Branched chain ether type anionic surfactant and preparation method thereof

A surfactant and anion technology, applied in the field of branched-chain ether sulfonate anionic surfactant and its preparation, can solve the problems of complicated operation steps, complex synthesis process, harsh reaction conditions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

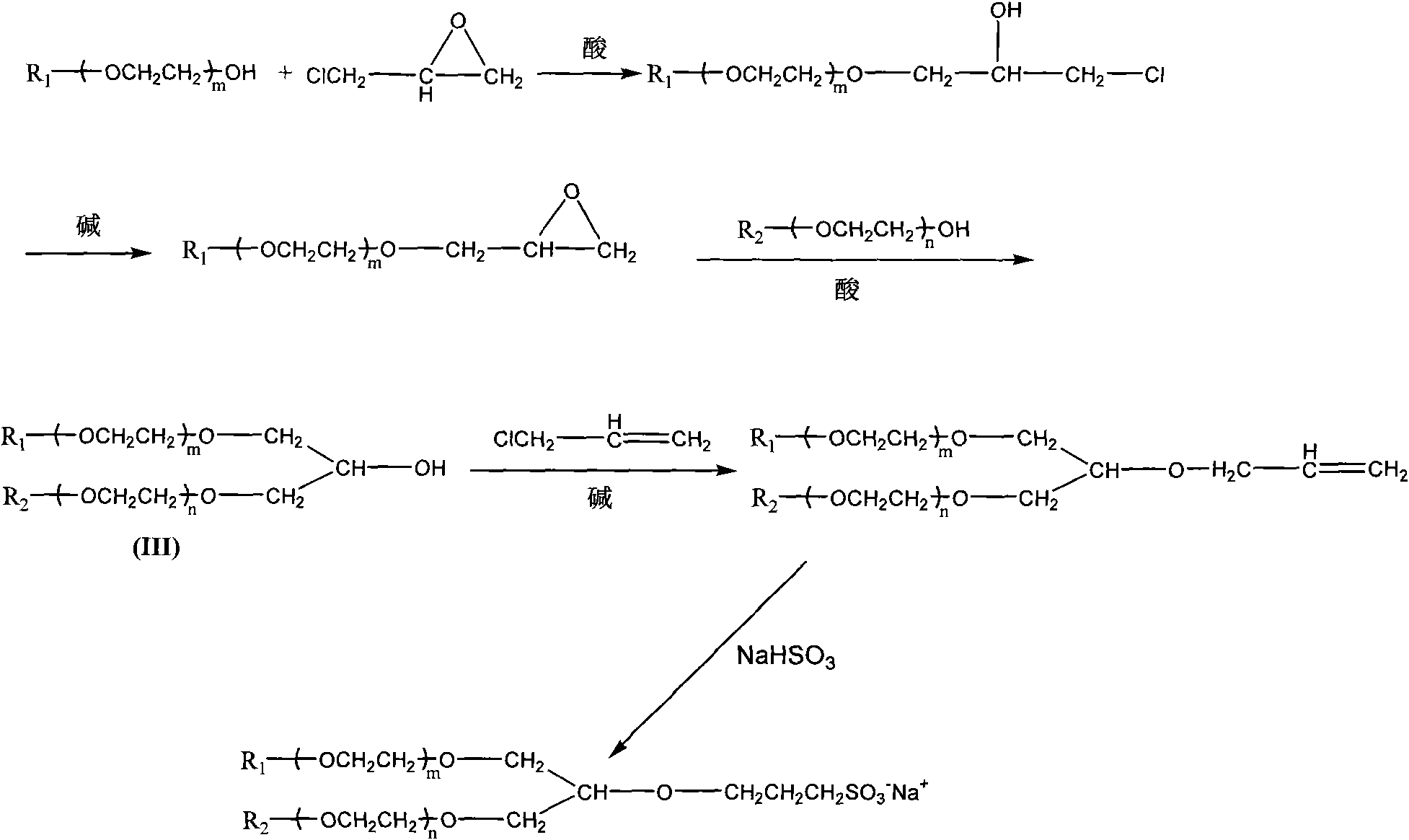

Method used

Image

Examples

Embodiment 1

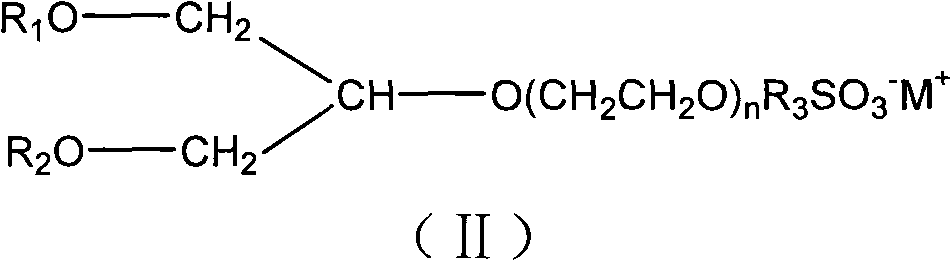

[0076] Synthetic novel surfactant (1) has the following structure:

[0077]

[0078] Step 1: adding polyoxyethylene lauryl alcohol (3) ether to epichlorohydrin to obtain chloroglycerin ether. The reaction temperature is 80°C; the reaction time is 2 hours. with SnCl 4 For the addition reaction catalyst; in molar ratio,

[0079] Lauryl alcohol polyoxyethylene (3) ether: epichlorohydrin: SnCl 4 =1:1:0.006.

[0080] Step 2: Intramolecular cyclization reaction of the obtained chloroglyceryl ether under the action of alkali to obtain glycidyl ether. Reaction temperature is 85 ℃; Reaction time is 4 hours; Molar ratio,

[0081] Chloroglycerin ether: alkali = 1: 1.6;

[0082] The base is NaOH, used as a 30% aqueous solution.

[0083] Step 3: adding the obtained glycidyl ether to isooctyl alcohol polyoxyethylene (3) ether to obtain a two-tailed alcohol intermediate with the structural formula (VI). The reaction temperature was 80°C, and the reaction time was 2 hours.

[0084...

Embodiment 2~9

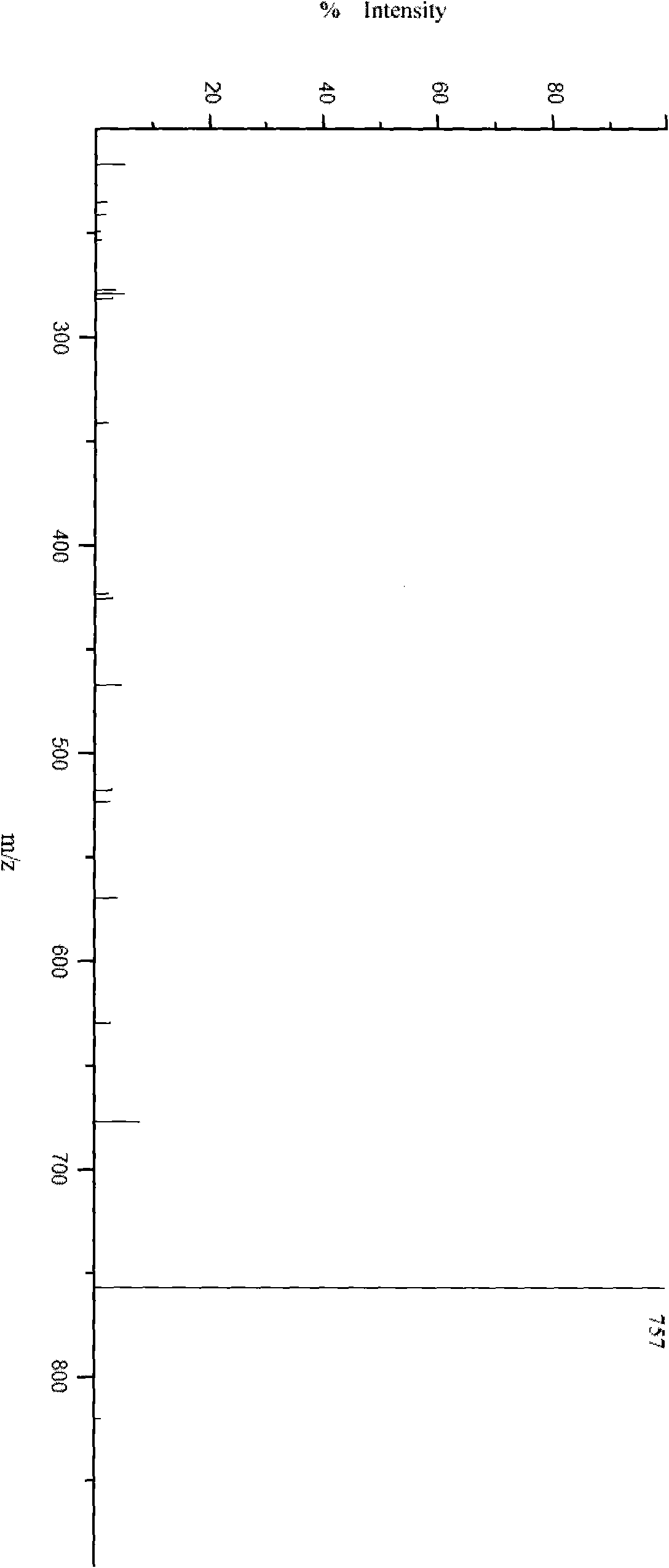

[0097] According to the method of Example 1, different raw materials 1 and 2 were selected as starting materials, and a series of novel surfactants (2)-(9) having the general formula (I) were synthesized. The structures of the synthesized compounds were confirmed by negative ion ESI-MS. Raw material 1, raw material 2 and R in the product structure formula 1 , R 2 , R 3 , m, n, M are shown in Table 1.

[0098] Table 1 branched chain ether type sulfonate anionic surfactant of the present invention

[0099]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap