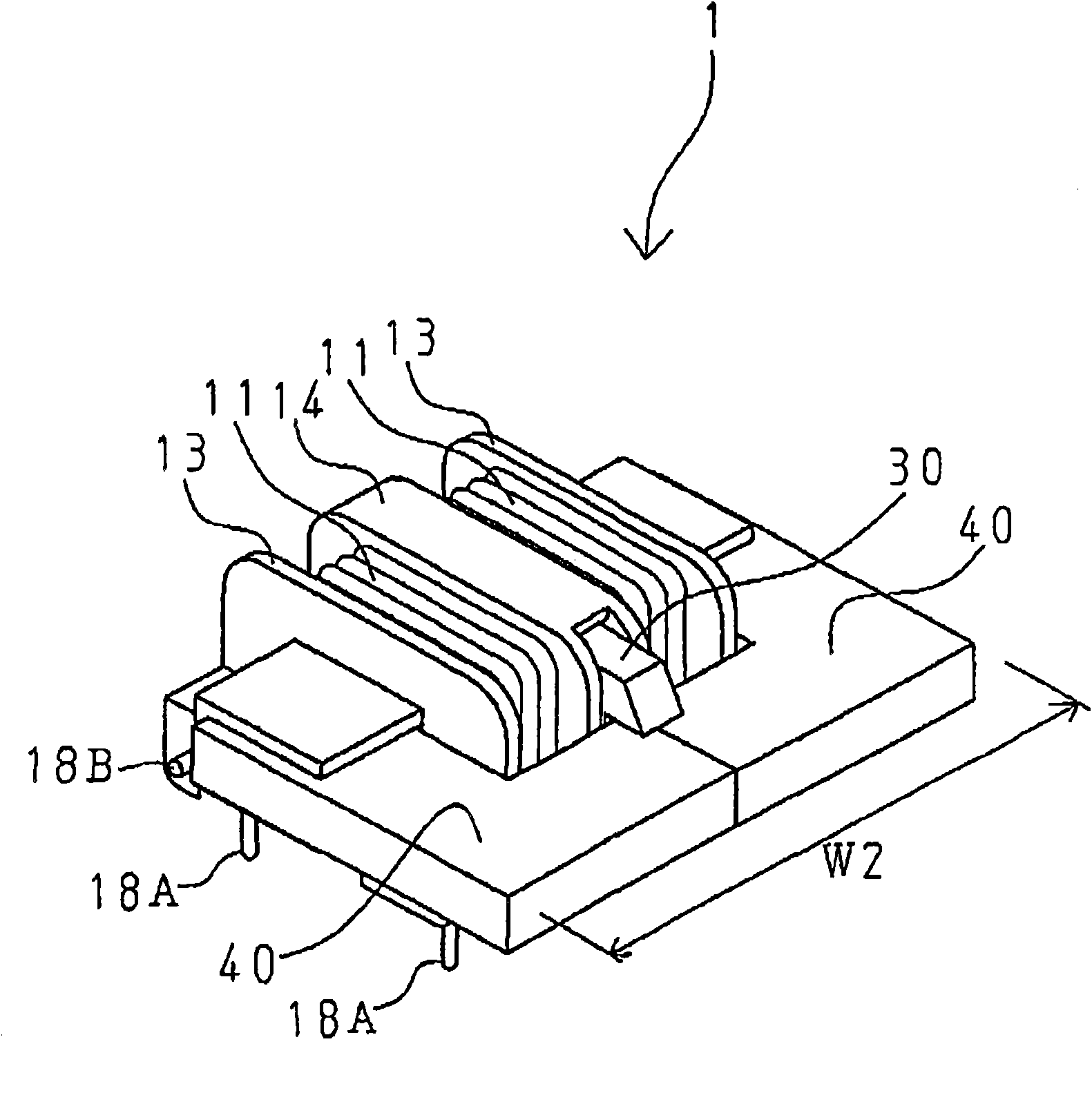

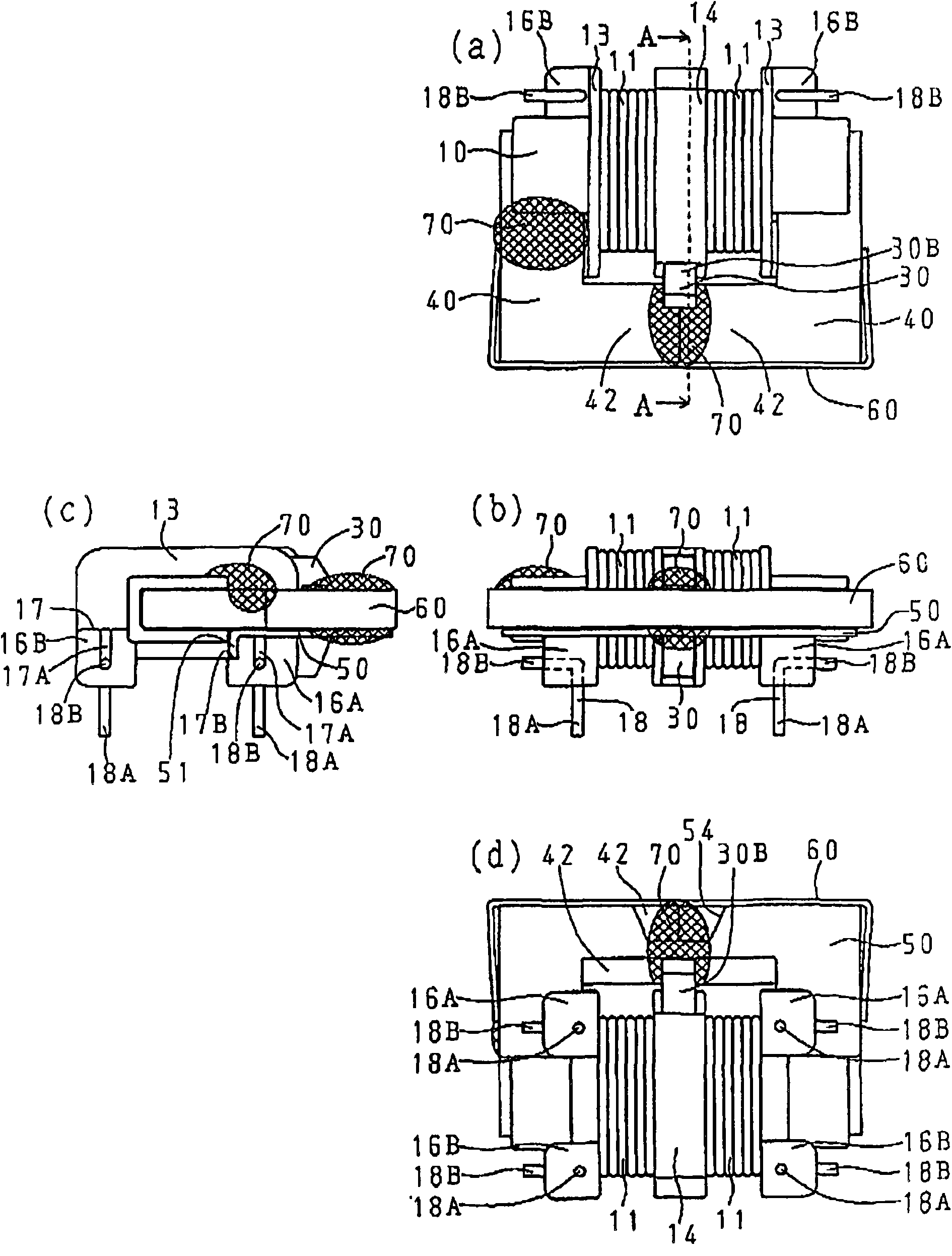

[0029] figure 1 It is an exploded perspective view of main parts of the line filter according to the first embodiment of the present invention. figure 2 yes figure 1 The main part of the line filter in the complete perspective view. image 3 It is a plan view (a), a front view (b), a side view (c), and a bottom view (d) of the completed line filter of the present invention. Figure 4 yes image 3 Sectional view of part A-A of the line filter in . Figure 5 With image 3 A flow diagram of the magnetic flux corresponding to the common-state noise in . Figure 6 With image 3 Flow plot of magnetic flux corresponding to normal noise in .

[0030] exist Figure 1 to Figure 6 Among them, the line filter 1 of this embodiment includes: a terminal bobbin 10 , a common mode core 40 , a normal mode core 30 , a bracket 60 , and a cover 50 .

[0031] The terminal-equipped bobbin 10 is composed of an integral molded product of synthetic resin, and includes: a winding core 12 aro...

no. 2 approach

[0061] Figure 7 It is an exploded perspective view of the line filter 1 according to the second embodiment of the present invention. exist Figure 7 In , the same reference numerals are assigned to the same components as those of the first embodiment, and repeated explanations will be omitted.

[0062] In the second embodiment, the difference from the first embodiment is that although the support portion 53 of the cover 50 is pressed against the front end 37 of the inclined surface 36 of the magnetic leg bottom surface 35 of the substantially A-shaped normal mode magnetic core 30, the A flat surface 44 is provided on the bottom surface 35 of the magnetic foot to which the support portion 53 of the cover 50 is pressed.

[0063] In this way, the above-mentioned effects can be obtained, and the support portion 53 of the cover 50 can face-contact and press-contact the flat surface 44 of the magnetic foot bottom surface 35 and the positioning of the normal mold core 30 can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com