Rotary swaging machine

A technology of rotary forging machine and machine head, which is applied in forging/pressing/hammering machinery, forging/pressing/hammer device, hammer, etc. It can solve the problems of poor processing technology of parts, small processing range, large vibration and noise, etc. To achieve the effect of reliable working performance, small vibration and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

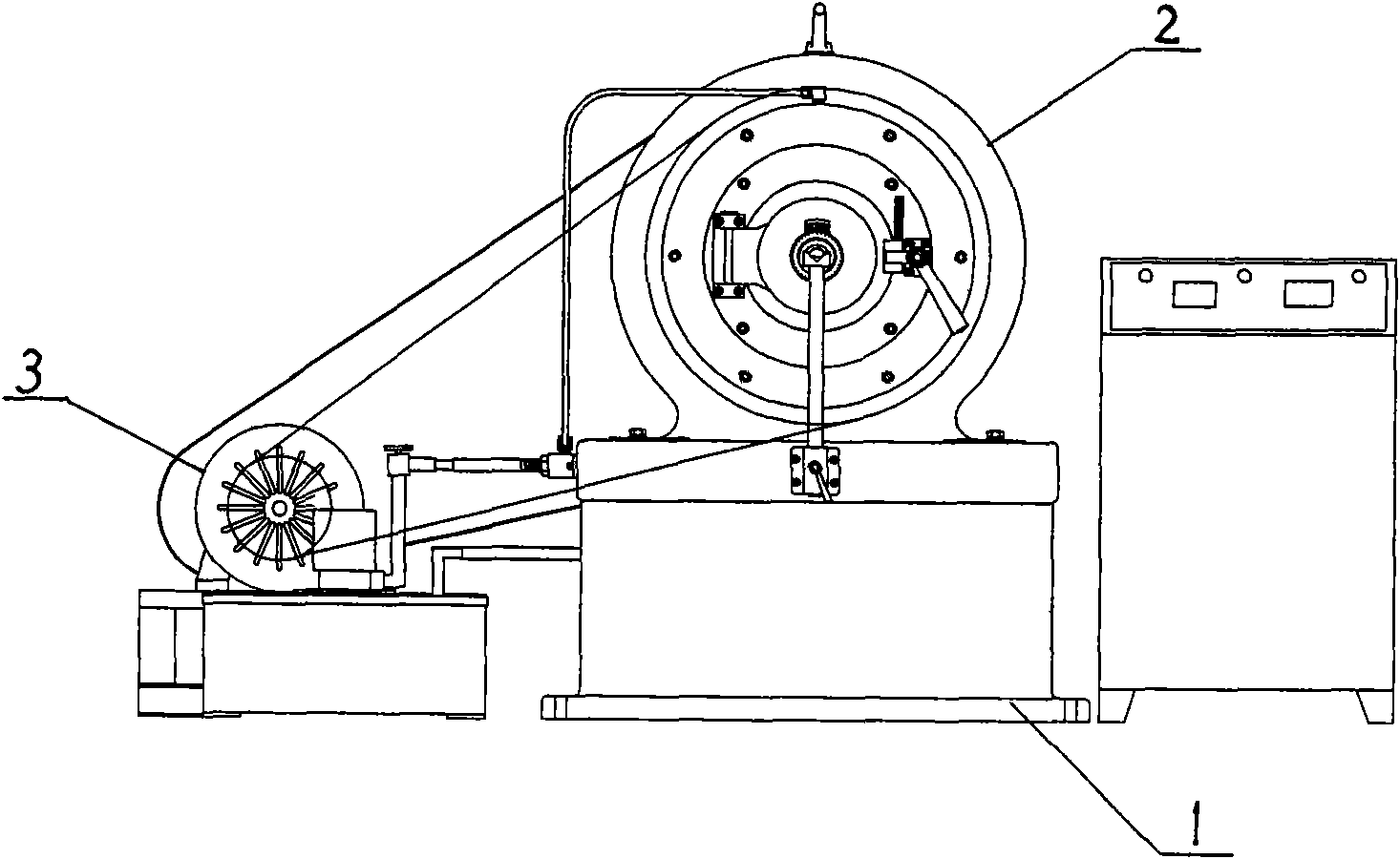

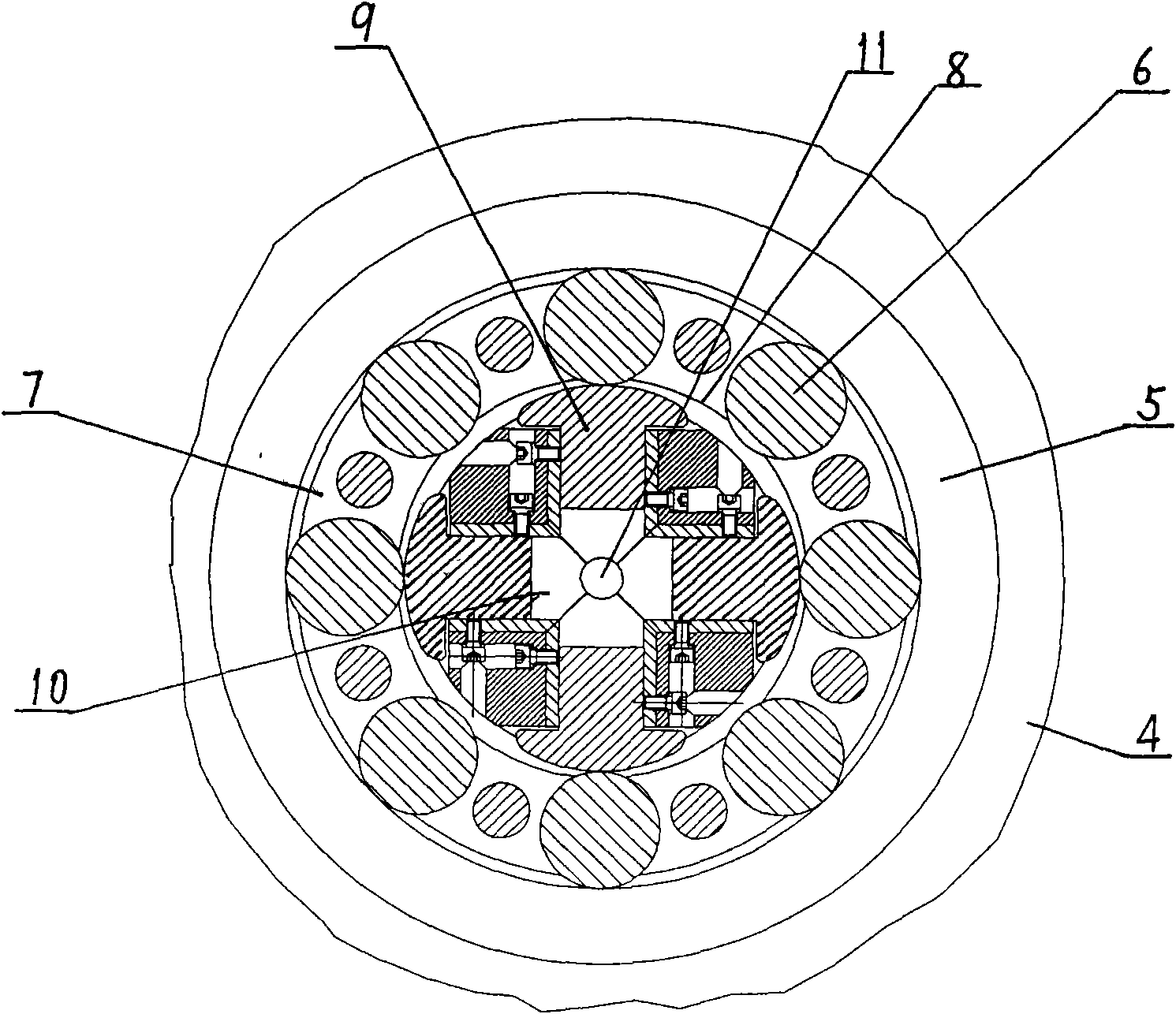

[0010] Such as figure 1 and figure 2 As shown, the present invention includes a machine head 2 arranged on a base 1 and a main motor 3 arranged on one side of the machine head 2. The machine head 2 includes a cylindrical shell 4, and an embedded Ring 5, located at the center of the bezel 5, a separator 7 with a support hole is arranged along the axis, and a roller 6 is installed in the support hole, and a main shaft 8 connected to the main motor 3 in rotation is arranged along the axis of the separator 7 The main shaft 8 is radially provided with a cross chute, and the center of the cross chute is provided with a forging die 10 with a four-lobe mold structure. A forging hammer 9 is arranged in the cross chute, and the forging die 10 has a square cross section.

[0011] A die hole 11 is arranged in the center of the forging die 10 along the length direction, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com