Molten steel deoxidizing and carbureting method and steelmaking method

A technology of molten steel and deoxidizer, which is applied in the fields of deoxidation and carbonization of molten steel and steelmaking, can solve the problems of high energy consumption, uneven composition of molten steel, inability to determine the initial composition, etc., and achieve the effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

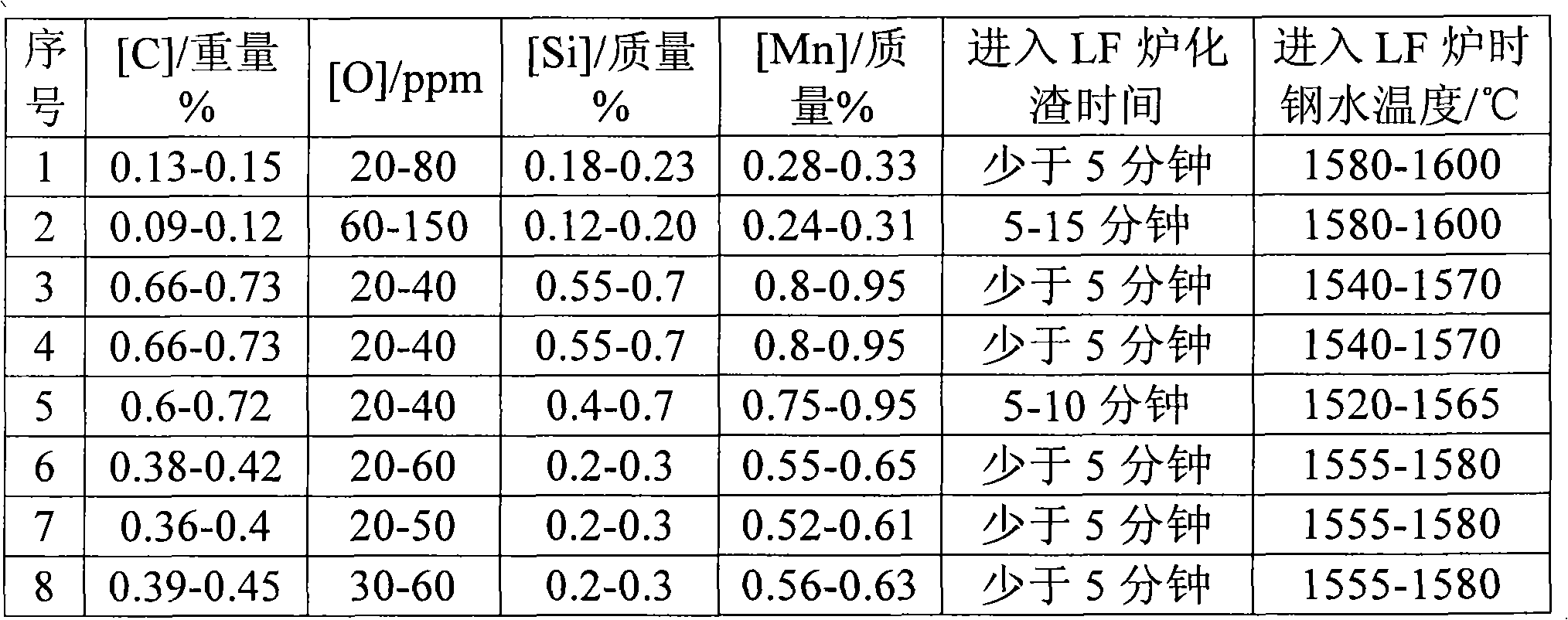

Embodiment 1

[0016] While blowing argon (argon blowing intensity is 3Nm 3 Under the condition of 1660 ℃ of molten steel with a temperature of 1660° C. from the converter into a ladle capable of accommodating 130-145 tons of molten steel, the carbon content during tapping is 0.03-0.15% by weight and the oxygen content is 400 -600ppm; Add 0.4kg / ton of molten steel with a carbon content greater than 90% by weight of a carburizer (a carburizer with a specification of 1-5mm) when tapping so that molten steel enters the ladle; when tapping 1 / 3, add Si 65 % by weight, 14% by weight of Ca, 14% by weight of Ba, 3% by weight of Al, 0.15% by weight of S, 0.04% by weight of P, and the balance is a bulk silicon-calcium-barium alloy with a specification of 10-70mm 2.5kg / ton molten steel ; The ladle is transported to the LF furnace, so that the molten steel enters the LF furnace for refining; the initial composition is detected in the LF furnace, and the initial composition is shown in Table 1, and then ...

Embodiment 2

[0020] Carry out deoxidation, carburization to molten steel according to the method for embodiment 1, difference is that tapping temperature is 1660 ℃, carbon content is 0.03-0.05% by weight, oxygen content 600-1200ppm; / 5 when adding the pre-deoxidation material composition is Si 55% by weight, Ca 16% by weight, Ba 16% by weight, Al 2% by weight, S 0.15% by weight, P 0.03% by weight, and the balance is that the specification of Fe is 10-70mm Block silicon-calcium-barium alloy 0.3kg / ton of molten steel; then add recarburizer 7.5kg / ton of molten steel; when tapping 1 / 2, add silicon-calcium-barium alloy 2.0kg / ton of molten steel with the same composition and specifications as the pre-deoxidized material; The ladle is transported to the LF furnace, so that the molten steel enters the LF furnace for refining; the initial composition is detected in the LF furnace, and the initial composition is shown in Table 1, and then slagging and refining are carried out. Among them, in order t...

Embodiment 3

[0022] Carry out deoxidation, carburization to molten steel according to the method for embodiment 2, difference is that when tapping makes molten steel enter ladle 1 / 4, add pre-deoxidation material composition and be Si 55% by weight, Ca 16% by weight, Ba16% by weight, Al 2% by weight, S 0.15% by weight, P 0.03% by weight, and the balance is 0.8kg / ton molten steel of bulk silicon-calcium-barium alloy with a specification of 10-70mm; the initial composition detected in the LF furnace is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com