Damping abrasion resistant magnesium alloy material and preparation method thereof

A magnesium alloy and damping technology, applied in the field of metal materials, can solve problems such as insufficient wear resistance of materials, and achieve the effects of low production cost, improved wear resistance, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

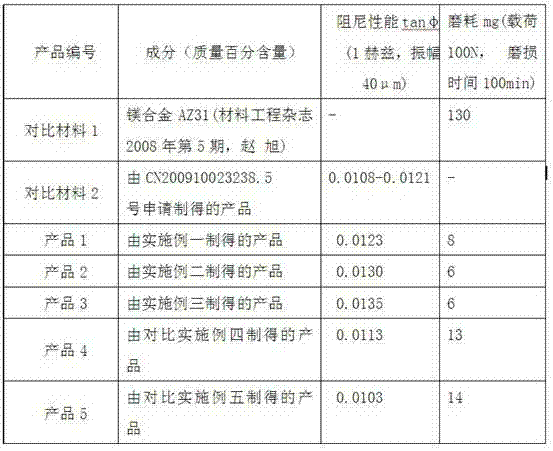

Examples

Embodiment 1

[0029] The weight percentage of the chemical composition of the magnesium alloy matrix: Al is 10%, Sr is 0.2%, Si is 2%, Zr is 0.2%, Fe is 1%, Gd is 0.5%, Ho is 0.01%, and the rest is Mg .

[0030] The weight percentage of the chemical composition of the steel wire is: C is 0.45%, Si is 0.2%, Mn is 0.25%, P<0.02%, S<0.025%; the cross section of the steel wire is rectangular, and the specification is 0.1mm×0.5mm .

[0031] The carbon fiber is T300 with a diameter of 7 microns and an aspect ratio of 100:1.

[0032] The weight ratio of the steel wire and the carbon fiber is 25:1, and the volume percentage of the control steel wire and the carbon fiber is 20% of the material.

[0033] Get steel wire and prepare clean spherical steel wire group by the conventional method of cleaning ball production, the diameter of steel wire group is 10cm, and obtain nickel-plated steel wire group at its surface nickel-plated according to conventional method, the thickness of described nickel-pl...

Embodiment 2

[0038] The weight percentage of the chemical composition of the magnesium alloy matrix: Al is 12%, Sr is 0.5%, Si is 3%, Zr is 0.8%, Fe is 2%, Gd is 1%, Ho is 0.03%, and the rest is Mg .

[0039] The weight percentage of the chemical composition of the steel wire is: C is 0.65%, Si is 0.3%, Mn is 0.35%, P<0.02%, S<0.025%; the cross section of the steel wire is rectangular, and the specification is 0.4mm×1.5mm .

[0040] The carbon fiber is T300 with a diameter of 7 microns and an aspect ratio of 400:1.

[0041] The weight ratio of steel wire and carbon fiber is 30:1, and the volume percentage of the control steel wire and carbon fiber is 40% of the material.

[0042]Get steel wire and prepare clean spherical steel wire group by the conventional method of cleaning ball production, the diameter of steel wire group is 15cm, and obtain nickel-plated steel wire group at its surface nickel-plated according to conventional method, the thickness of described nickel-plated layer is 1...

Embodiment 3

[0045] The weight percentage of the chemical composition of the magnesium alloy matrix: Al is 11%, Sr is 0.3%, Si is 2.5%, Zr is 0.5%, Fe is 1.5%, Gd is 0.7%, Ho is 0.02%, and the rest is Mg .

[0046] The weight percentage of the chemical composition of the steel wire is: C is 0.5%, Si is 0.25%, Mn is 0.3%, P<0.02%, S<0.025%; the cross section of the steel wire is rectangular, and the specification is 0.3mm×0.7mm .

[0047] The carbon fiber is T300 with a diameter of 7 microns and an aspect ratio of 190:1.

[0048] The weight ratio of steel wire and carbon fiber is 27:1, and the volume percentage of the control steel wire and carbon fiber is 35% of the material.

[0049] Get steel wire and prepare clean spherical steel wire group by the conventional method of cleaning ball production, the diameter of steel wire group is 12cm, and obtain nickel-plated steel wire group at its surface nickel-plated according to conventional method, the thickness of described nickel-plated laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com