Freely combined diamond die with fixed bracket

A fixed bracket and combined technology, which is applied in the direction of formwork/formwork/working frame, building components, and on-site preparation of building components, can solve the problems of sudden changes in floor stiffness, unfavorable floor stress, and poor concrete density. Achieve the effect of flexible position adjustment, convenient mandrel layout and concrete compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

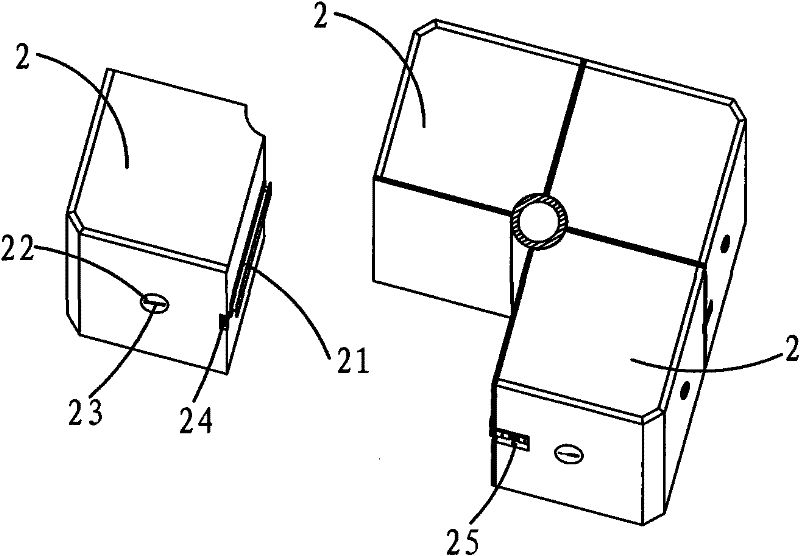

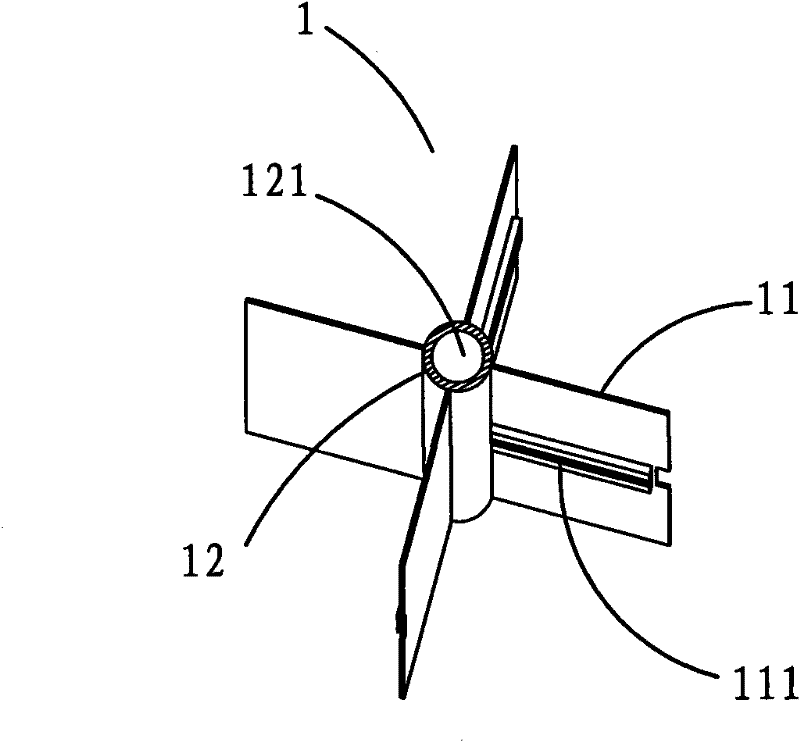

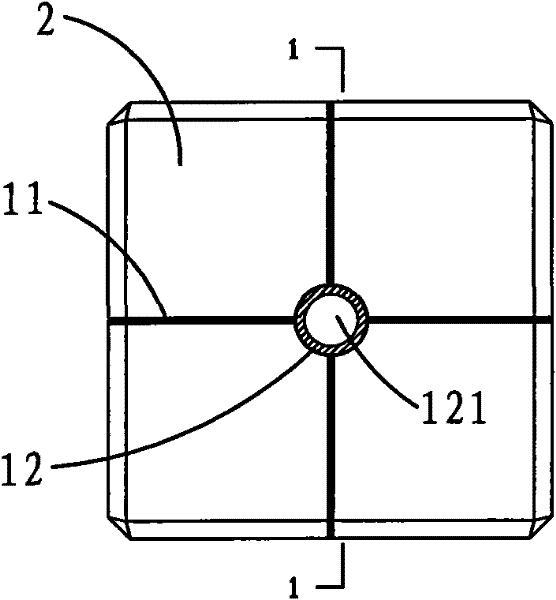

[0038] Please also see Figure 1-6 , is a structural schematic diagram of the combined square core mold of the first embodiment of the present invention, a free combined square core mold with a fixed bracket, including a fixed bracket 1 and four small square molds 2, and the fixed bracket 1 includes a cylinder Shaft 12 and four high-strength blades 11, the cylindrical shaft 12 of described fixed support 1 is hollow shaft (as figure 2 shown in 121). The blades 11 are uniformly fixed on the side wall of the cylinder shaft 12 perpendicular to each other, and a sliding track 111 is respectively provided on the side of each blade 11 along the clockwise (or counterclockwise) direction. The side wall of square small mold 2 is also provided with slide rail 21, and the slide rail 111 of described fixed support 1 and the slide rail 21 on the side wall of square small mold 2 match, and square small mold 2 passes slide rail 21 and The sliding track 111 is matched and installed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com