Patents

Literature

56results about How to "Easy to meet design requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

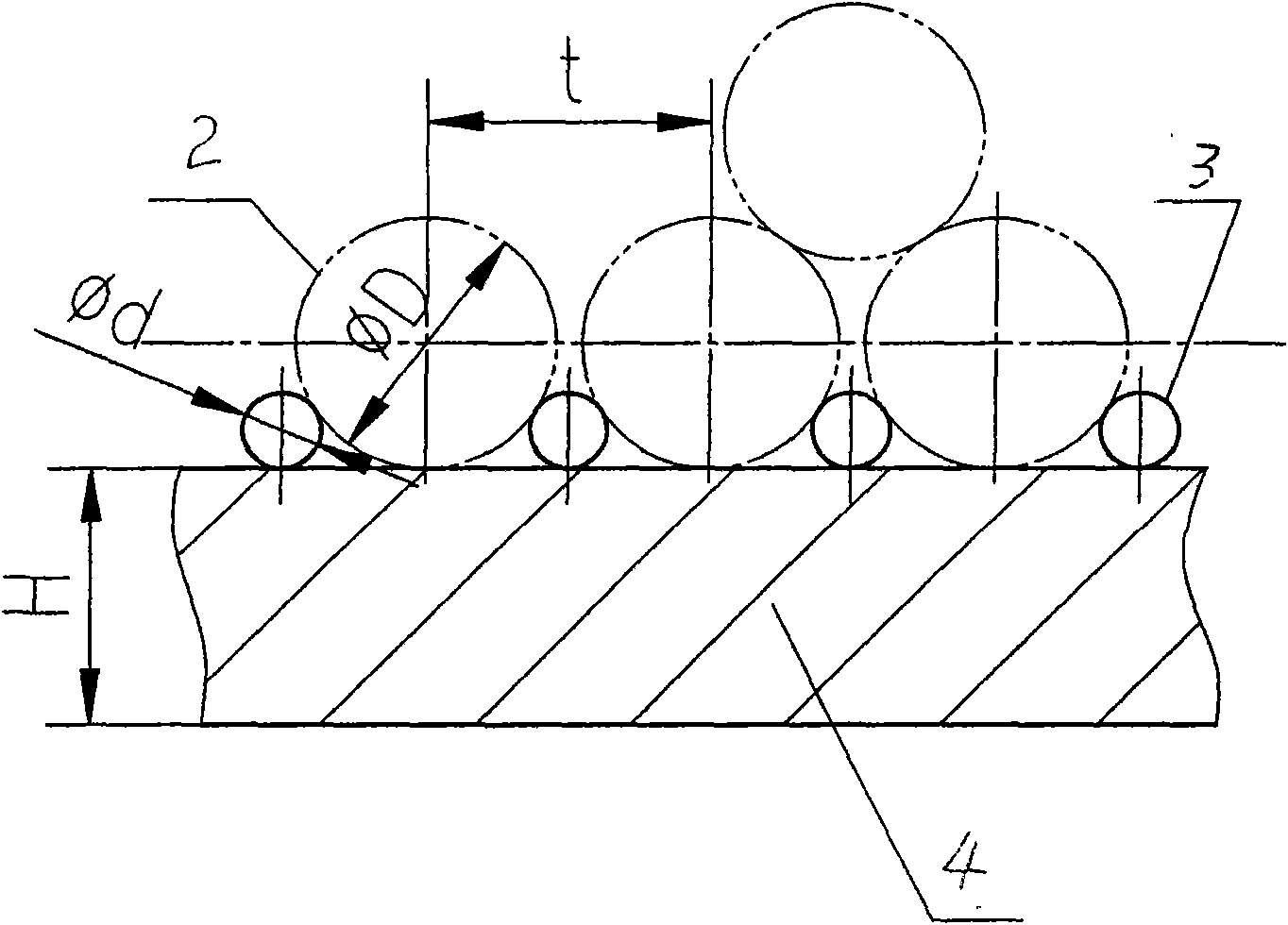

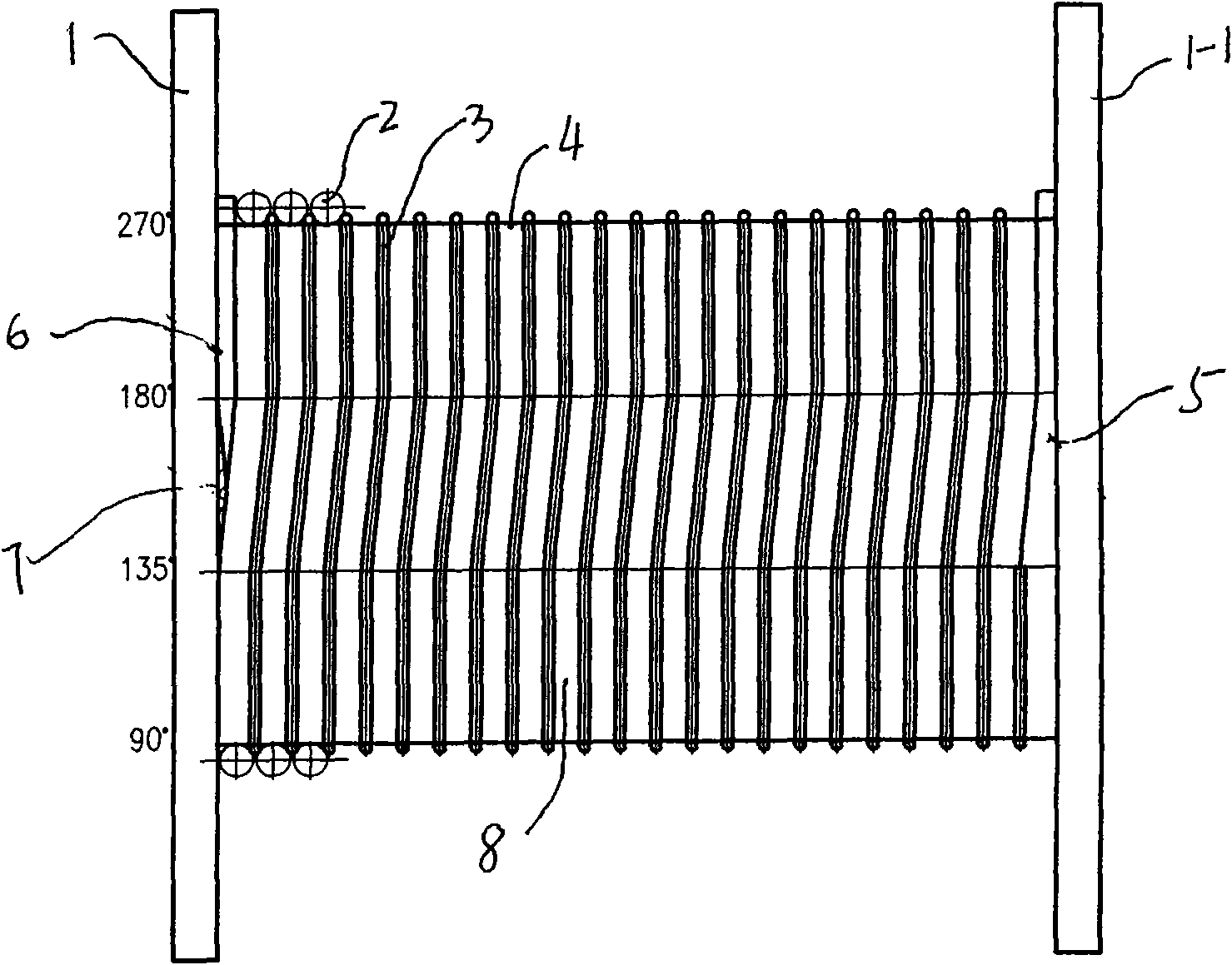

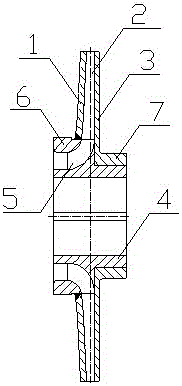

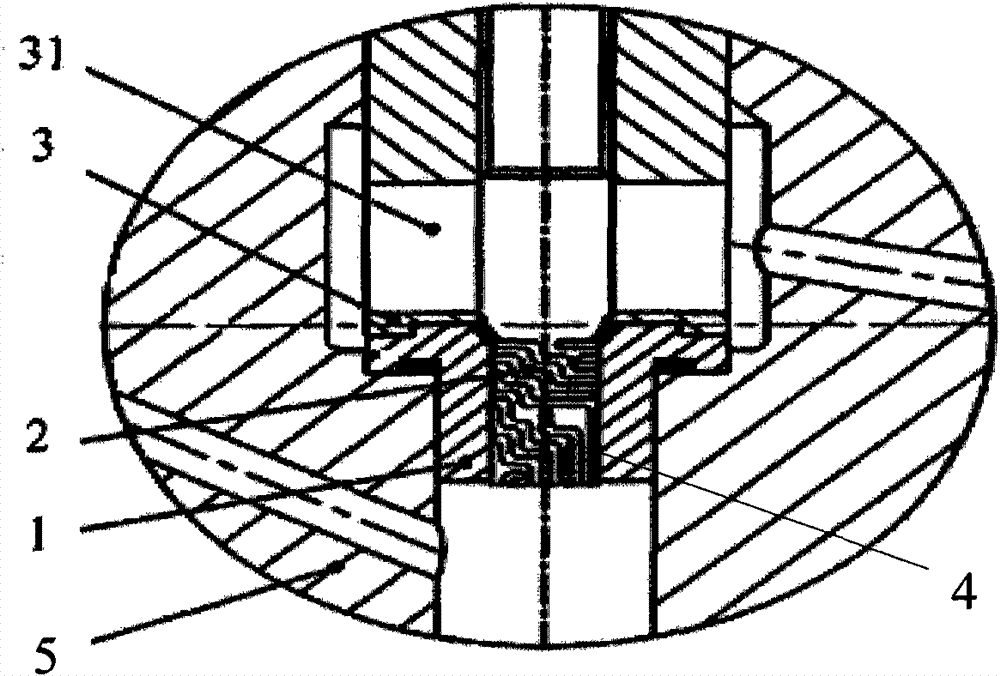

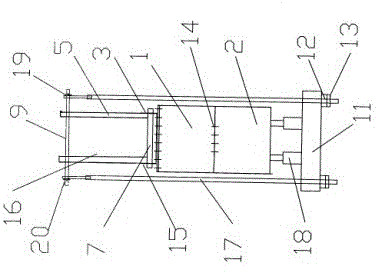

Drum with fold line grooves

A drum with fold line grooves is characterized in that: the drum comprises a smooth drum substrate (4), a left baffle (1) and a right baffle (1-1) which are respectively fixedly connected on a left end and a right end of the drum substrate, and fold line grooves (8) composed of a cylinder material (3) winding on surface of the drum substrate by fixed connection; a gradually narrowing rope supporting boss (6) is arranged at a rope introducing end of the broken line grooves, and a gradually narrowing rope climbing platform (5) is arranged at a tail end of the broken line grooves; a fold back boss (7) is respectively arranged at narrow ends of the rope supporting boss and the rope climbing platform by closely fitting the left baffle and the right baffle; and the fold back boss is vertically arranged, perpendicular to a central axis of the drum substrate, has a cross section of a isosceles triangle structure, and has a plane containing bottom edges which is fixedly connected with lateral facade of the baffles.

Owner:KERUN ELECTRO MECHANICAL ENG

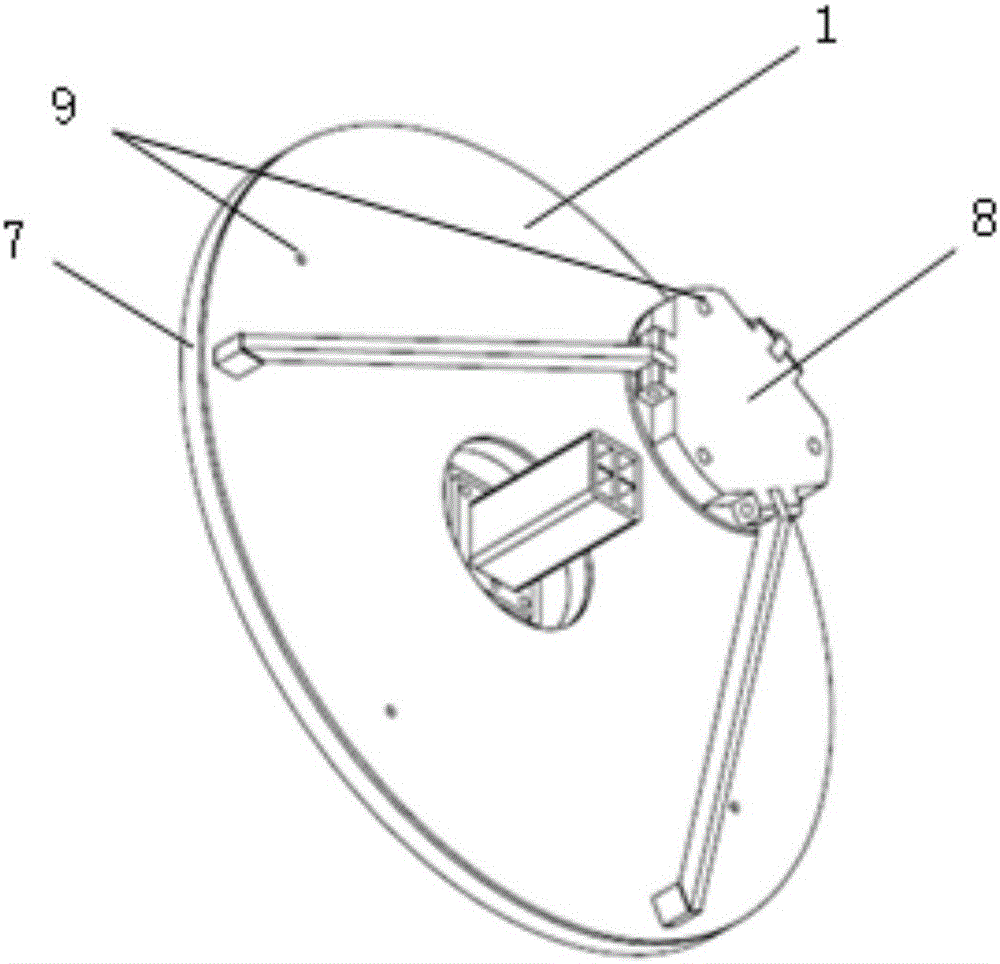

Compact type millimeter-wave monopulse antenna

InactiveCN106159462AReduce volumeReduce weightWaveguide hornsAntenna arraysMillimetre waveMonopulse antennas

The invention discloses a compact type millimeter-wave monopulse antenna and belongs to the technical field of antennas. The compact-type millimeter-wave mmonopulse antenna comprises a feed source, a main reflecting surface, an auxiliary reflecting surface, a supporting structure and a sum-difference network. Both the main reflecting surface and the auxiliary reflecting surface adopt plane reflection array antennas, and the sum-difference network is of a plane structure. Compared with a traditional monopulse antenna, the compact type millimeter-wave monopulse antenna has the advantages of small size, light weight and proneness to connection with other integrated high-frequency components.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Forming method of resin matrix composite with double layers of foam sandwich structures

The invention discloses a forming method of a resin matrix composite with double layers of foam sandwich structures, the entire forming preparation of the resin matrix composite with double layers of foam sandwich structures is realized by adopting a liquid forming method, the forming method comprises the following steps: on a mold which can heat, employing a step-by-step dipping technology, dipping a lower-layer pre-formed body in a pre-formed body of the double layers of sandwich structures in a Z direction by using a resin film infusion method, and then guiding fluid resin by using a vacuum infusion molding process to dip upper-layer pre-formed body and a middle layer pre-formed body in the pre-formed body of the double layers of sandwich structures; after dipping, carrying out co-curing forming on the upper, middle and lower layers of pre-formed bodies and two foam sandwiches clamped between the upper, middle and lower layers of pre-formed bodies, so as to obtain the resin matrix composite with double layers of foam sandwich structures, wherein the upper, middle and lower layers of pre-formed bodies and the two foam sandwiches are thoroughly dipped by resin. The forming method has the advantages of simplicity in operation, environment protection, low cost, high functionality and the like, and is especially suitable for the forming preparation of a large-size composite material component.

Owner:NAT UNIV OF DEFENSE TECH

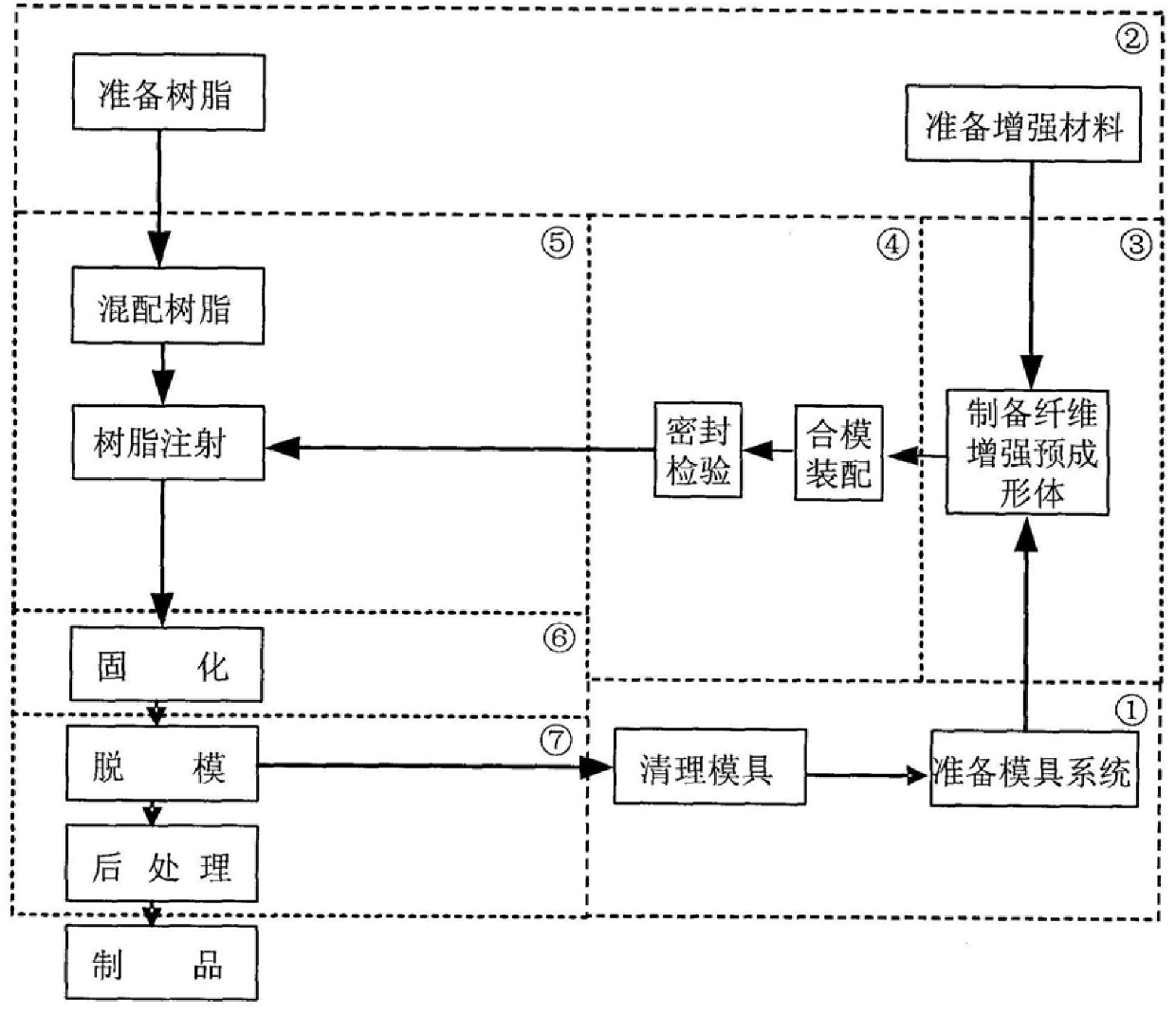

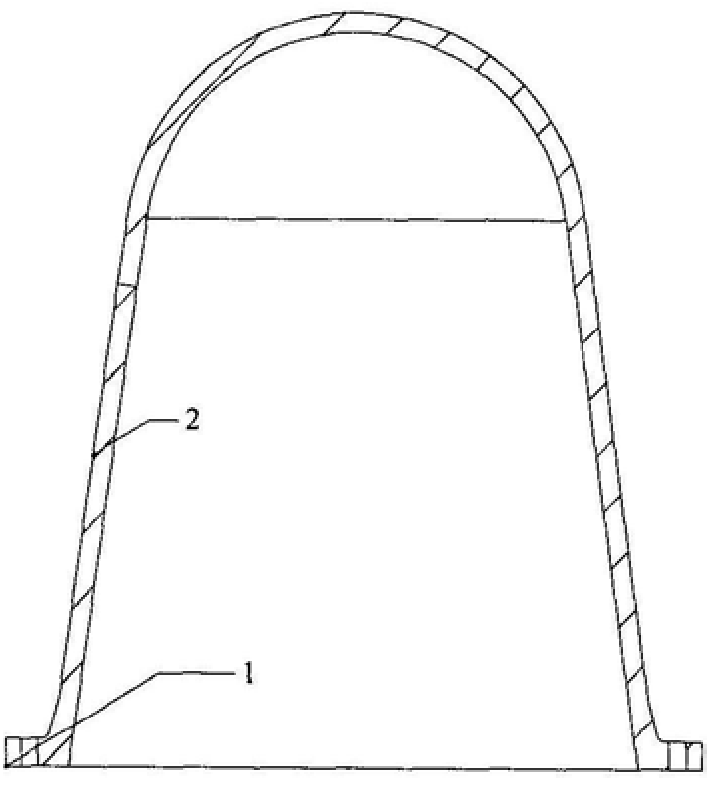

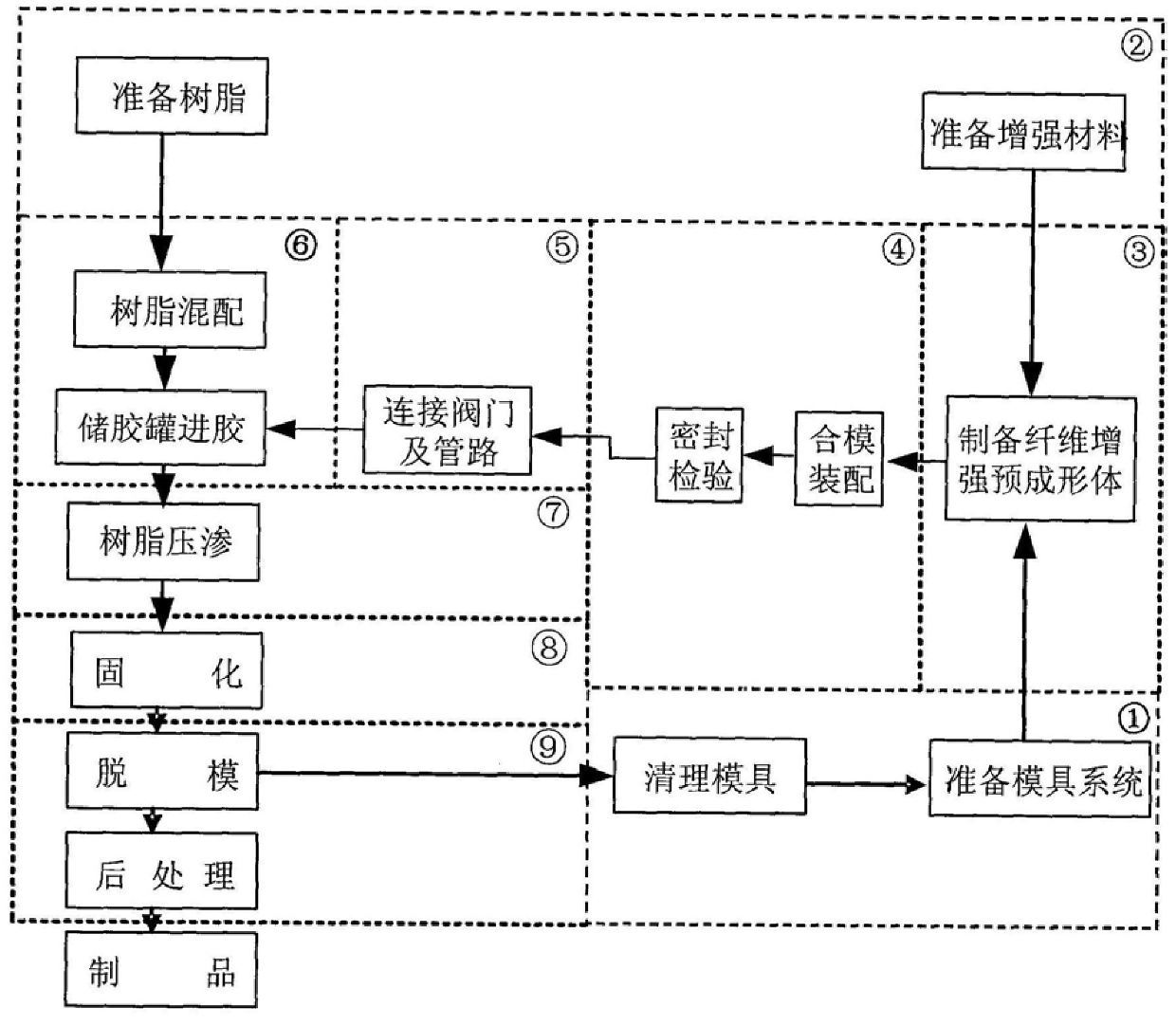

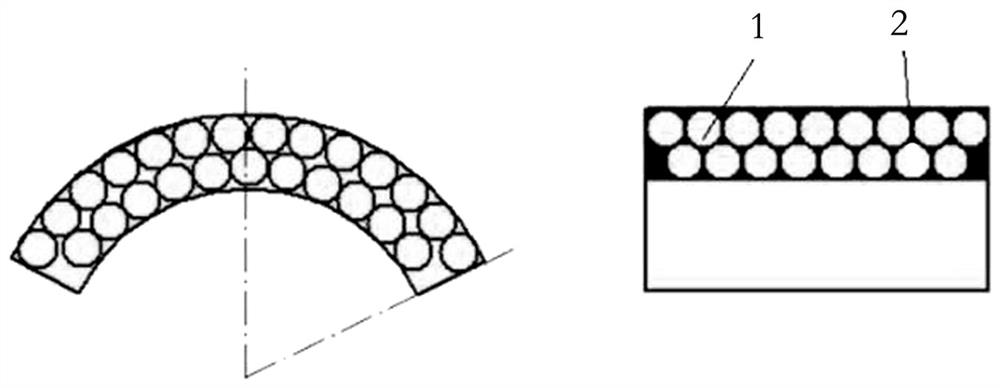

Pressure Infiltration Forming Method of Latent Composite Radome

InactiveCN106507737BSimple and fast operationLow costRadiating element housingsThick wallAtmospheric pressure

The invention discloses a piezo-infiltration molding method for latent composite material radome. The technical problem to be solved is to provide a low-cost overall preparation method for composite material radome, so that the prepared composite material radome has strict dimensions and wall thickness. Uniform, smooth inner and outer surfaces, excellent dielectric properties, and high overall load-bearing performance. The technical solution is to prepare the mold and materials first, then prepare the fiber-reinforced preform, close the mold and seal it, then connect the valve and pipeline, carry out resin mixing, glue storage tank, and then carry out resin pressure infiltration, including normal pressure impregnation. Infiltration and pressure infiltration, and finally curing and demoulding and post-treatment. The preparation of the composite material radome by the present invention is easy to operate and low in cost; it can flexibly adjust the pressurization speed of the resin glue liquid to the mold cavity, and the adjustment range is large, which is especially beneficial to the slow impregnation and integral molding of the composite material radome with a thick-walled structure. .

Owner:NAT UNIV OF DEFENSE TECH +1

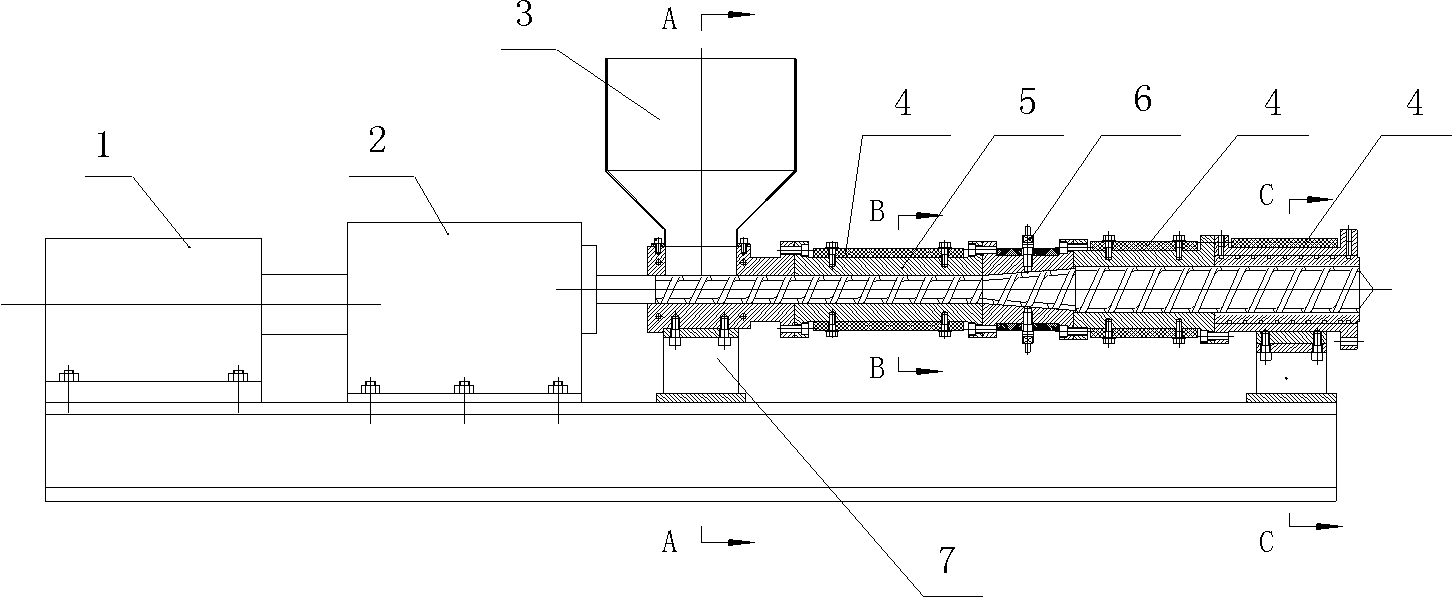

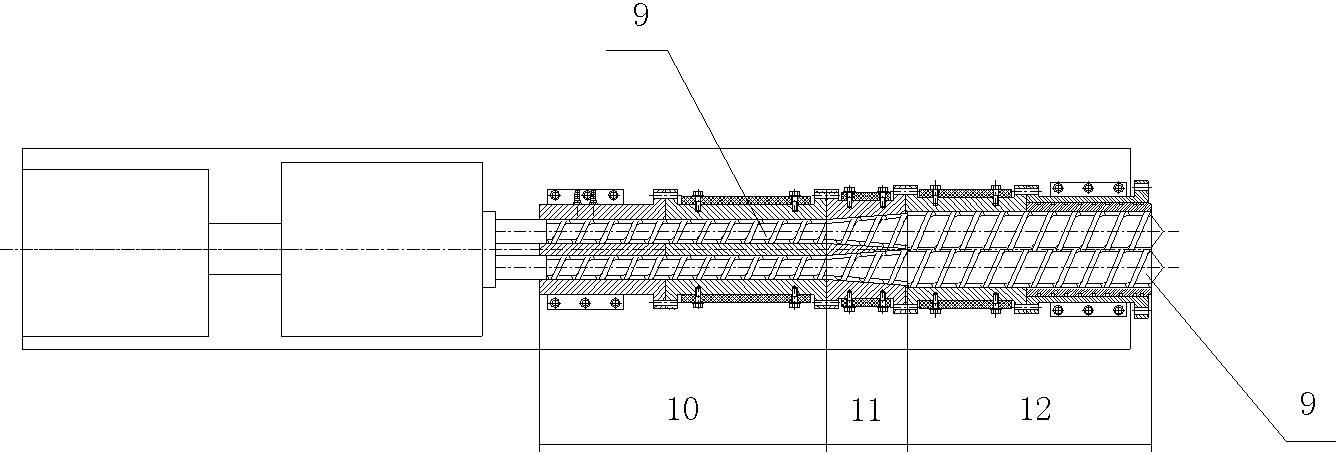

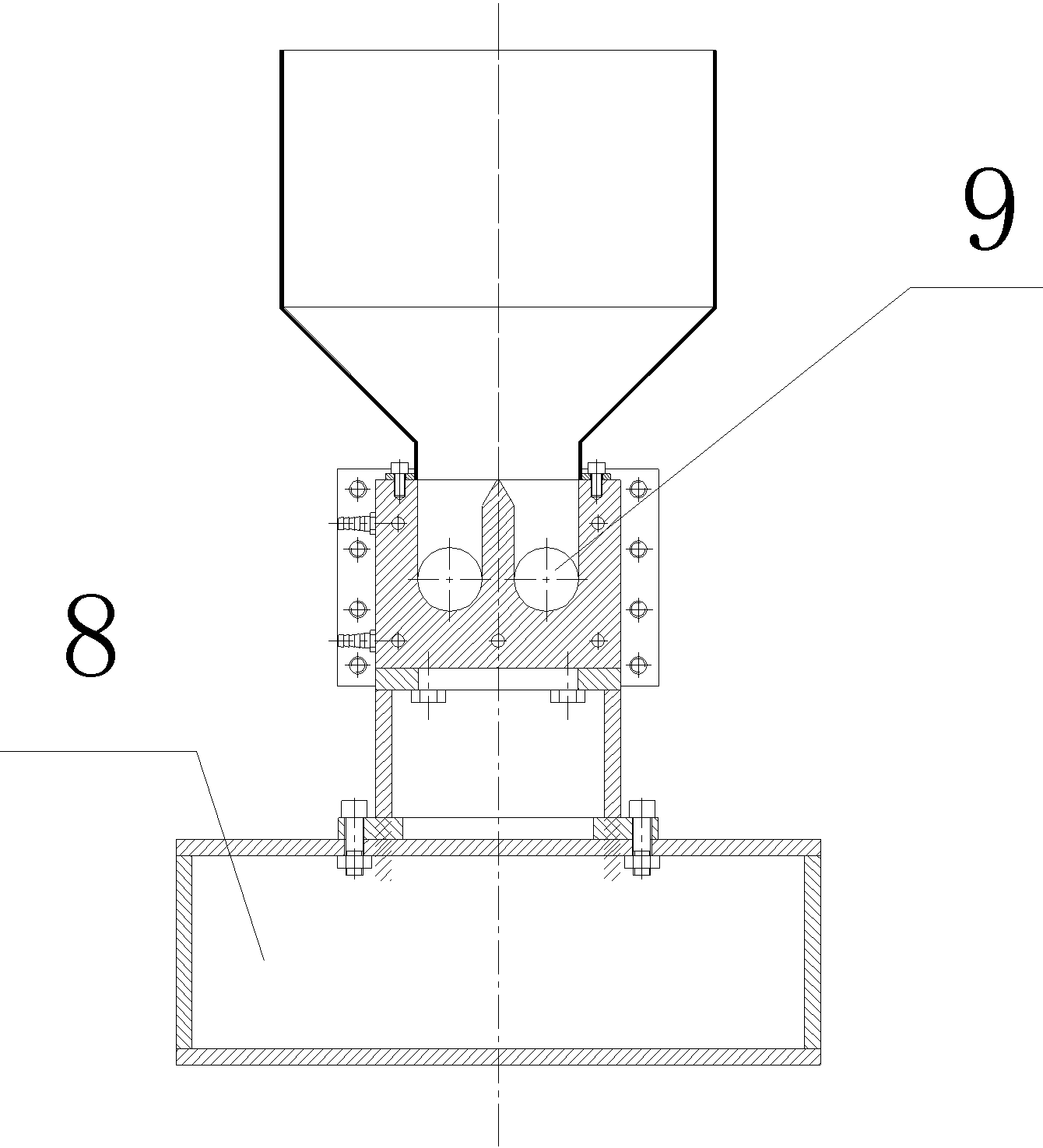

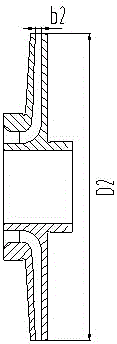

Double-screw extruder

The invention discloses a double-screw extruder which comprises an extruder barrel, two screw units, an independent section and a filling section, wherein two screw units are positioned in the extruder barrel; a screw unit section in one screw unit is meshed with that in the other screw unit to form a meshed section; a discharging hole is formed in the tail end of the meshed section; two independently communicated flow channels are formed in the extruder barrel; the independent section, the filling section and the meshed section are arranged in sequence along the conveying directions of the screw units; both screw units of each of the independent section and the filling section are in non-meshed states and are positioned in the flow channels respectively; heaters are arranged on the whole section of the extruder barrel; a filler is arranged on the filling section. According to the double-screw extruder, the independent section and the filling section are equivalently two independent single screws; molten materials in the screw grooves of the screws have relatively good sealing effects, so that the loss of added gas and supercritical fluid is avoided; the meshed section has a relatively good dispersive mixing effect on the materials, so that the polymer melt foaming is facilitated.

Owner:重庆市南川区利华塑料制品有限责任公司

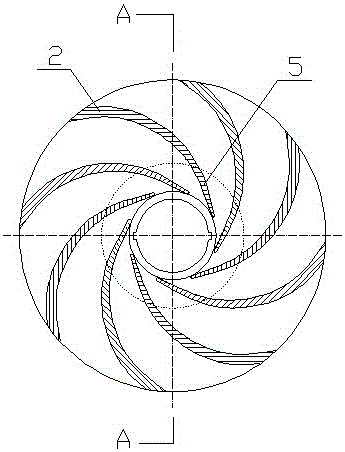

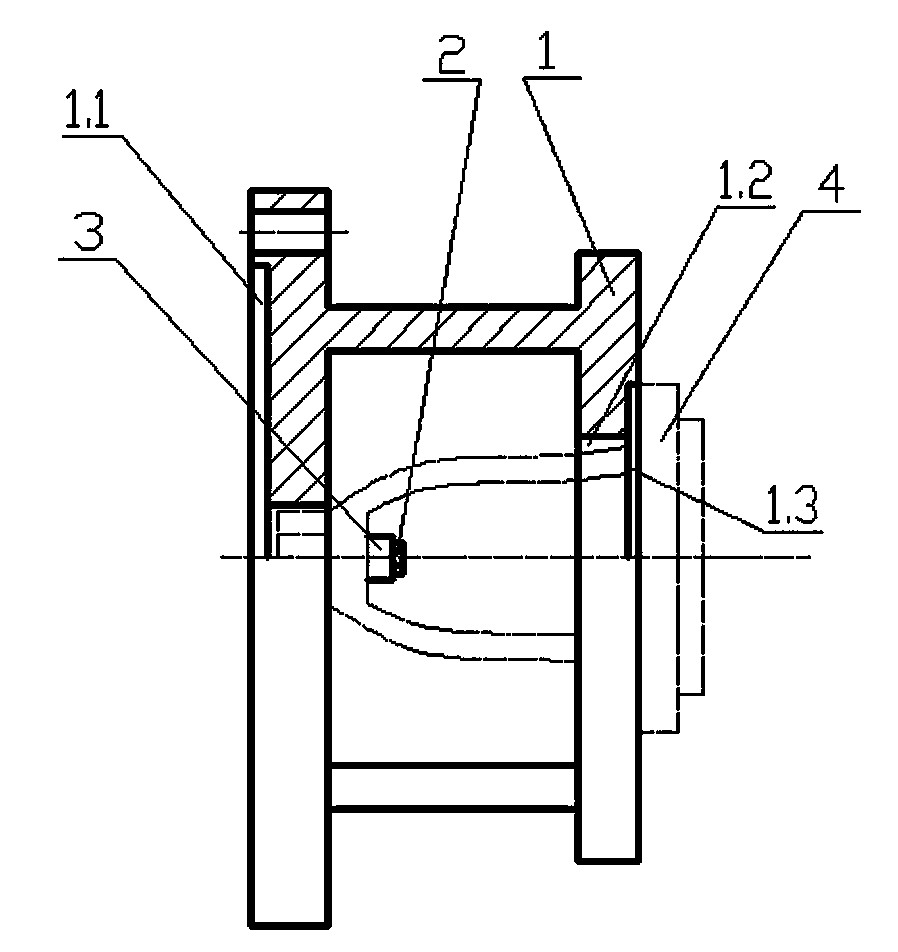

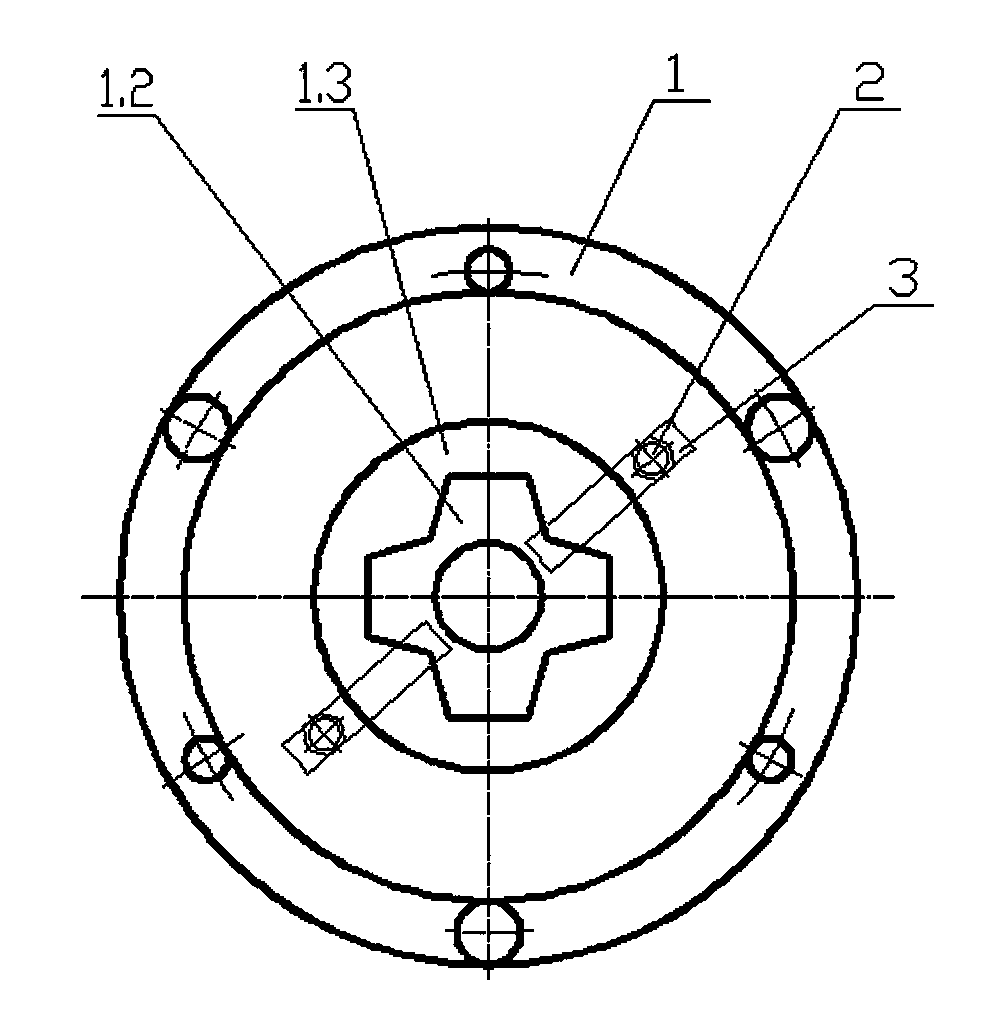

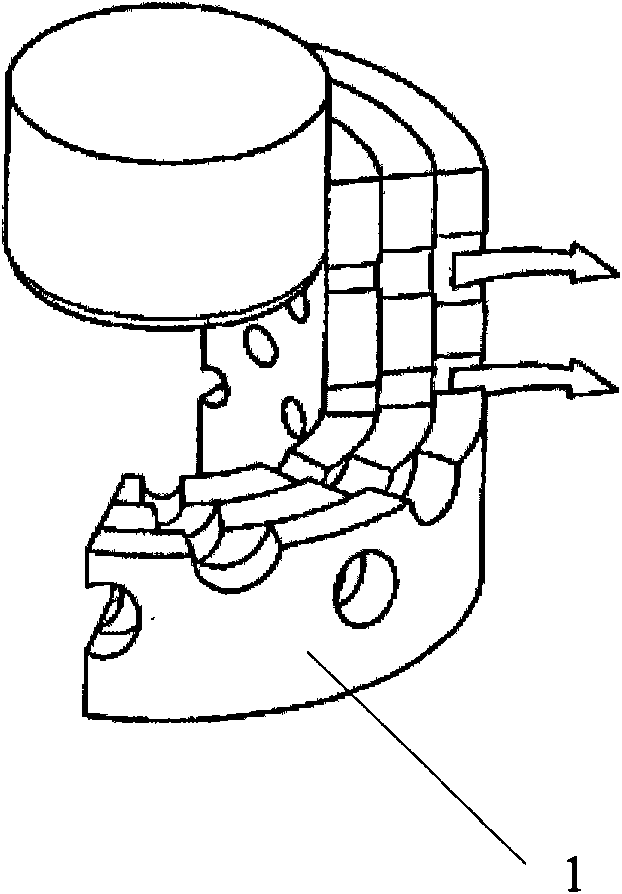

Low-specific-speed impeller structure and machining method thereof

The invention discloses a low-specific-speed impeller structure and a machining method thereof. The structure comprises an impeller body part and an impeller root part; the impeller body part includes a front cover plate, a blade body part and a back cover plate; the impeller root part includes a hub, a blade root part and a sealing ring part; the middle part of the back cover plate is downwards projected to form a sleeve; the back cover plate coats the back part of the hub through the sleeve; the front cover plate coats the sealing ring part; an annular welding line is formed between the front cover plate and the sealing ring part; and the front cover plate and the sealing ring part are tightly welded through the annular welding line. The machining method comprises the following steps: 1) the impeller body part and the impeller root part are respectively cast; 2) the impeller body part coats the impeller root part from the back end of the impeller root part; and the front cover plate coats the sealing ring part; and 3) the annular welding line between the front cover plate and the sealing ring part is tightly welded. The structure is low in machining difficulty, high in machining precision and better in total quality, improves the machining yield, is high in impeller stability, and can effectively improve the guide efficiency.

Owner:重庆水泵厂有限责任公司

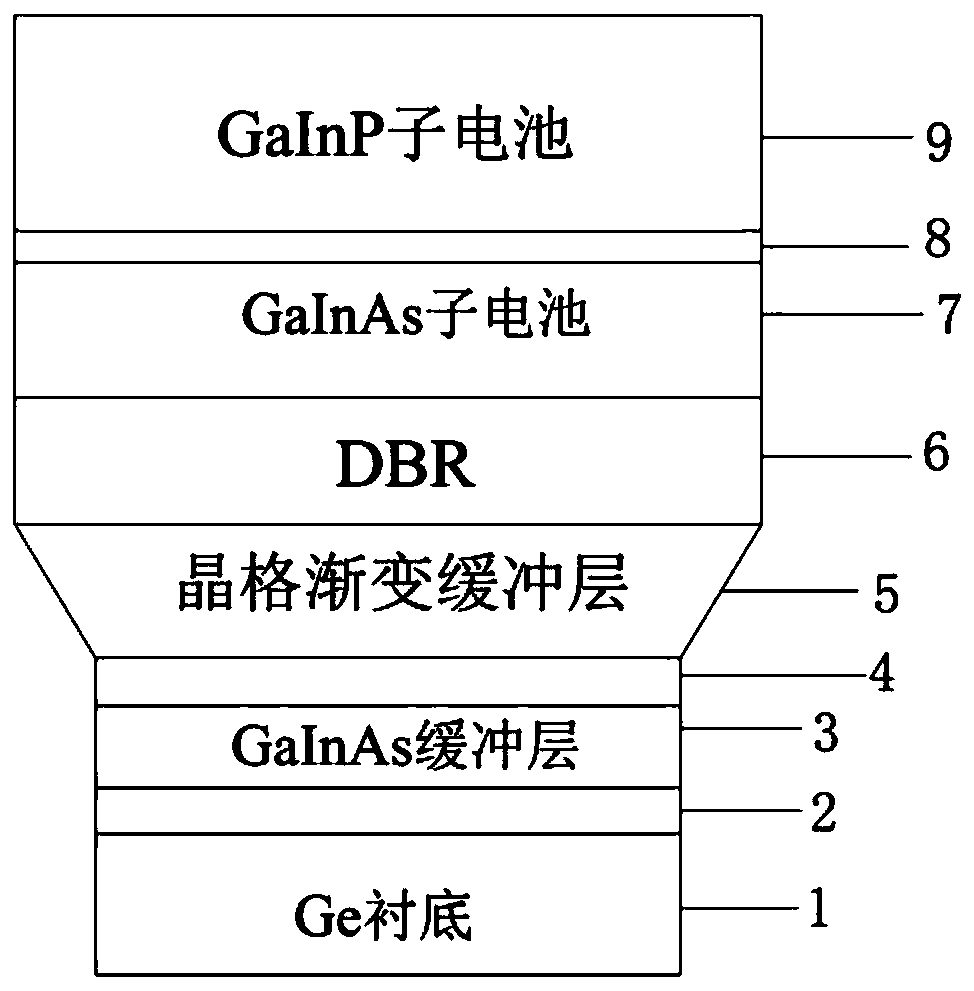

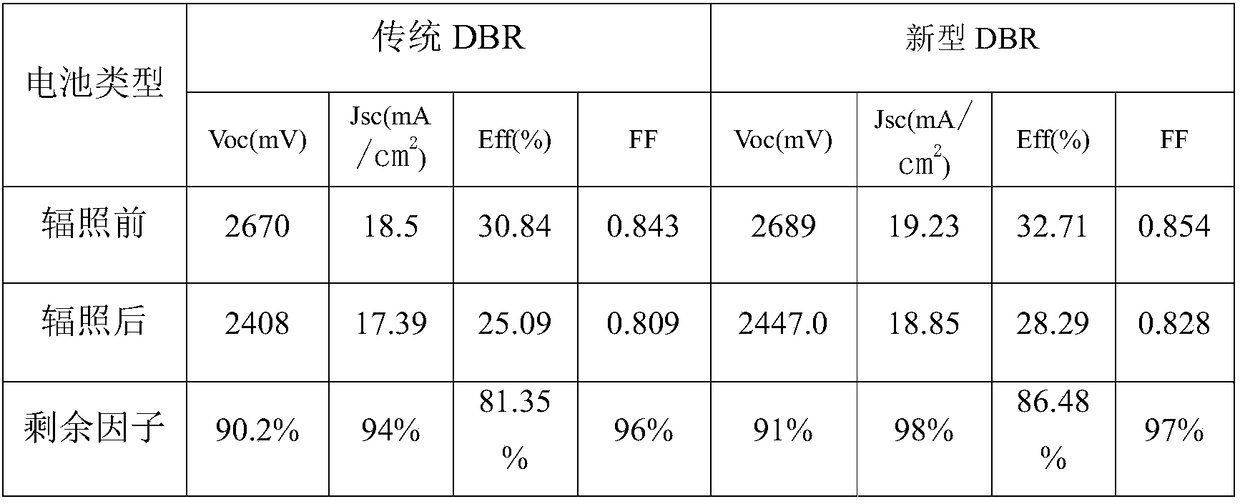

Novel DBR structure for lattice-mismatching multi-junction solar cell

PendingCN109301006AHas rigidityPromote absorptionPhotovoltaic energy generationSemiconductor devicesLattice mismatchRefractive index

The invention discloses a novel DBR structure for a lattice-mismatching multi-junction solar cell, and the novel DBR structure is a GaInNAs / AlGaInAs periodic structure superimposed on a lattice gradual change buffer layer, and is made of two alloy materials: GaInNAs and AlGaInAs. GaInAs subcells are stacked on the GaInNAs / AlGaInAs periodic structure, and the GaInNAs refractive index of the GaInNAs / AlGaInAs periodic structure is higher than that of AlGaInAs, and there is lattice mismatching between GaInNAs and AlGaInAs and between GaInAs and a base region material GaInAs of the GaInAs subcells,wherein the mismatching degree is not greater than 3%. The strain compensation structure facilitates the stress release and dislocation slip. The structure provided by the invention can reduce the defect density in an epitaxial layer introduced by the mismatching, improves the material quality, can improve the anti-irradiation performance of the GaInAs subcells, adds the overall short-circuit current, open circuit voltage, filling factor and other technical indexes of the cells, and improves the overall photoelectric conversion of the cells.

Owner:ZHONGSHAN DEHUA CHIP TECH CO LTD

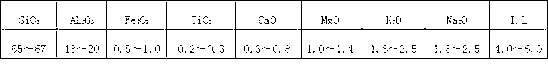

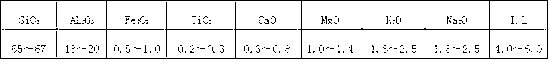

Production method of ceramic tile

The invention relates to a production method of a ceramic tile. The method is characterized by comprising the following steps of: a forming process of a ceramic tile green body; a drying process; a glazing process; a burning process; and a polishing process. The components of ceramic tile green body in the forming process of the ceramic tile green body comprise 65-67% of SiO2, 18-20% of Al2O3, 0.5-1.0% of Fe2O3, 0.2-0.3% of TiO2, 0.3-0.8% of CaO, 1.0-1.4% of MgO, 1.8-2.5% of K2O, 1.8-2.5% of Na2O and 4.0-6.0% of I.L. The glazing process consists of a surface glazing process and a polishing glazing process. Compared with the prior art, the ceramic tile has the advantages of smooth and attractive surface, and the surface pattern is easy to meet the design demand in texture.

Owner:广东博华陶瓷有限公司

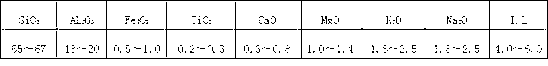

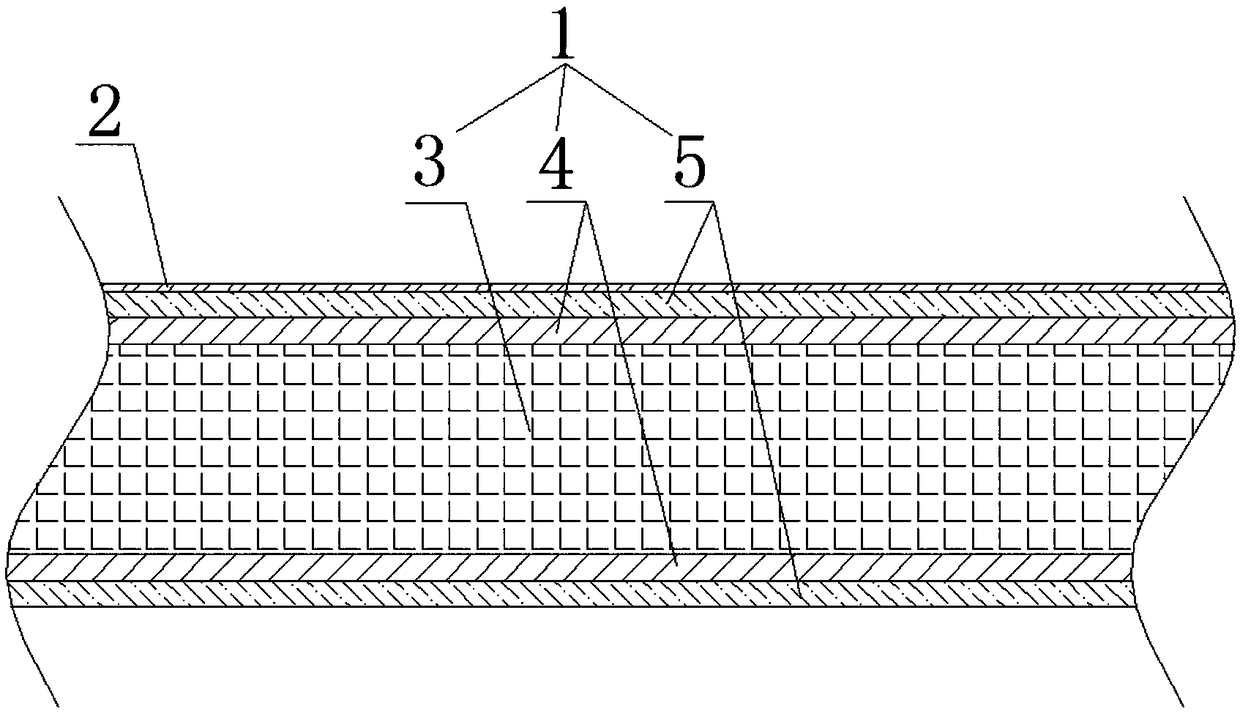

Truck exterior trimming part made of polyurethane fiber composite material

PendingCN108859168AImprove support strengthImprove impact resistanceSynthetic resin layered productsVehicle componentsTruckFilling materials

The invention discloses a truck exterior trimming part made of a polyurethane fiber composite material. The exterior trimming part comprises a top cover, a guide plate, a door sheet, a radiator grille, pedals and a bumper which are arranged on the outside surface of a head part of a truck; the top cover, the guide plate, the door sheet, the radiator grille, the pedals and the bumper are all made of the polyurethane fiber composite material; the polyurethane fiber composite material comprises a composite sheet layer and an outer protective layer which is attached to the outer surface of the composite sheet layer; and the composite sheet layer comprises a filling material layer body, a fiber material layer body and a polyurethane material layer body, wherein the fiber material layer body andthe polyurethane material layer body are wrapped around and cover the filling material layer body in sequence from the inside to the outside. According to the technical scheme of the truck exterior trimming part made of the polyurethane fiber composite material, all parts of the truck exterior trimming part are made of the polyurethane fiber composite material through technologies such as layeredmould pressing, meanwhile, the requirements of the development trend of lightweight and high strength of the truck exterior trimming part can be met, the steps of a preparation technology are simplified, and the production cycle is short.

Owner:ZHEJIANG SANSE MOLD TECH

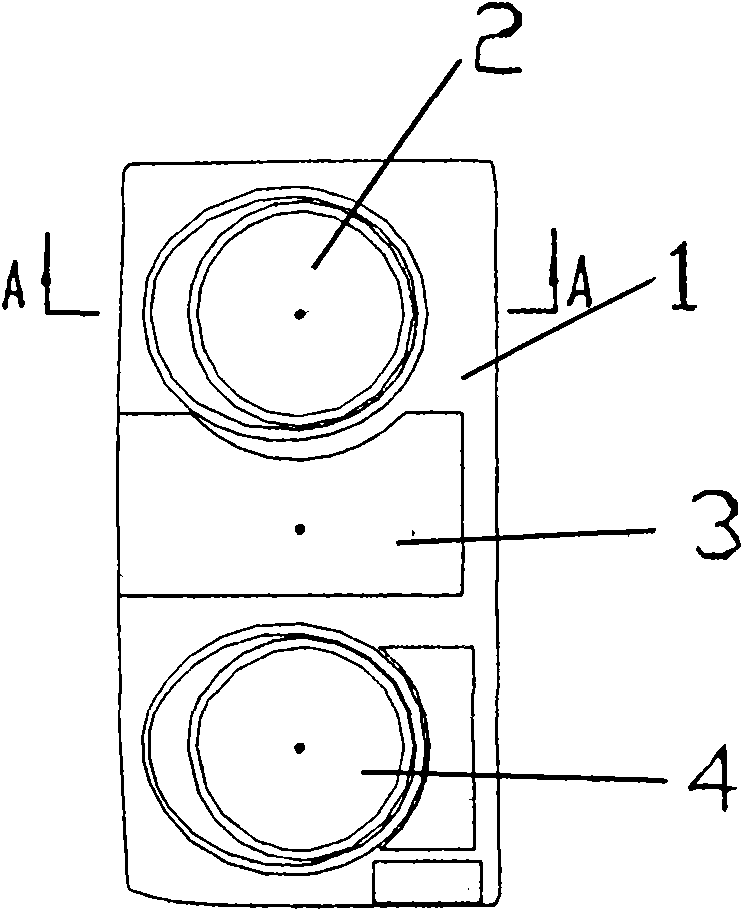

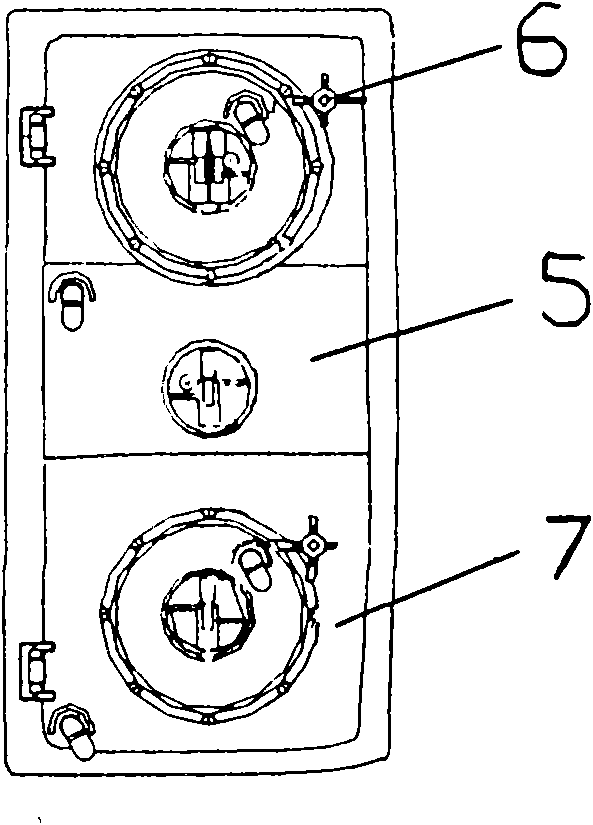

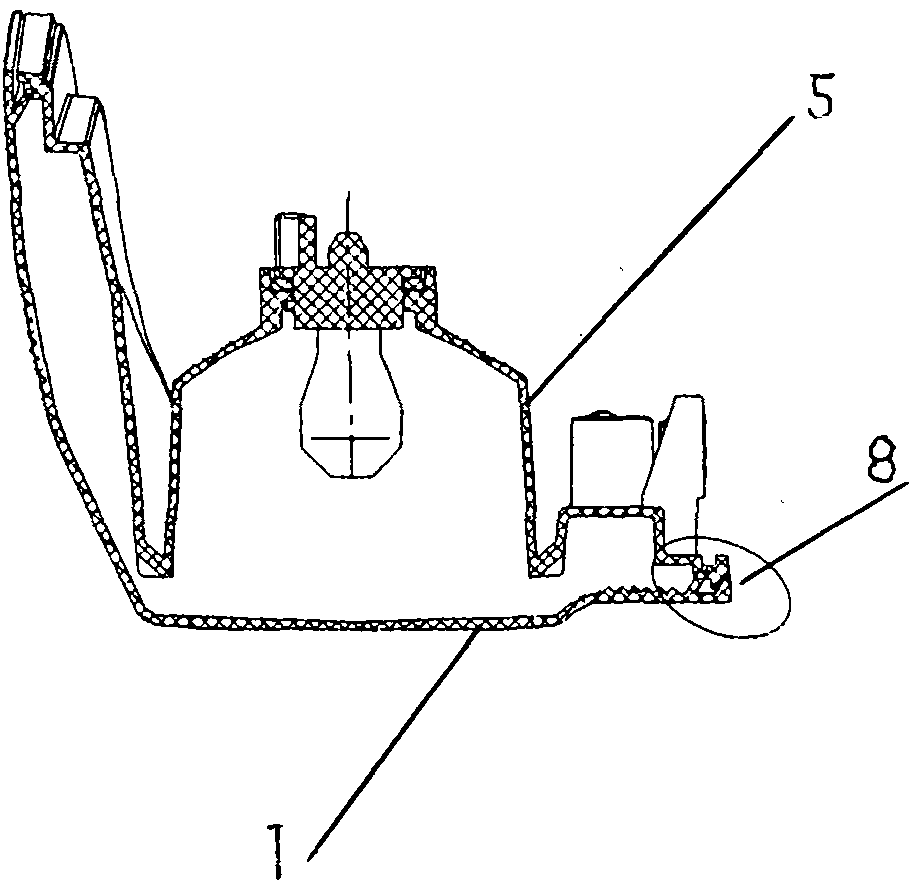

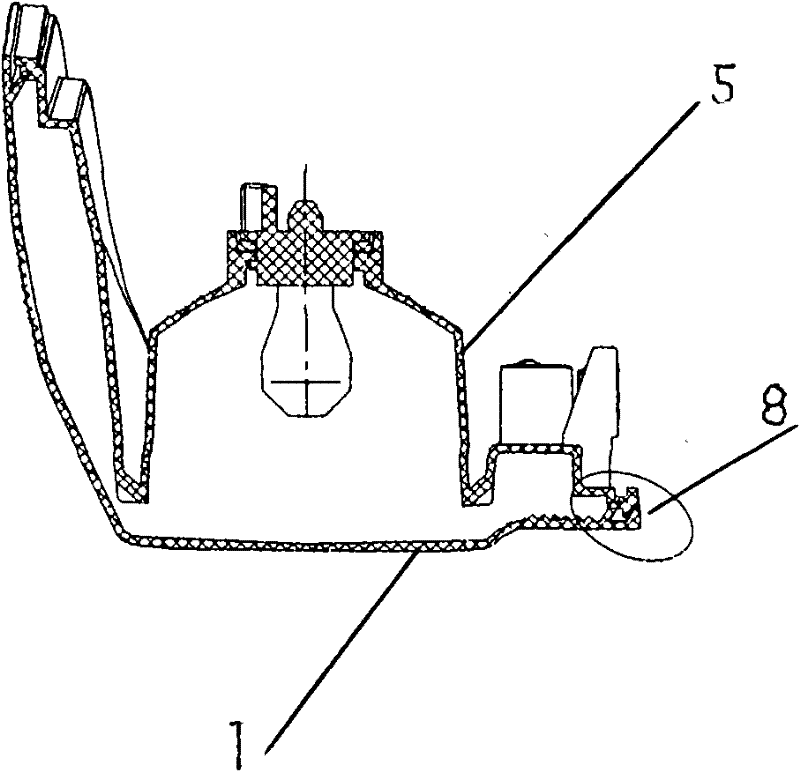

Automobile combined rear lamp structure

ActiveCN101776239AEasy to solderReduce processing difficultyOptical signallingLight fasteningsEngineeringSignal lamp

The invention discloses an automobile combined rear lamp structure, which comprises a lamp housing, a brake lamp / rear position lamp, a rear steering signal lamp and a rear fog lamp / backup lamp, wherein the brake lamp / rear position lamp, the rear steering signal lamp and the rear fog lamp / backup lamp are arranged on the lamp housing. The invention is characterized in that a welded limiting rib is arranged on the right side of a lens, the welded limiting rib protrudes upward, the vertical section of the welded limiting rib is approximately trapezoidal, and the welded limiting rib is fixedly connected with a small limiting boss arranged on the right side of the lamp housing; a primary positioning pin is arranged at the upper part on the right side behind the lamp housing and a secondary positioning pin is arranged at the lower part on the right side behind the lamp housing; a primary positioning hole and a second positioning hole are arranged on a rail lamp reinforcement, and the primary positioning pin and the secondary positioning pin arranged behind the lamp housing are respectively matched with the primary positioning hole and the secondary positioning hole. The invention has the advantages that the welding is firm, water is not apt to enter and the service life is long; and the positioning is accurate and the installation is stable.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

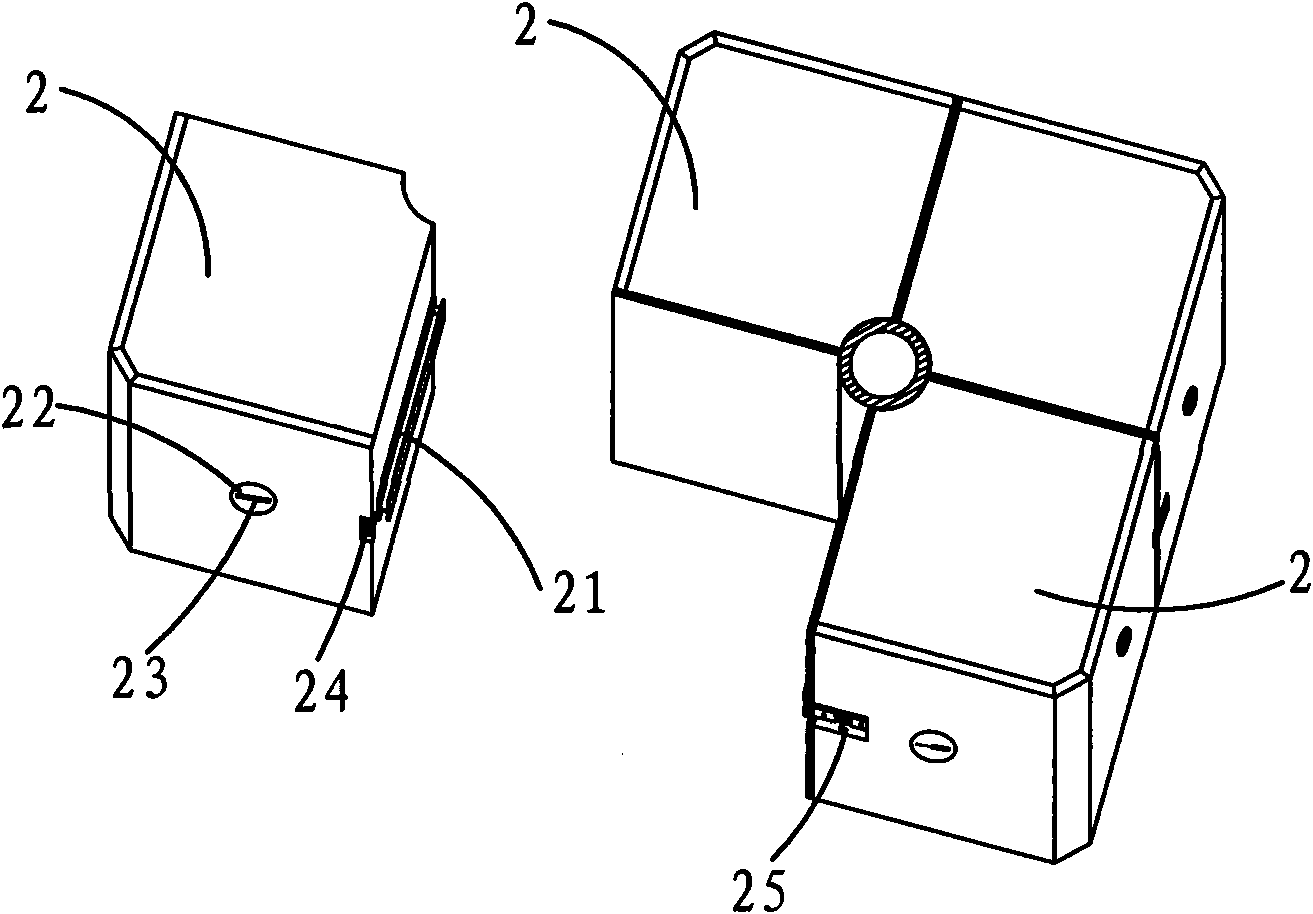

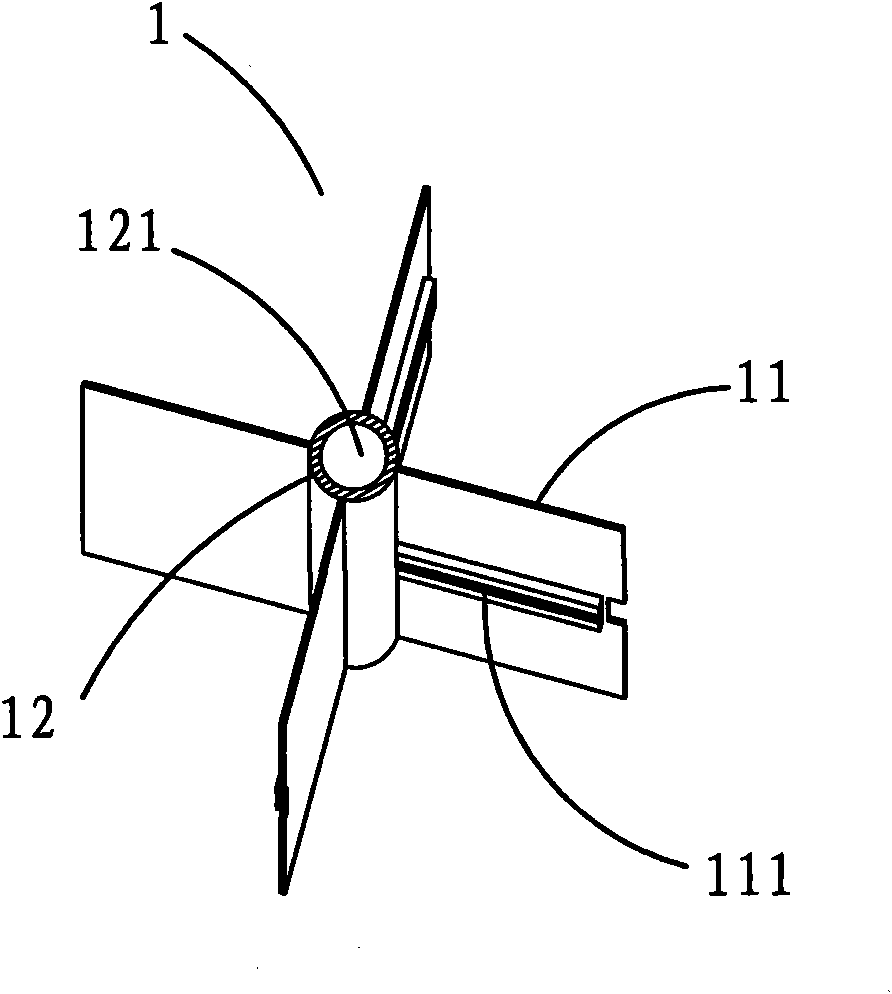

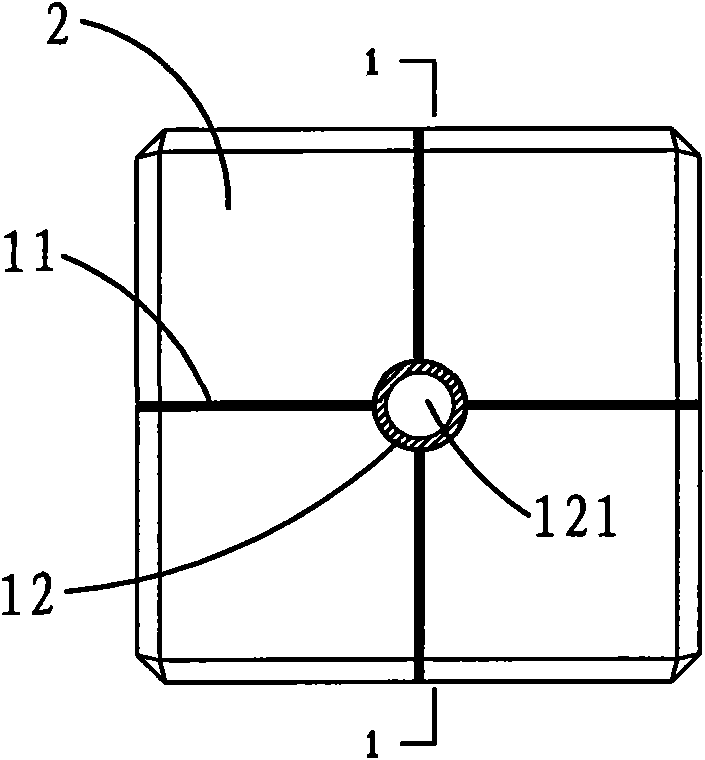

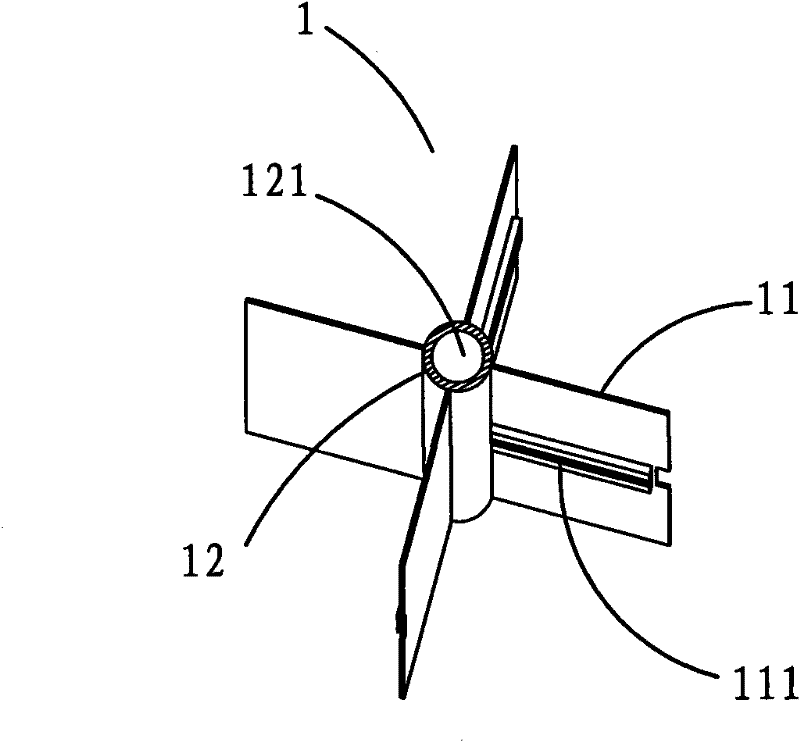

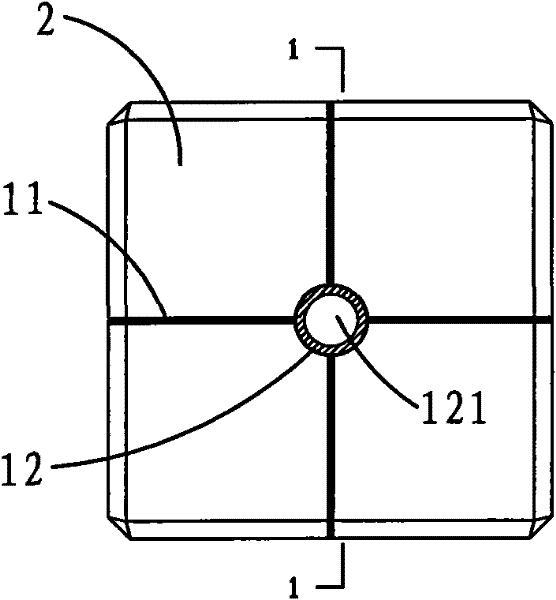

Freely combined diamond die with fixed bracket

ActiveCN102051976AOptimize layoutImprove the forceBuilding componentsForms/shuttering/falseworksReinforced concreteRebar

The invention relates to a reinforced concrete internal model, in particular to a freely combined diamond die with a fixed bracket, which comprises a fixed bracket and a plurality of small diamond dies, wherein adaptive sliding rails are respectively arranged on the fixed bracket and the small diamond dies, and the small diamond dies form the combined diamond die through arranging the sliding rails on the bracket. The fixed bracket comprises a cylinder shaft and four high-strength blades, wherein the blades are mutually vertically and uniformly fixed on the side wall of the cylinder shaft, and sliding rails adapted to the side walls of the square diamond dies are respectively arranged on the side surfaces of the blades along a clockwise direction or anticlockwise direction. The invention is convenient for positioning and easy for construction, is favorable for conveniently solving the contradiction of medium-small embedded parts and the installation of the box body, and is easy to ensure that the concrete is compact.

Owner:林荣

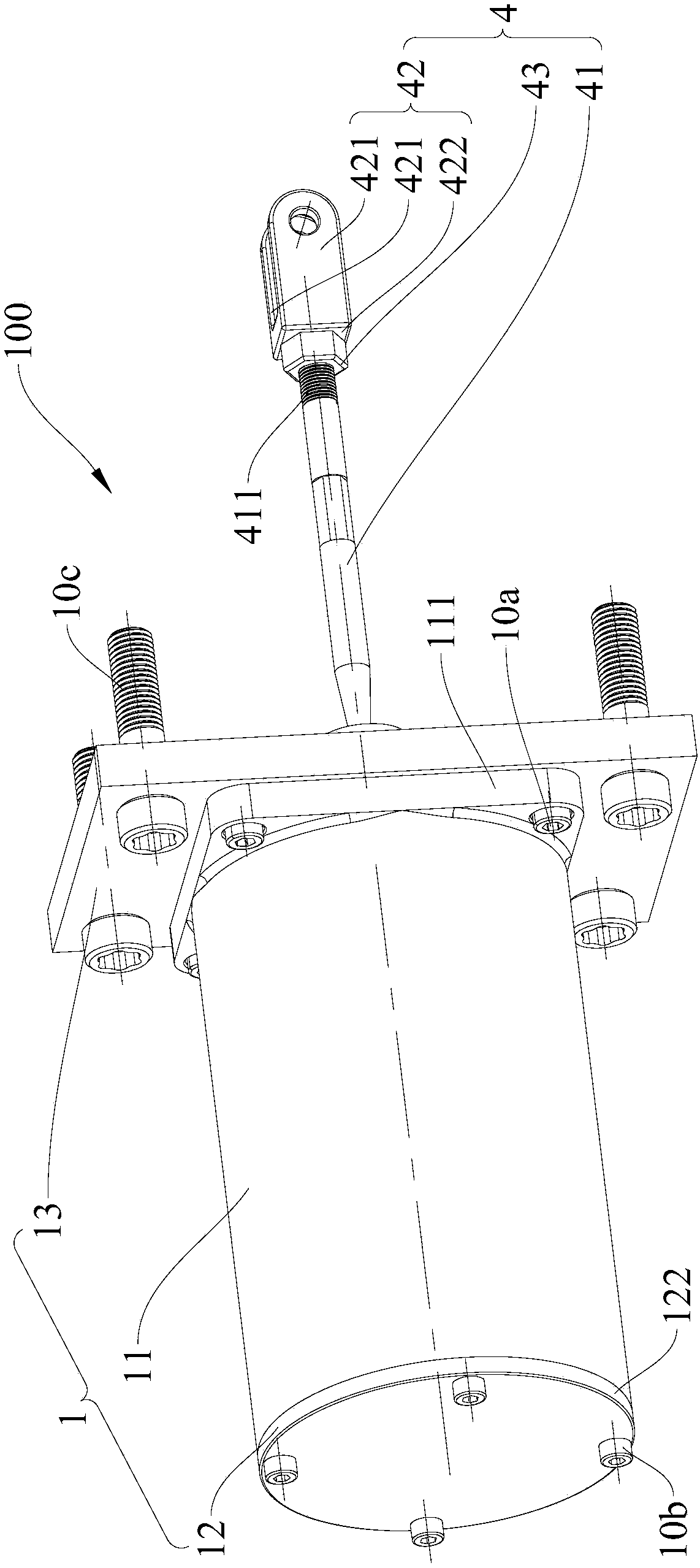

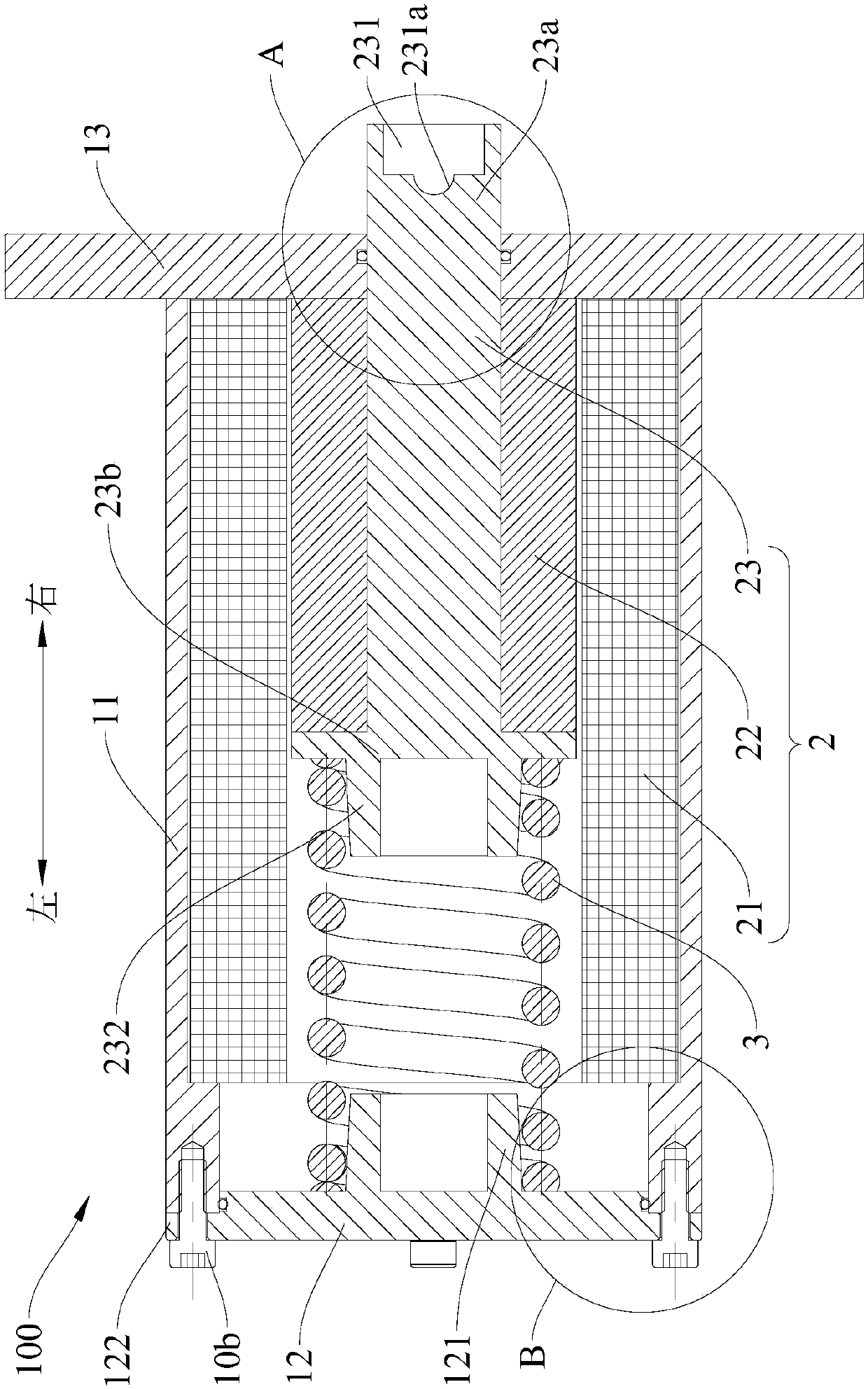

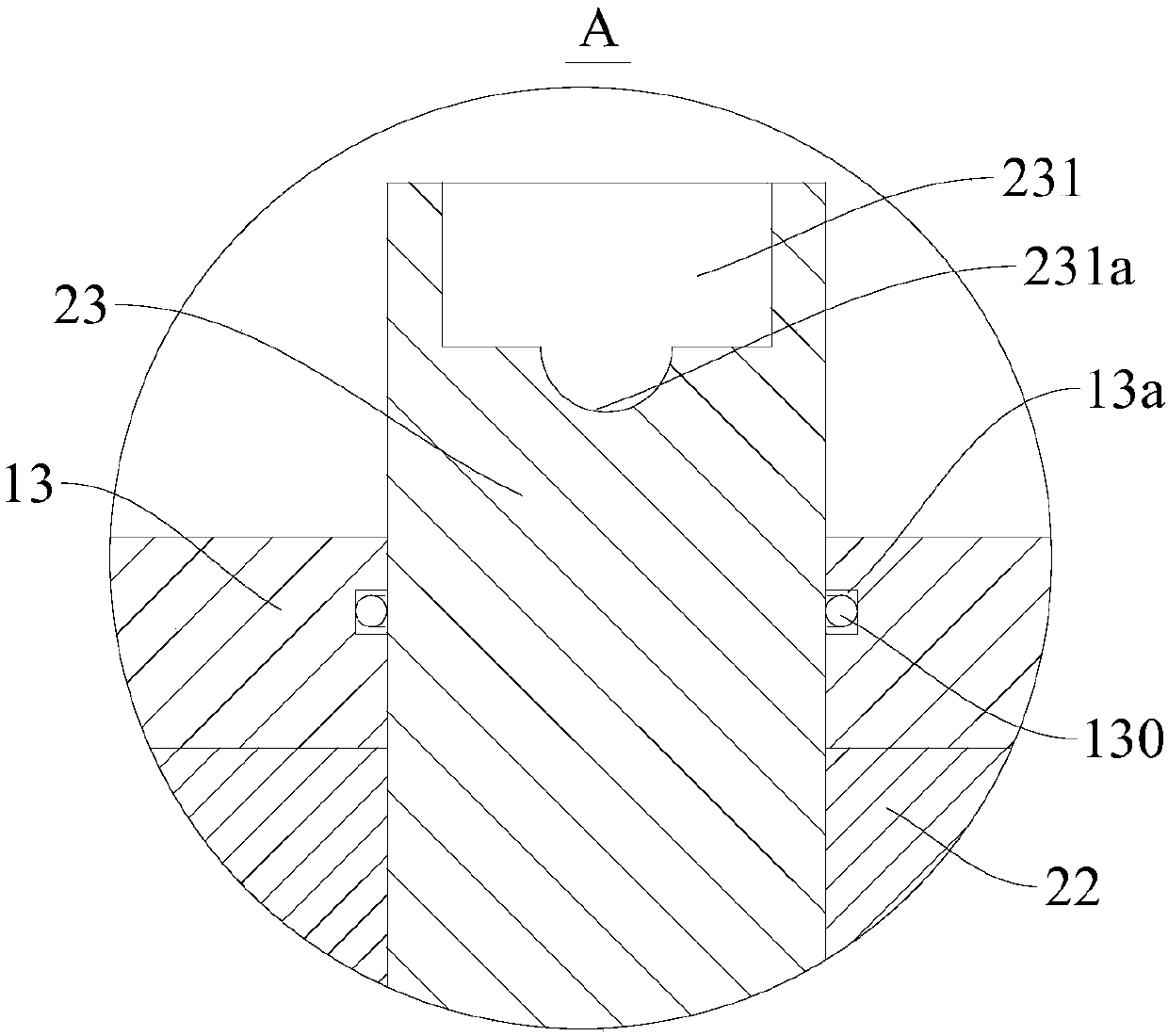

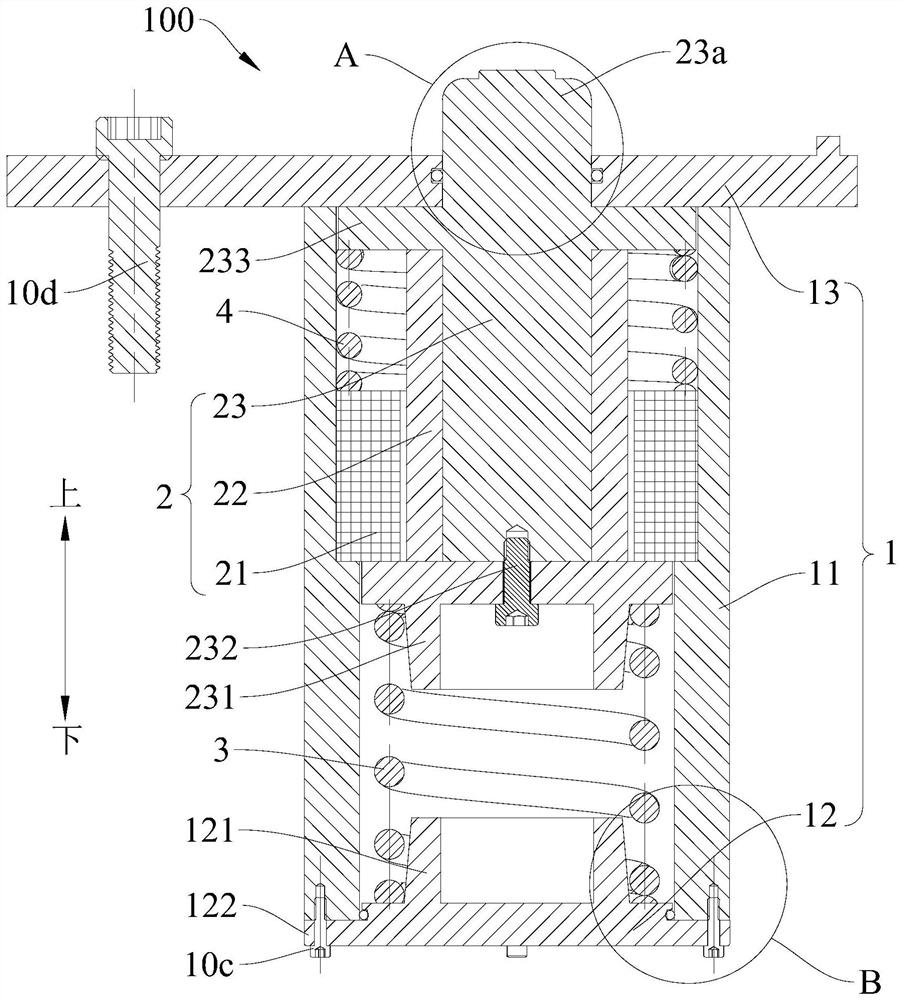

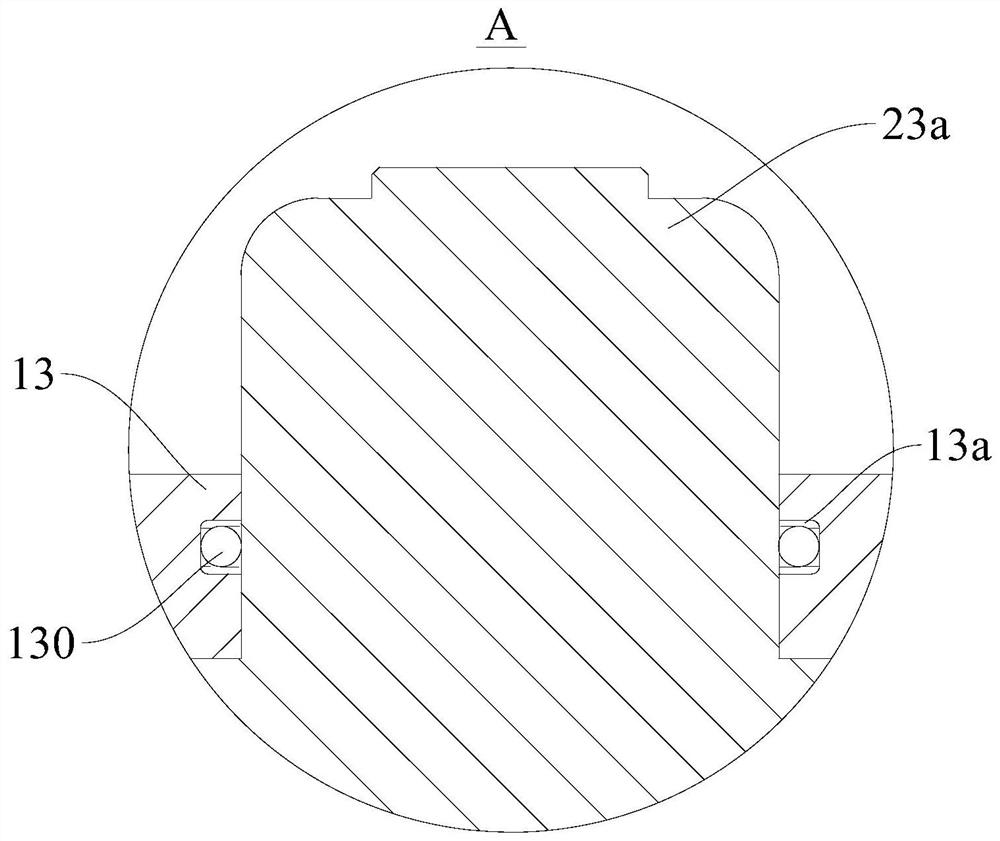

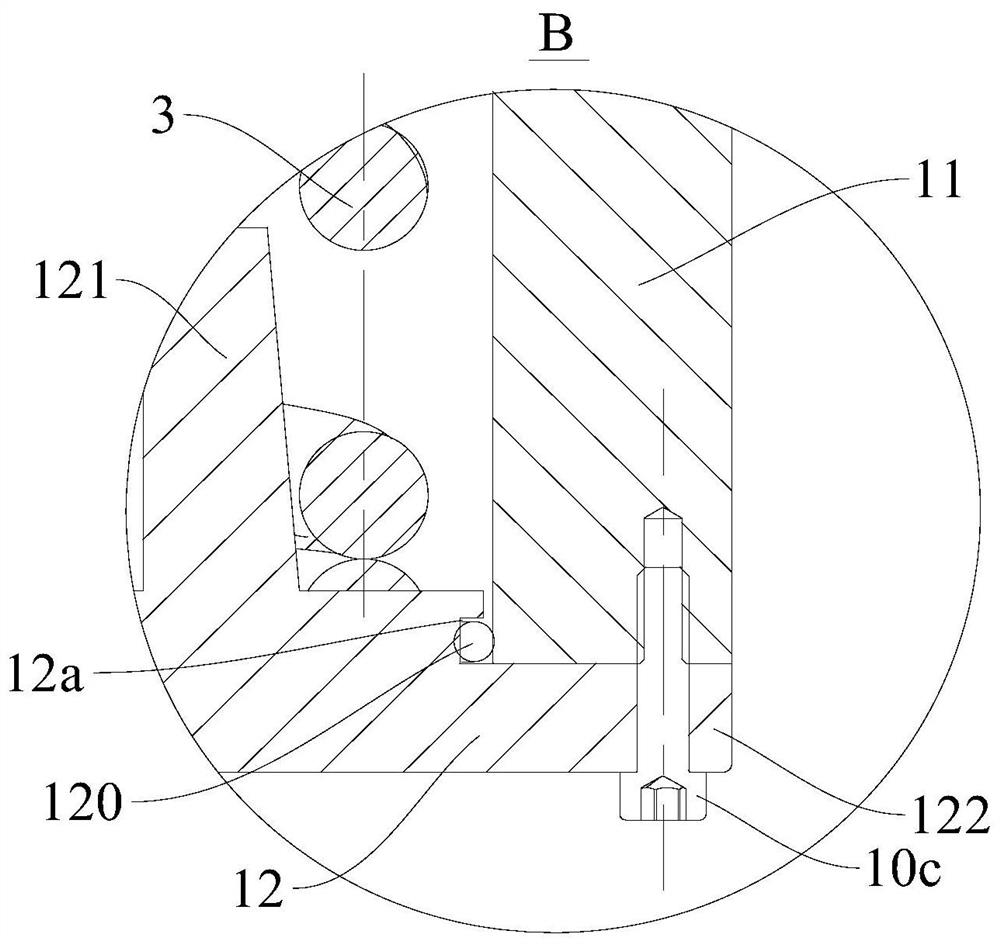

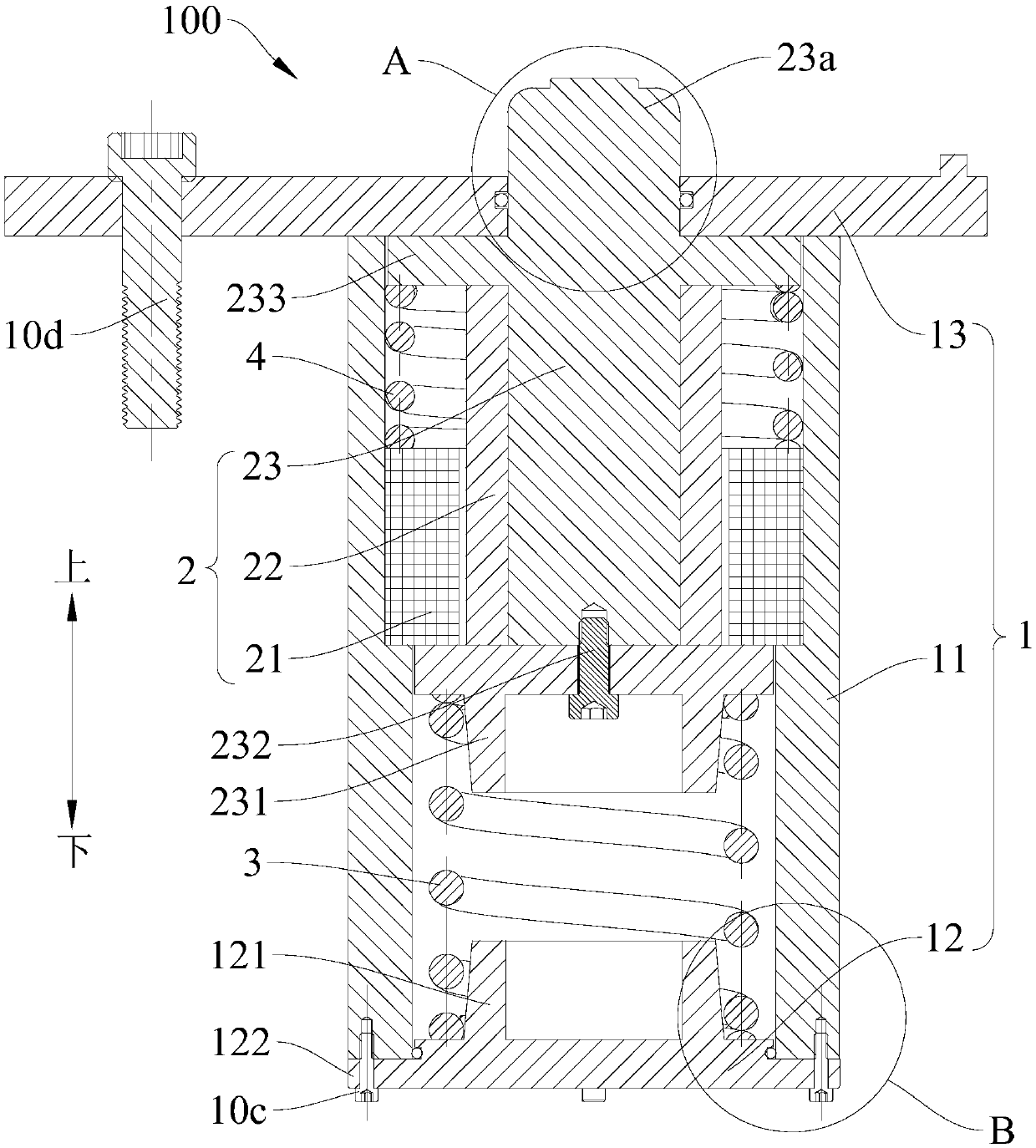

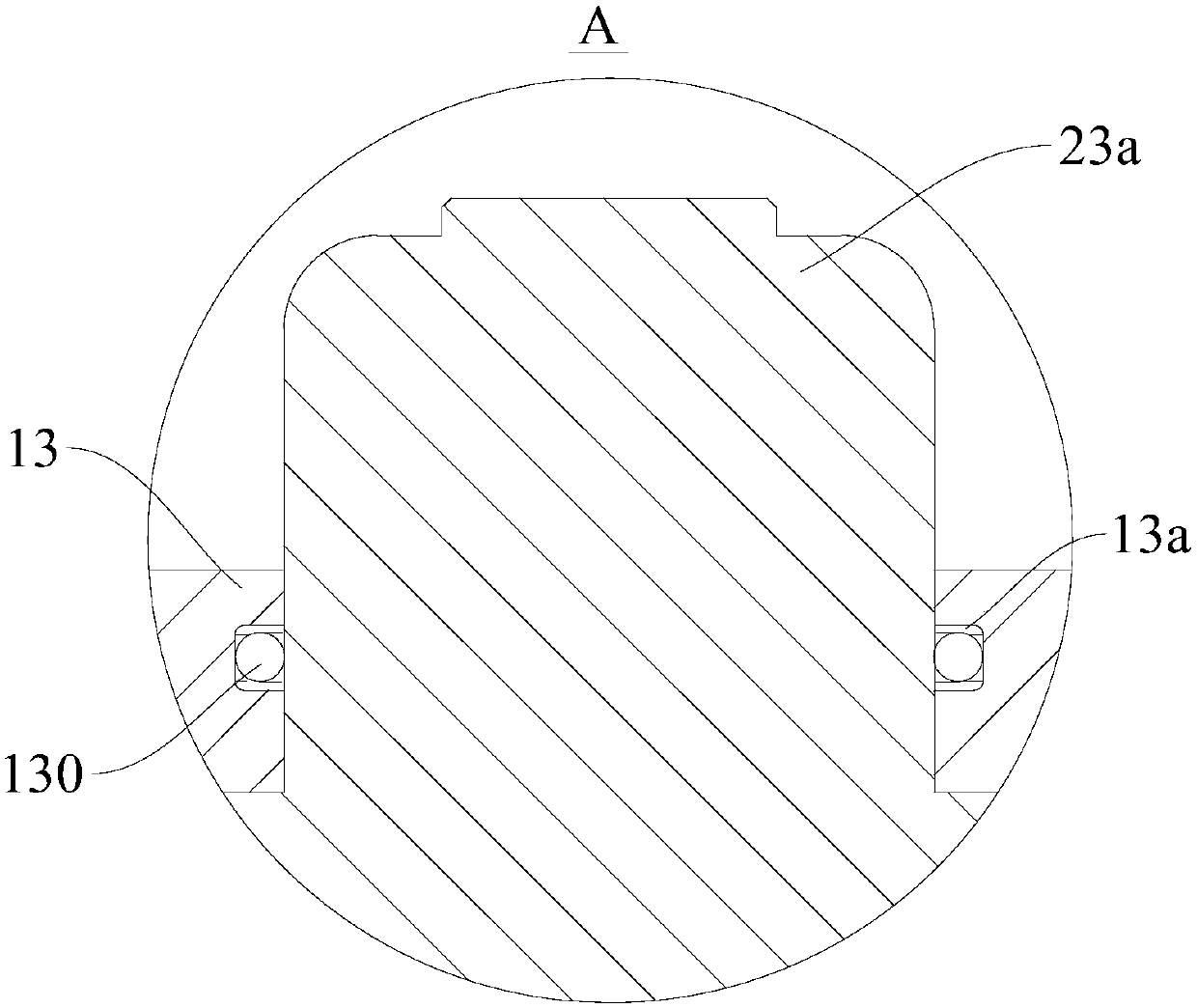

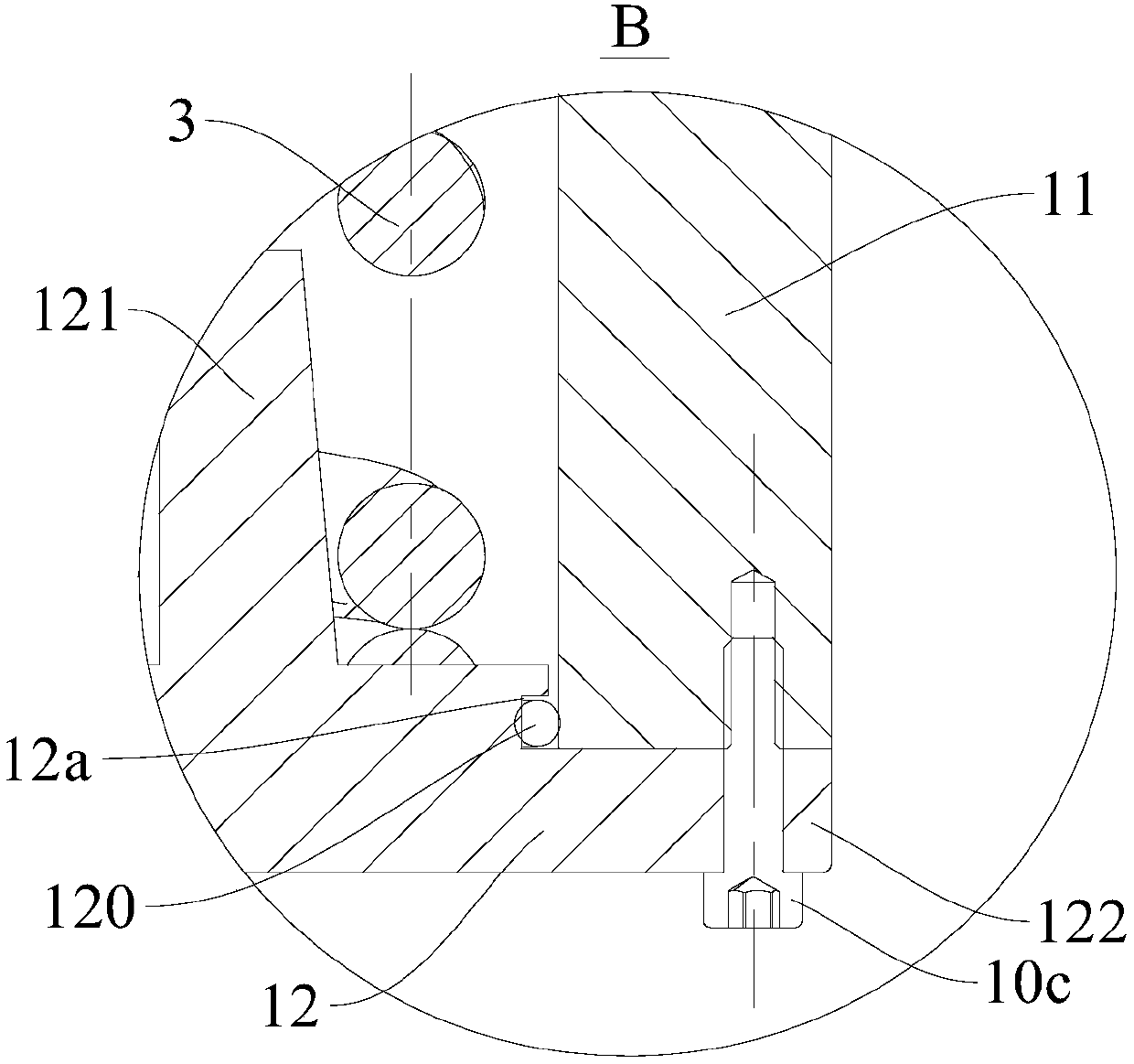

Pedal-feeling simulator for vehicle and vehicle with pedal-feeling simulator

The invention discloses a pedal-feeling simulator for a vehicle and the vehicle with the pedal-feeling simulator. The vehicle comprises a pedal, and the pedal-feeling simulator comprises a shell, a linear motor and an elastic part; and the linear motor comprises a motor primary part, a motor secondary part and a motor push rod, the motor primary part is fixed to the inner wall of the shell, the motor secondary part is arranged in the motor primary part, the motor secondary part is matched with the motor primary part so as to enable the motor secondary part to axially move relative to the motorprimary part, the motor secondary part sleeves the motor push rod to drive the motor push rod to move synchronously, the first end of the motor push rod extends out of the shell to be suitable for being connected with the pedal, and the elastic part is used for applying elastic force to the motor push rod. The pedal-feeling simulator for the vehicle is high in response speed, has a good braking effect, and meanwhile can provide a good 'brake feeling', especially a pedal braking feeling, for a driver.

Owner:BYD CO LTD

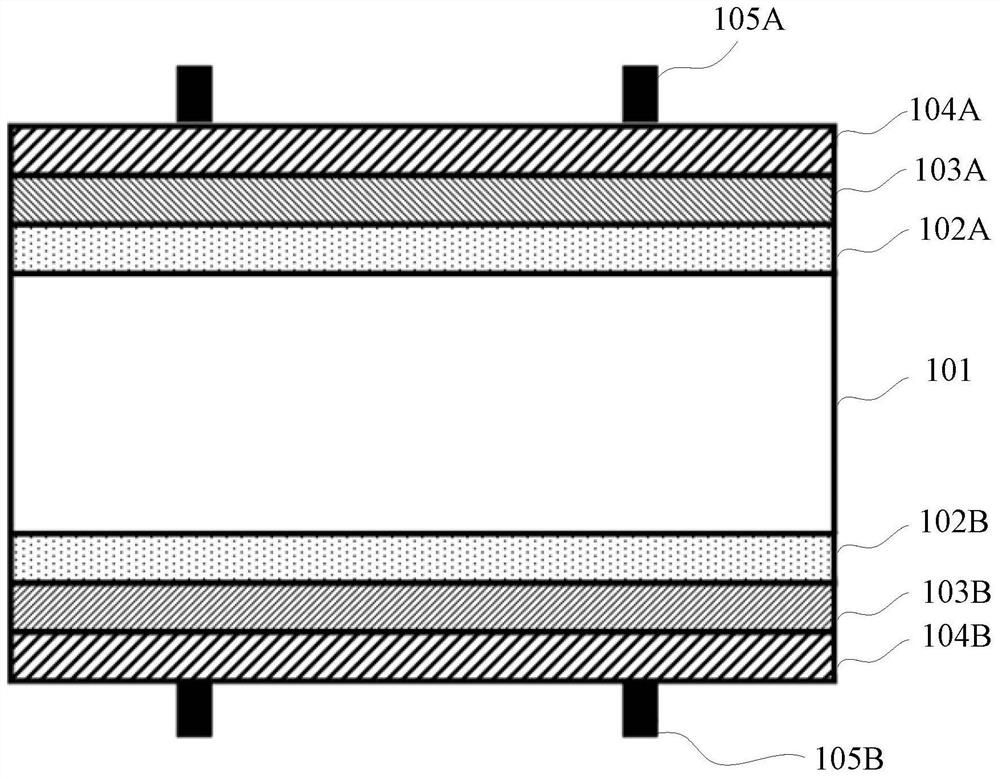

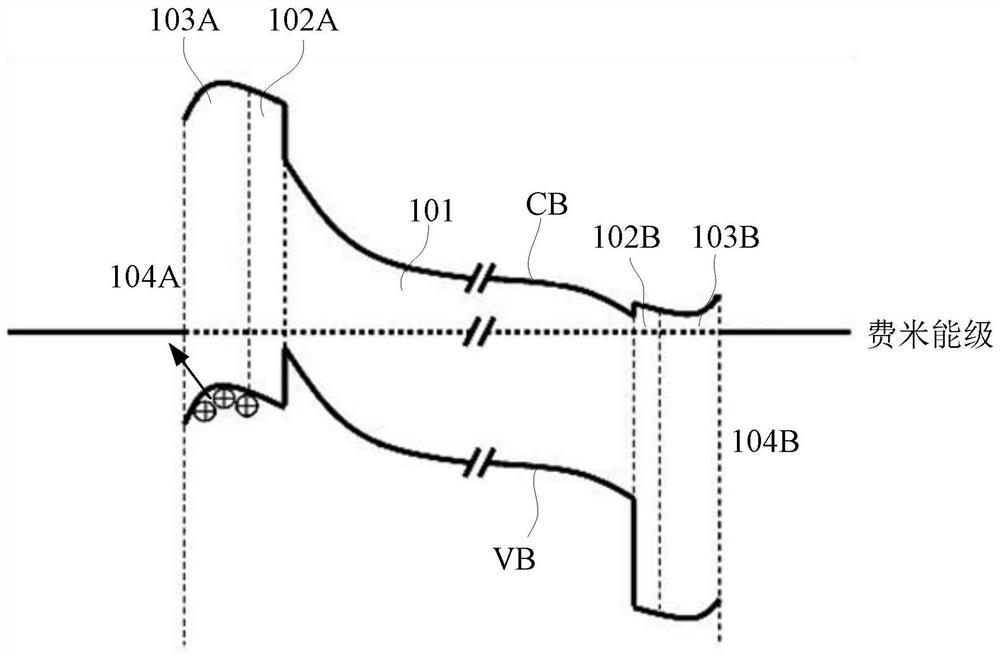

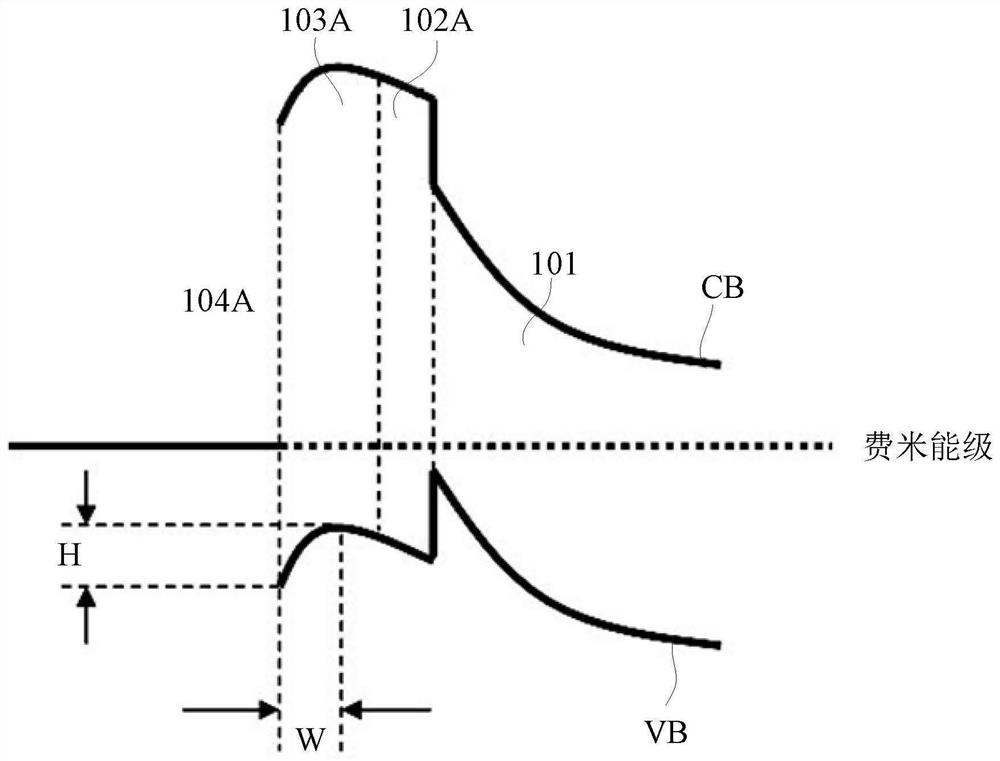

Silicon heterojunction cell and manufacturing method thereof

ActiveCN112466977AReduce or eliminate the impactSimplified forecasting modelPhotovoltaic energy generationSemiconductor devicesHeterojunctionSchottky barrier

The invention discloses a silicon heterojunction cell and a manufacturing method thereof, relates to the technical field of solar cells, and aims to reduce a Schottky barrier between a P-type doped silicon layer and a transparent conductive layer and reduce the width of a depletion layer of the P-type doped silicon layer so as to improve the hole collection capability and improve the cell performance. The silicon heterojunction cell comprises a silicon substrate, an interface inversion layer and a first transparent conductive layer. The silicon substrate includes a doped silicon substrate, a P-type doped silicon layer, and a first intrinsic silicon layer formed between the doped silicon substrate and the P-type doped silicon layer. The interface inversion layer is formed on the P-type doped silicon layer. The first transparent conductive layer is formed on the interface inversion layer. The interface inversion layer contains polar organic molecules. The polar organic molecules are bonded with silicon atoms in the P-type doped silicon layer. The interface inversion layer has a dipole moment pointing from the transparent conductive layer to the P-type doped silicon layer. The manufacturing method of the silicon heterojunction battery is used for manufacturing the silicon heterojunction battery. The silicon heterojunction battery provided by the invention is used for photovoltaicpower generation.

Owner:LONGI GREEN ENERGY TECH CO LTD

Super high-rise pump concrete and preparation method thereof

InactiveCN110885213AReinforcement intensity levelReduced difficulty of pumpingSilicic acidCarboxylic acid

The invention discloses super high-rise pump concrete and a preparation method thereof. The super high-rise pump concrete comprises the components: silicic acid cement, ground granulated blast furnaceslag powder, fly ash, micro-bead powder, water, a fine aggregate, a coarse aggregate, an anionic surfactant and an additive. The preparation method comprises the steps: weighing a certain amount of the silicic acid cement, ground granulated blast furnace slag powder, fly ash, micro-bead powder, water, fine aggregate, coarse aggregate, anionic surfactant and polycarboxylic acid high-performance water reducer for later use, and mixing the silicic acid cement, ground granulated blast furnace slag powder, fly ash, micro-bead powder, water, fine aggregate, anionic surfactant and polycarboxylic acid high-performance water reducer together; and after stirring with a stirrer, adding the coarse aggregate and stirring again until the specified slump is reached, and discharging. By improving the formula of the concrete, when the concrete is pumped to a super high-rise building, the pumping difficulty is reduced, meanwhile, the rated strength grade of the concrete is enhanced, and the strength easily meets the design requirement.

Owner:桐乡市亚都混凝土有限公司

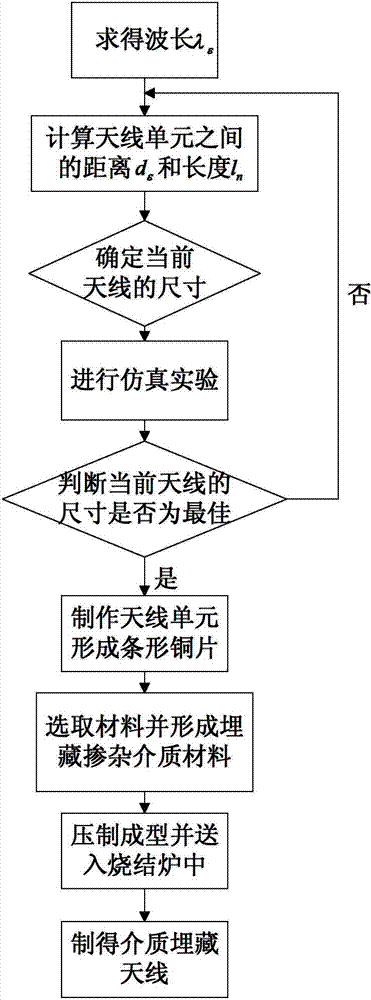

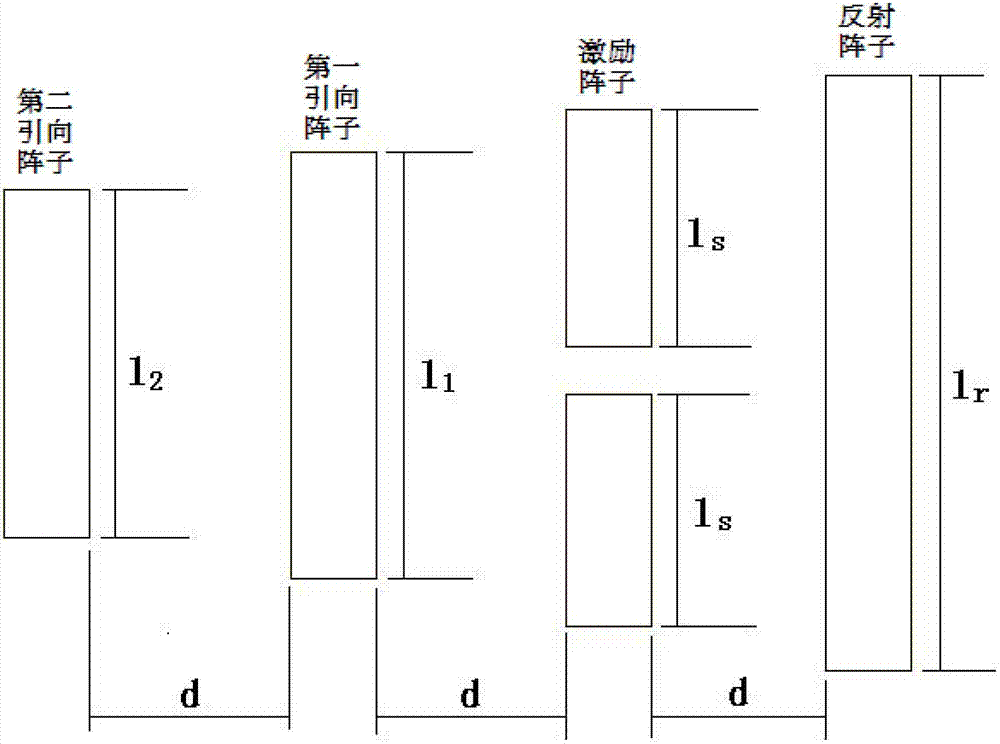

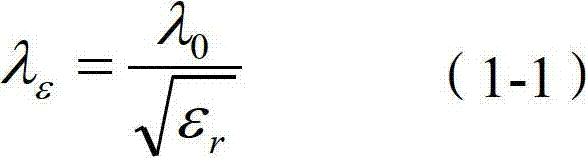

Method for preparing buried medium antenna

InactiveCN102810723AReduce volumeNot susceptible to corrosionRadiating elements structural formsMicrowaveRare earth

The invention provides a method for preparing a buried medium antenna, and belongs to the technical field of electromagnetic fields and microwaves. The preparation method comprises the following steps of: totally burying a self-designed copper antenna into a ceramic medium material doped with an yttrium group of rare earth formula to ensure that a metal part of the antenna is not exposed; forming and manufacturing the copper antenna; sintering the copper antenna at a specific temperature; and manually reducing the temperature of the sintered copper antenna to prepare the buried medium antenna of which the metal part of the antenna can be seamlessly integrated with a buried medium. By the ceramic medium, the antenna is subjected to the sintering and is buried into the ceramic medium, so that the antenna can be seamlessly integrated with the ceramic medium to guarantee stable performance; the metal part of the antenna is insusceptible to corrosion and environmental interference on the metal part is reduced; a bismuthic acid barium-based ceramic material is adopted to fill the antenna, and a melting point of the bismuthic acid barium-based ceramic material is lower than that of a copper sheet, so that melting and deformation of the copper sheet in the sintering process are avoided, and the design requirement of the buried medium antenna can be easily met; and therefore, the rate of finished products is improved.

Owner:中国人民解放军桂林空军学院

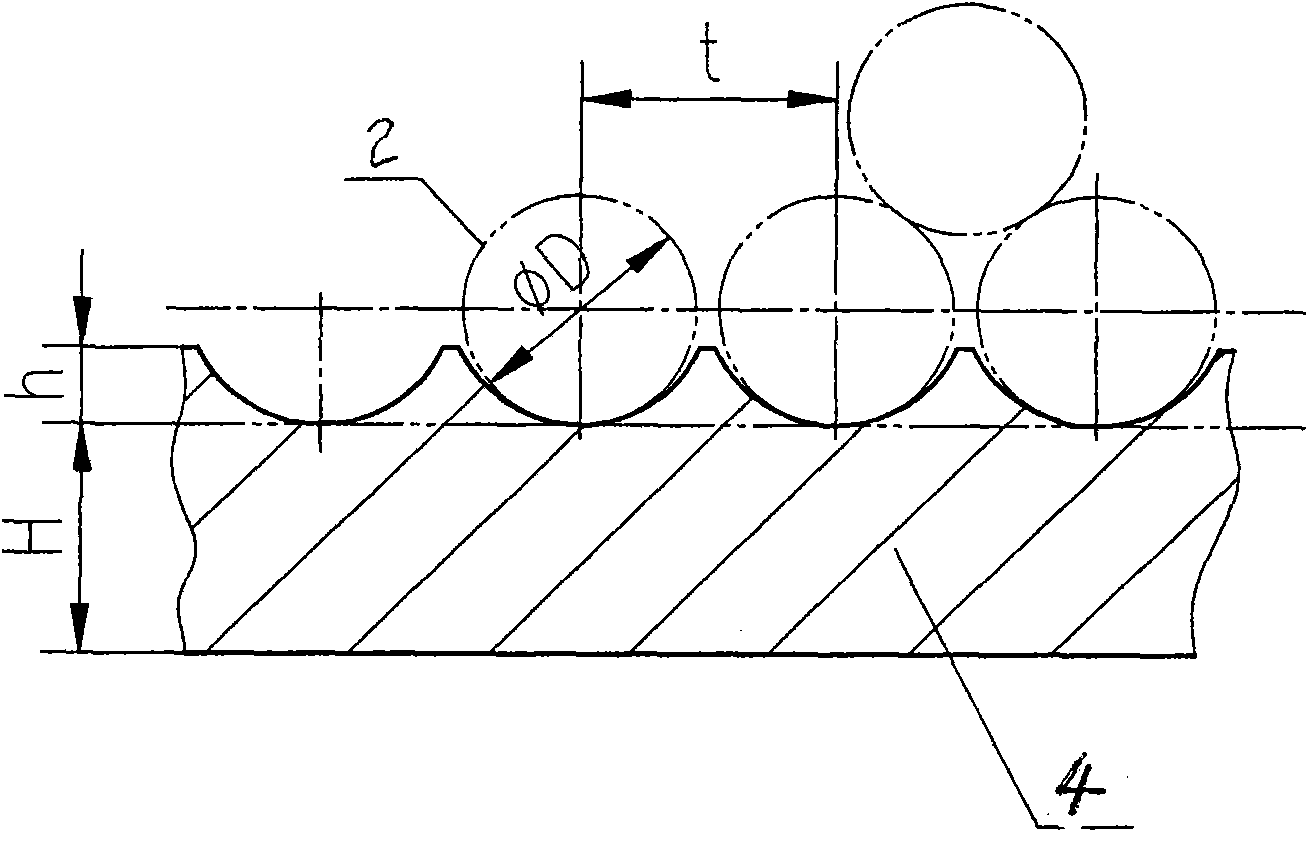

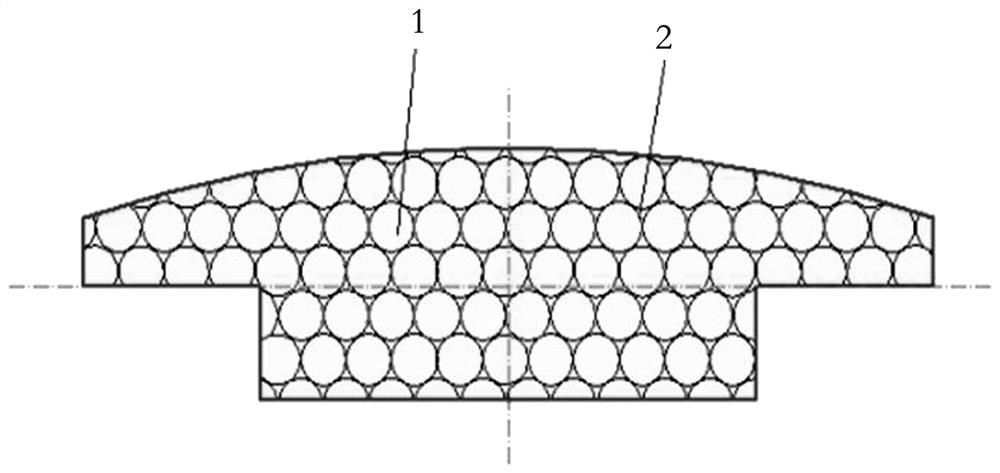

Modular assembling method for prefabricated spherical fragment of ammunition warhead

The invention discloses a modular assembling method for a prefabricated spherical fragment of an ammunition warhead. The method comprises the following steps that modularization of the prefabricated spherical fragment is conducted, specifically, according to the technical requirements for the size, quantity, dimension, quality and center of mass of the fragment, the structural requirements of an inner cavity of a warhead are met, the shape and dimension of the fragment are designed, and the fragment is vertically and horizontally divided into a plurality of small pieces, a mold is designed according to the shape and dimension of each piece; according to the design weight of each piece of fragment, the pieces of fragments are weighed and put into the mold by adopting a regular arrangement method or a vibration method as the putting method; and after the pieces of fragments are put into the mold, an adhesive is poured into the mold, gaps among the fragments are filled with the adhesive,and a module with a required shape is formed after curing, so that the fragments and the mold are modularized into a whole. Compared with the prior art, module dividing can be performed according to the shape of an inner cavity of the warhead, the fragment modules with the needed shapes are obtained through the mold, the fragment modules are bonded to the corresponding positions of the inner cavity of the warhead, and the assembling requirements of fragments of various warheads are met.

Owner:HENAN NORTHERN HONGYANG ELECTROMECHANICAL CO LTD

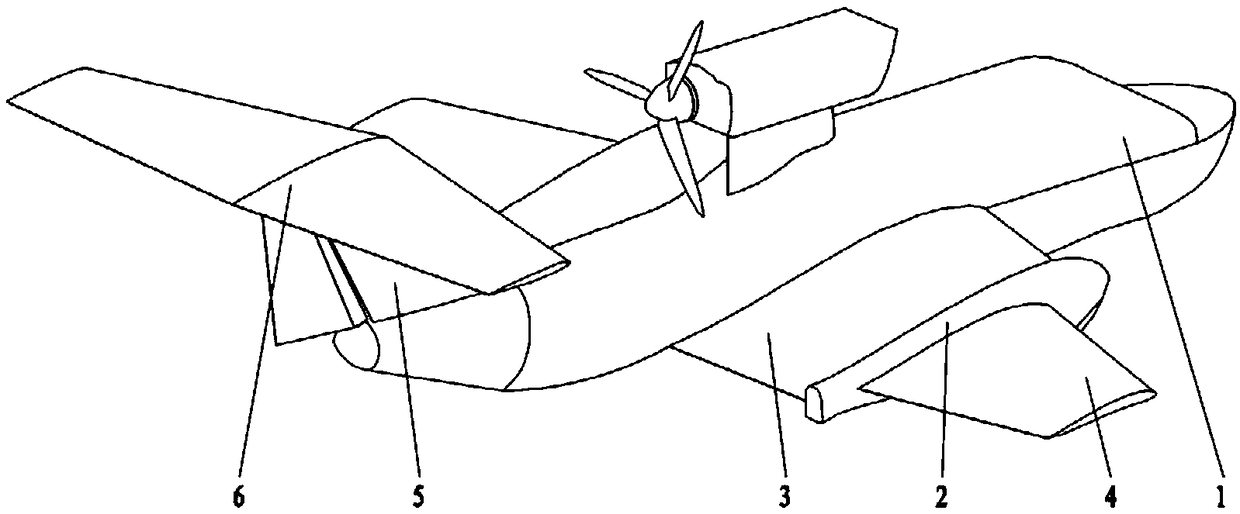

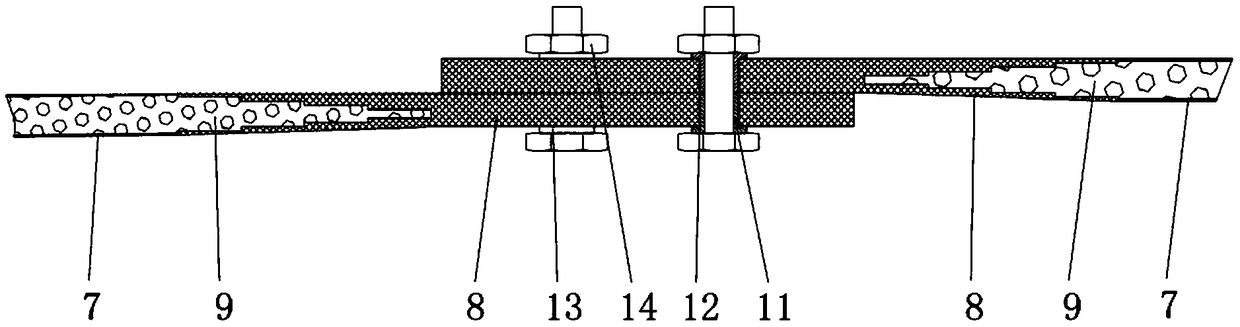

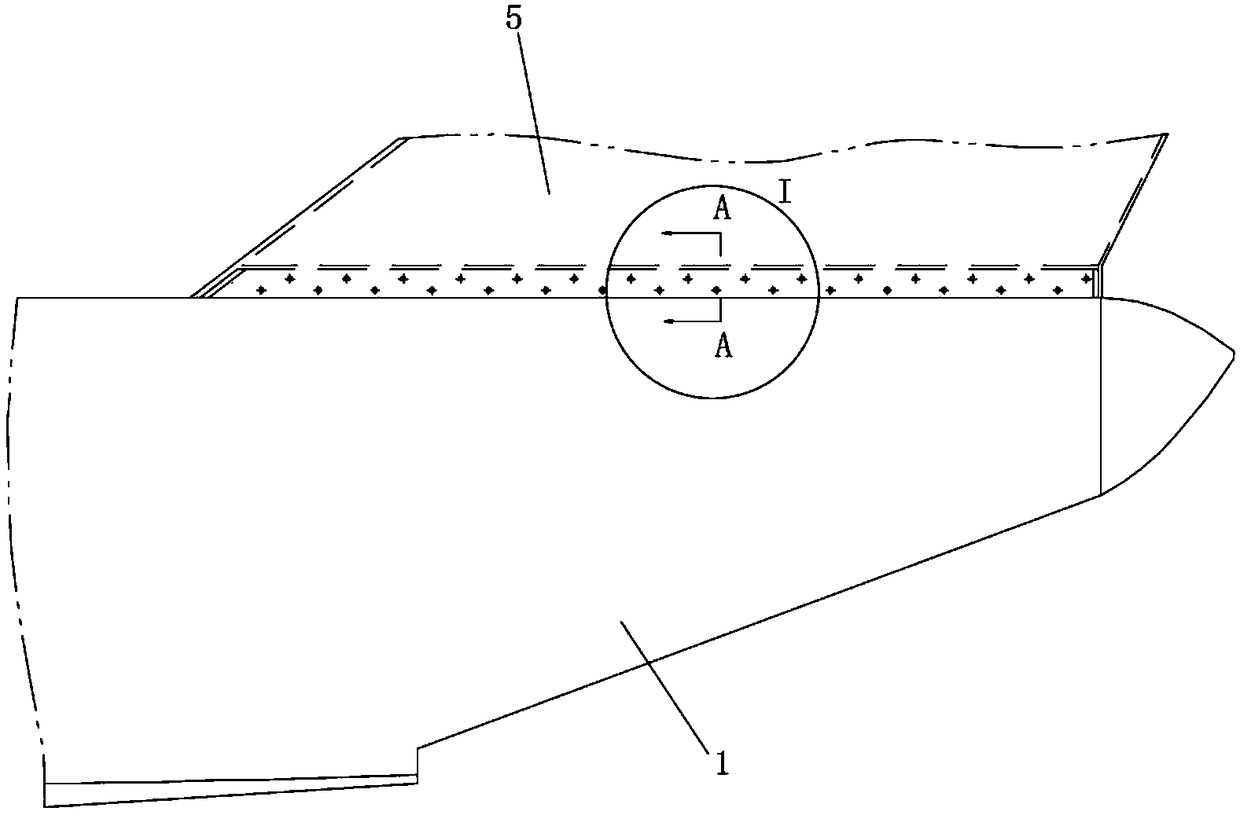

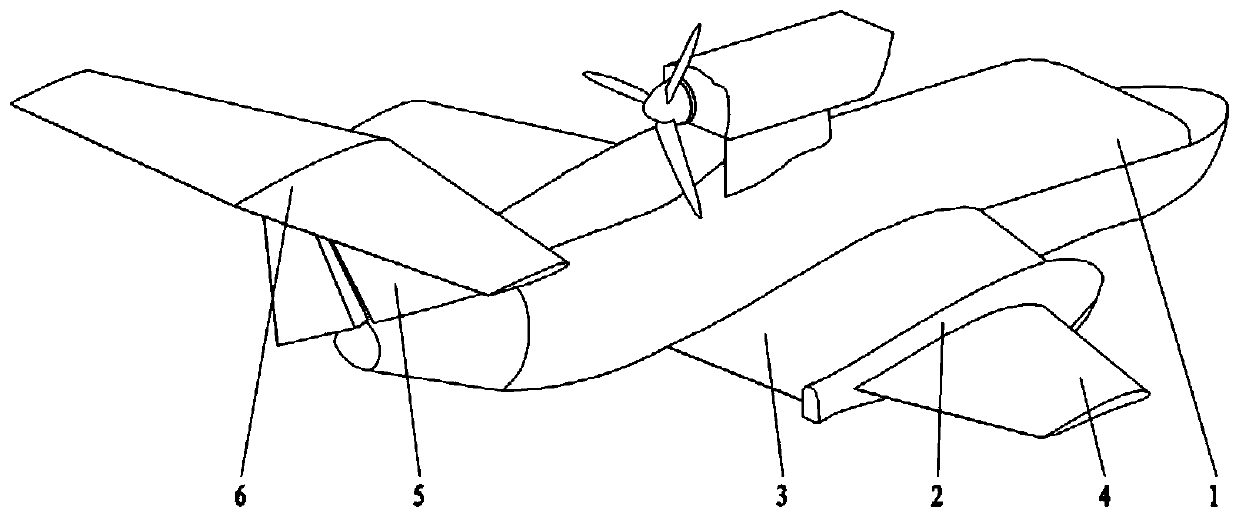

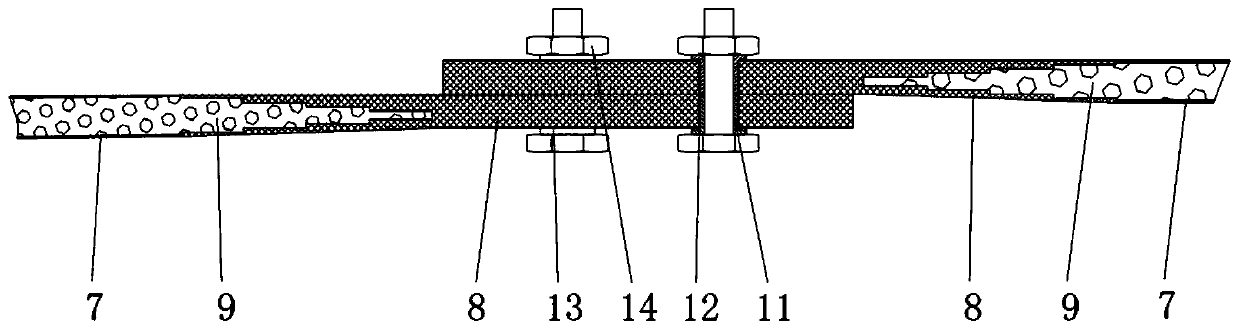

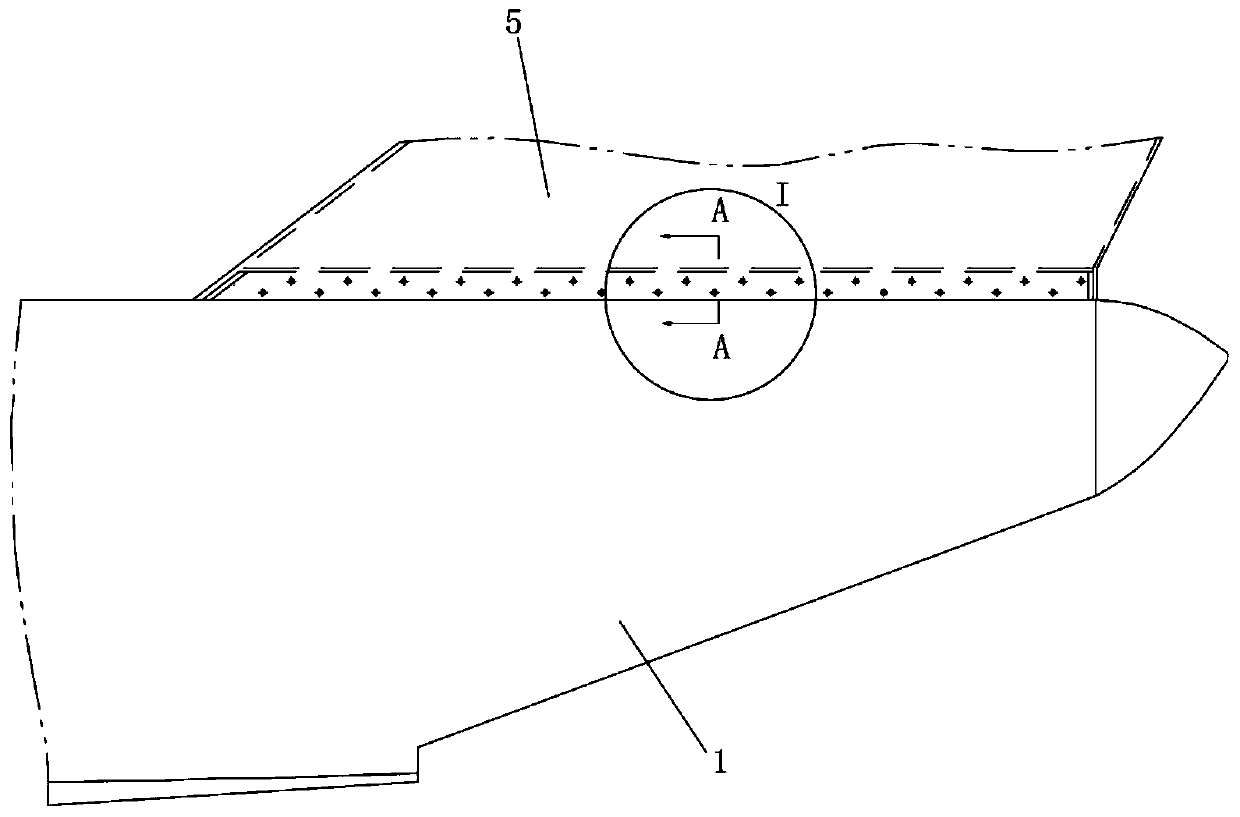

Connecting structure of all-composite winged ship

ActiveCN109229373AImproved ability to withstand concentrated loadsImprove stabilityFuselagesSeaplanesEpoxyEngineering

The invention relates to a connecting structure of an all-composite winged ship, each component of the Wing-in-Ground effect ship is provided with the same connecting part, A PVC structural foam corematerial, A FRP surface plate is arrange on that upper and lower surface of the foam core material of the PVC structure, one end of the FRP surface plate is connected with the FRP connection plate, AFRP connection layer plate is provide with a notch in that middle of the joint with the FRP surface plate, A PVC structural foam core material extend into that notch, the FRP connection layer plate isformed into a solid plate structure at one end away from the FRP surface plate, the solid plate structure of the two members to be connected overlaps upwardly and downwardly, A plurality of double-row staggered through holes are arranged at the overlapping position, a metal sleeve liner is bonded with epoxy resin in the through holes, and bolts are installed in the metal sleeve liner. The invention adopts the boss structure respectively, and the split wing box connects the hull with the aft wing and the ground effect wing, the connection is firm, and the manufacturing, disassembly and assembly are convenient, and the utilization rate of the hull space is improved.

Owner:中船重工(海南)飞船发展有限公司

Locating and turning fixture for large end face and shaft hole of valve deck of stop valve

InactiveCN103659307ASimple positioning structureEasy to manufacturePositioning apparatusMetal-working holdersVALVE PORTGlobe valve

The invention discloses a locating and turning fixture for a large end face and a shaft hole of a valve deck of a stop valve. The locating and turning fixture is composed of a fixture body, a bolt and a pressing plate. An end face retaining opening is formed in the outer side of a left disk of the fixture body. The middle portion of the end face of a right disk is provided with a cross-shaped through hole and an external step hole, wherein the outer circle of thea large end face of the valve deck to be machined is in clearance fit with the step hole. The bolt is installed on the inner end face of the left disk. The bolt and the pressing plate are matched and pressed at the edge, where a screw hole is formed, of the valve deck to be machined to form an axial locking structure. The locating and turning fixture conducts clamping under the locating condition, turning of the large end face and the screw hole of the valve deck can be completed in one step, the subsidiary time is short, and production efficiency is high. Above all, turning is conducted under the same locating datum condition, a locating error is set, and the positional accuracy of a turned product meets the design requirement easily.

Owner:JIANGSU ZHONGHAO MARINE VALVE MFG

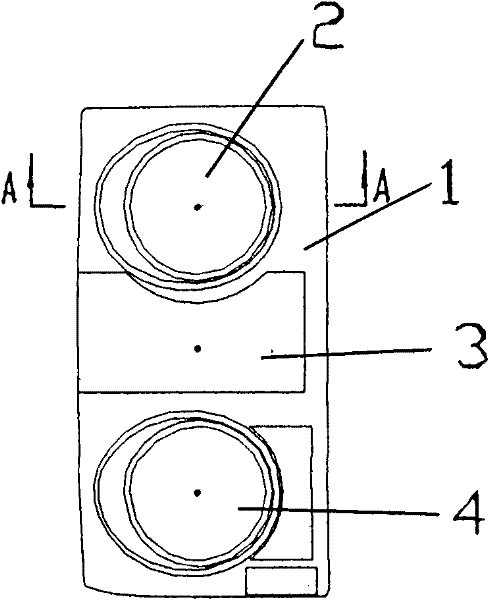

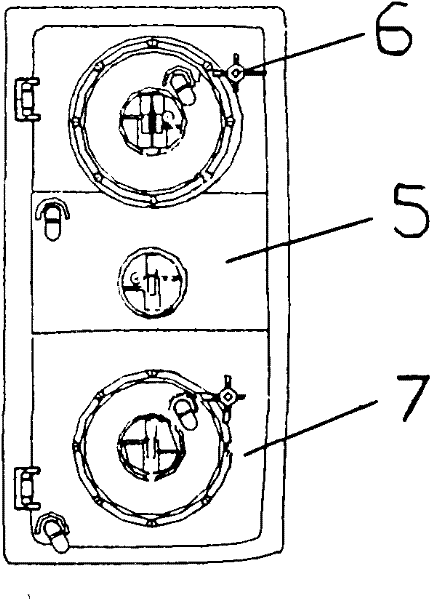

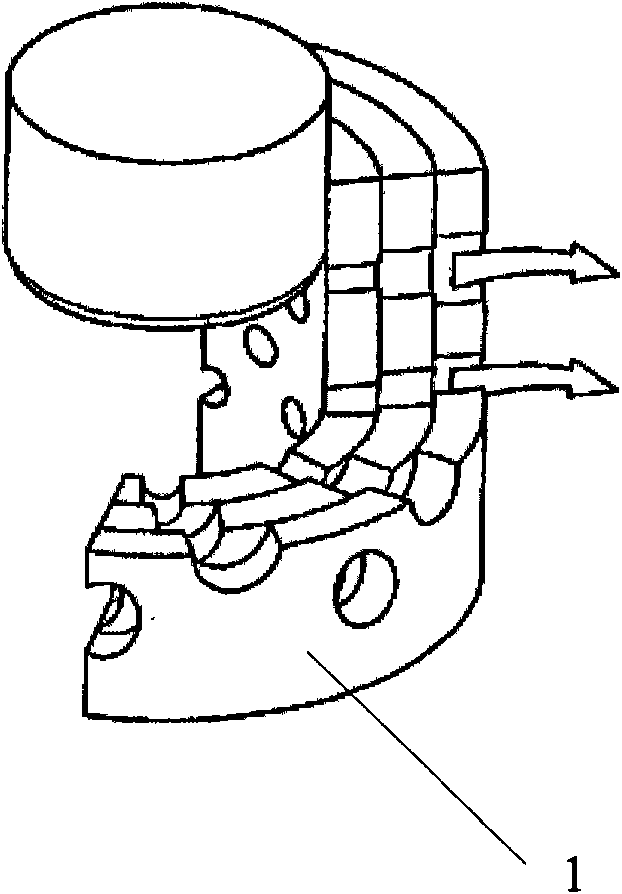

Labyrinth type regulating valve pressure reducing device

ActiveCN102128308AEasy to adjustAnti-scourValve members for absorbing fluid energyFluid controlHigh pressure

The invention relates to the technical field of control over fluids with high pressure differences, in particular to a labyrinth type regulating valve pressure reducing device. The labyrinth type regulating valve pressure reducing device comprises a valve seat, a valve core and a sleeve, wherein the valve core is positioned inside the valve seat; and a plurality of grooves are formed on the ring surface of a valve core body in the axial direction and are provided with at least one bent part. In the labyrinth type regulating valve pressure reducing device provided by the invention, a ring surface axial groove is formed on the surface of the valve core body for throttling, so that the flow can be accurately regulated, and the effects of resisting washing and steam corrosion and reducing noise can be achieved; and by the device, the processing is convenient, design requirements are easy to meet and the cost can be saved.

Owner:SUZHOU DELAN ENERGY TECH

Automobile combined rear lamp structure

ActiveCN101776239BGuaranteed sealing performanceEasy to weldOptical signallingLight fasteningsEngineeringSignal lamp

The invention discloses an automobile combined rear lamp structure, which comprises a lamp housing, a brake lamp / rear position lamp, a rear steering signal lamp and a rear fog lamp / backup lamp, wherein the brake lamp / rear position lamp, the rear steering signal lamp and the rear fog lamp / backup lamp are arranged on the lamp housing. The invention is characterized in that a welded limiting rib is arranged on the right side of a lens, the welded limiting rib protrudes upward, the vertical section of the welded limiting rib is approximately trapezoidal, and the welded limiting rib is fixedly connected with a small limiting boss arranged on the right side of the lamp housing; a primary positioning pin is arranged at the upper part on the right side behind the lamp housing and a secondary positioning pin is arranged at the lower part on the right side behind the lamp housing; a primary positioning hole and a second positioning hole are arranged on a rail lamp reinforcement, and the primarypositioning pin and the secondary positioning pin arranged behind the lamp housing are respectively matched with the primary positioning hole and the secondary positioning hole. The invention has theadvantages that the welding is firm, water is not apt to enter and the service life is long; and the positioning is accurate and the installation is stable.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Pedal feel simulator for vehicle and vehicle having same

ActiveCN110027525BGood braking feelReasonable brake feelBraking action transmissionFoot actuated initiationsDriver/operatorSimulation

The invention discloses a pedal feel simulator for a vehicle and a vehicle having the same. The vehicle includes a pedal, the pedal feel simulator includes a casing, a linear motor, a first elastic member and a second elastic member, and the linear motor includes a motor primary, The motor secondary and the motor push rod, the motor secondary cooperates with the motor primary so that the motor secondary can move axially relative to the motor primary, the motor secondary drives the motor push rod to move synchronously, and the first end of the motor push rod protrudes out of the casing to fit It is connected with the pedal; the two ends of the first elastic part are matched with the inner wall of the shell and the second end of the motor push rod respectively; the second elastic part and the first elastic part are located on both sides of the primary axial direction of the motor, and the The two ends are fitted on the motor push rod and the motor primary respectively. According to the pedal feeling simulator for vehicles of the present invention, the response speed is fast, the braking effect is good, and at the same time, the driver can be provided with good "braking feeling", especially pedal braking feeling.

Owner:BYD CO LTD

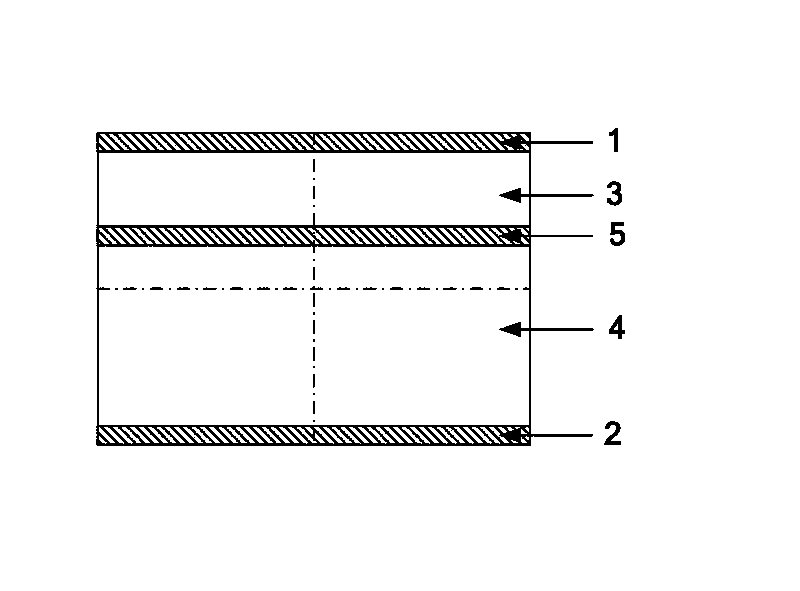

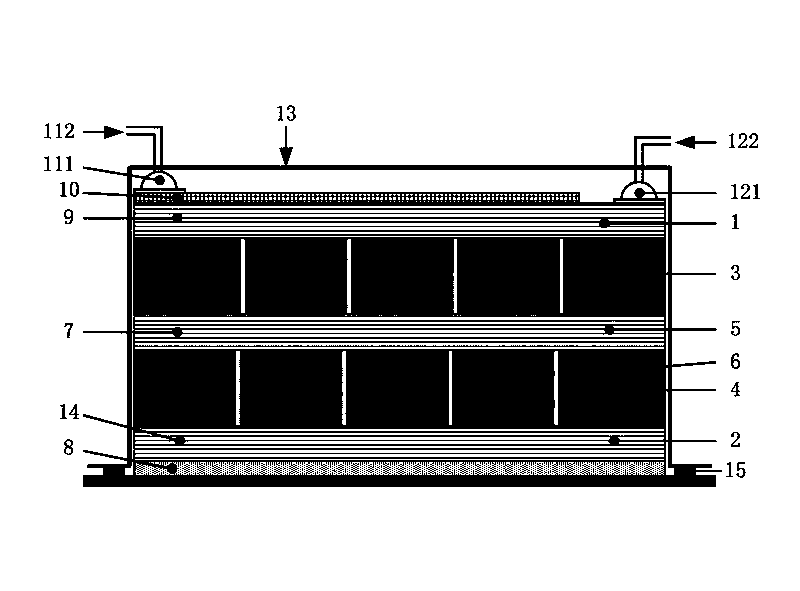

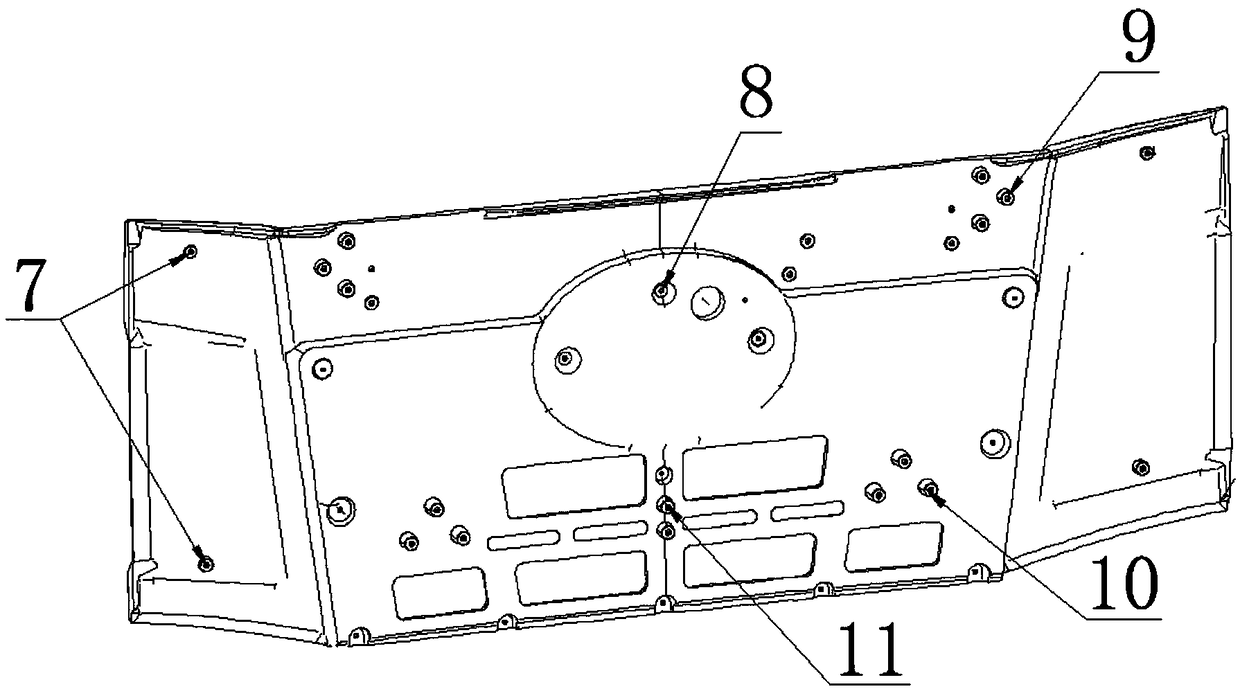

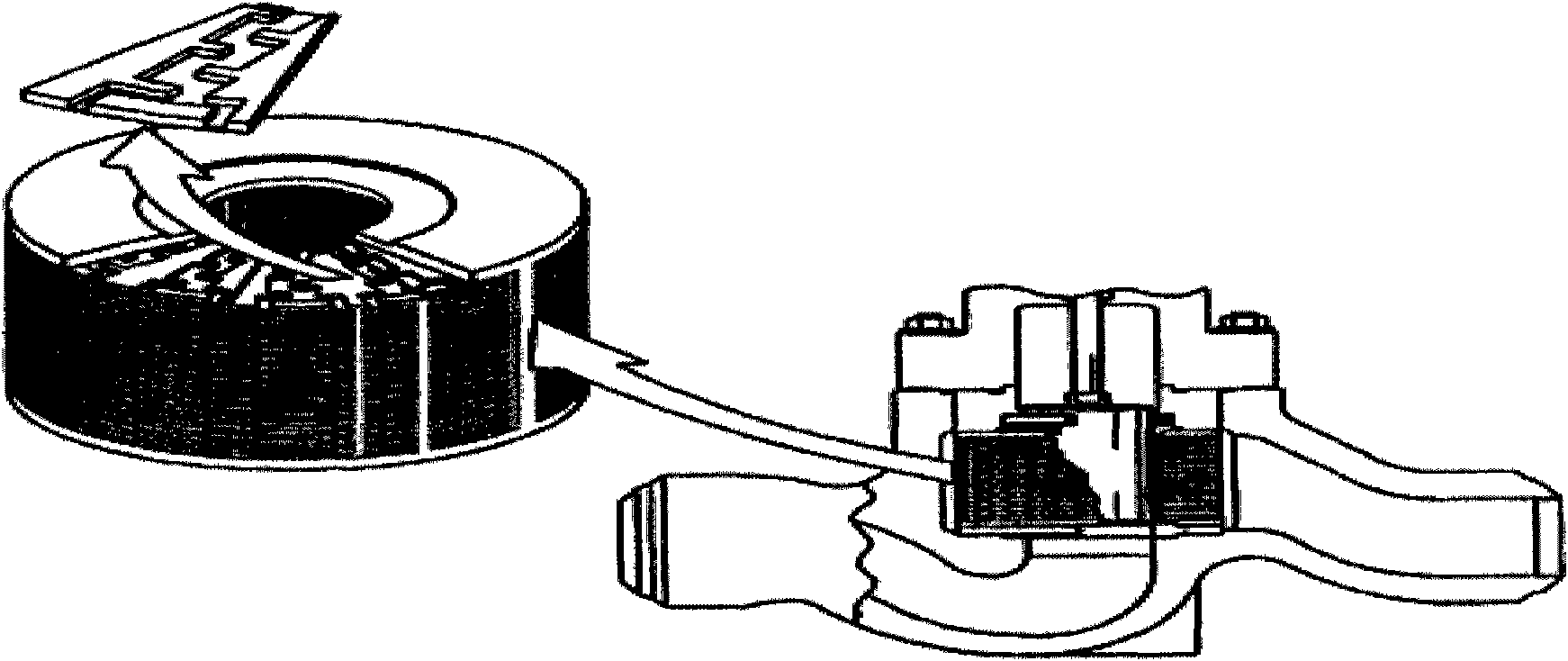

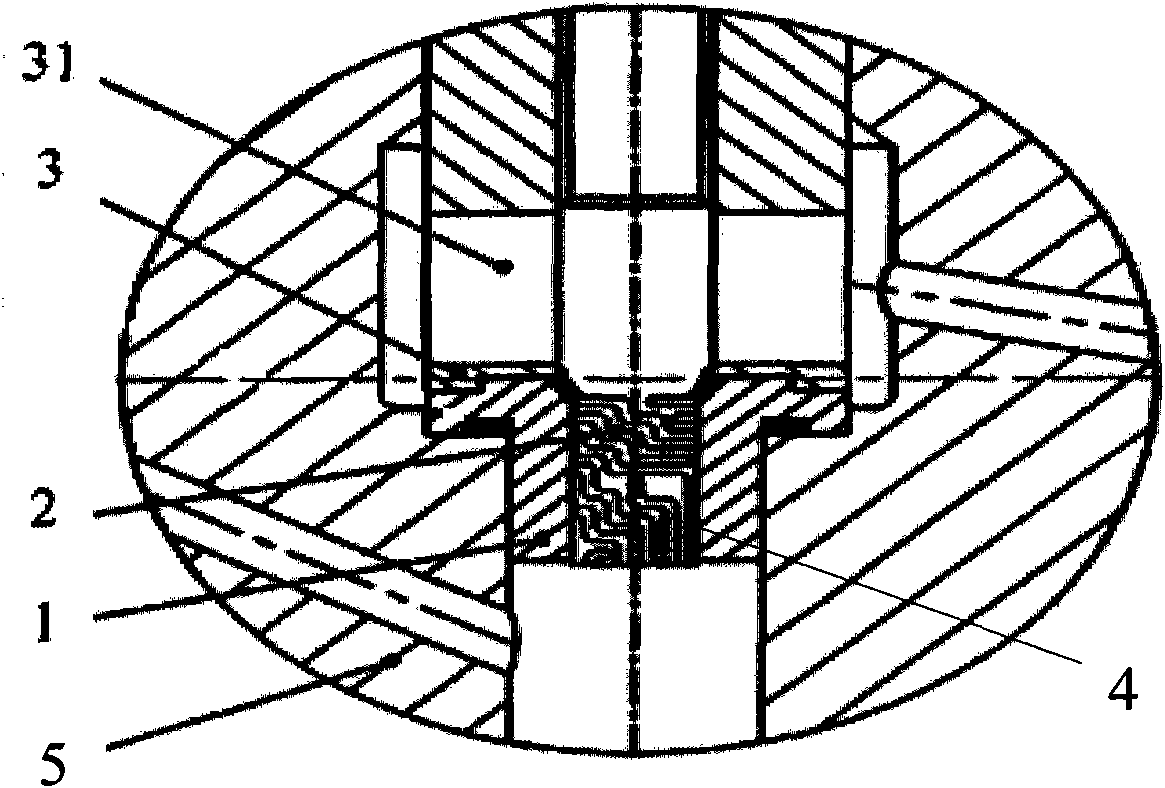

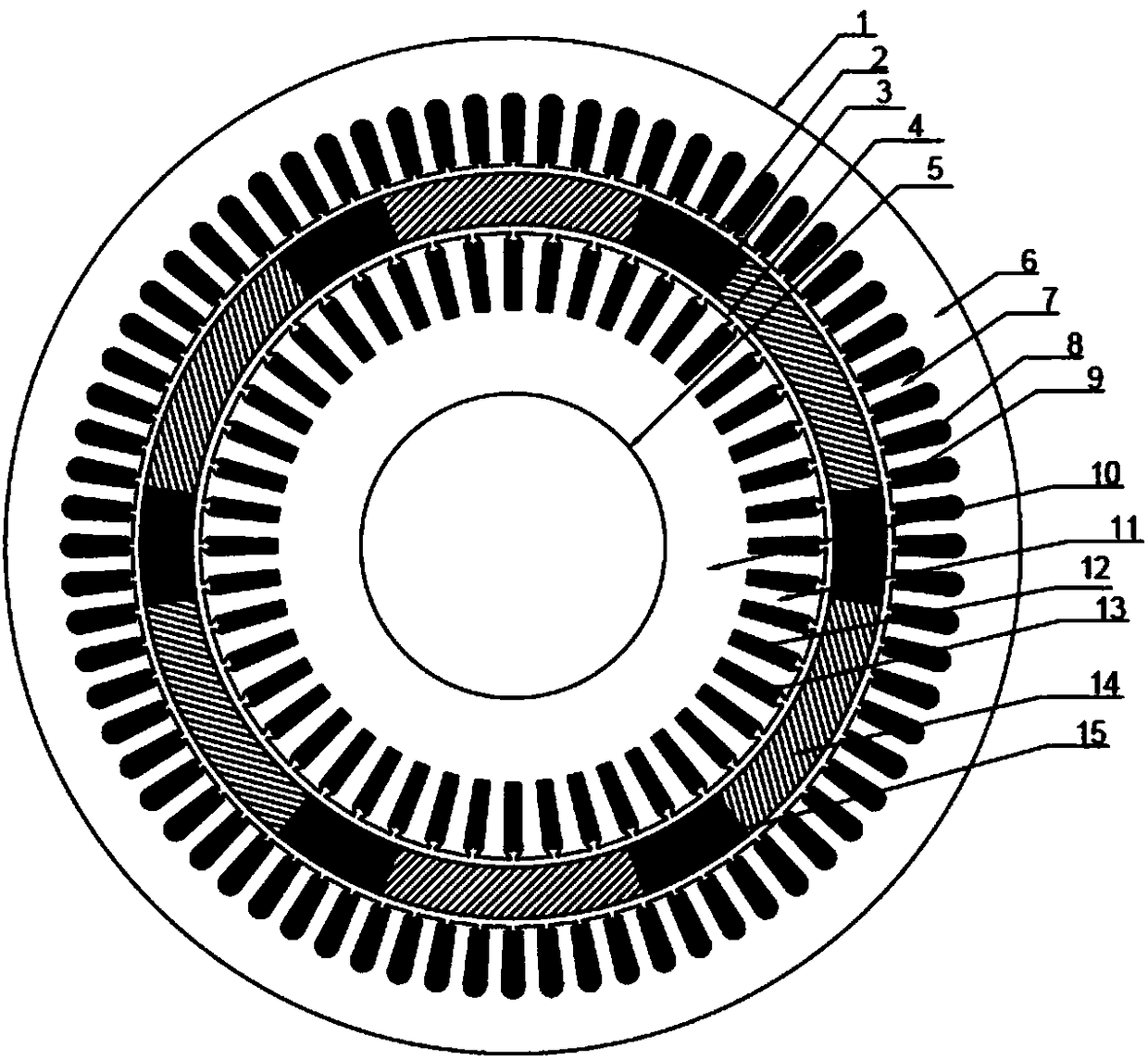

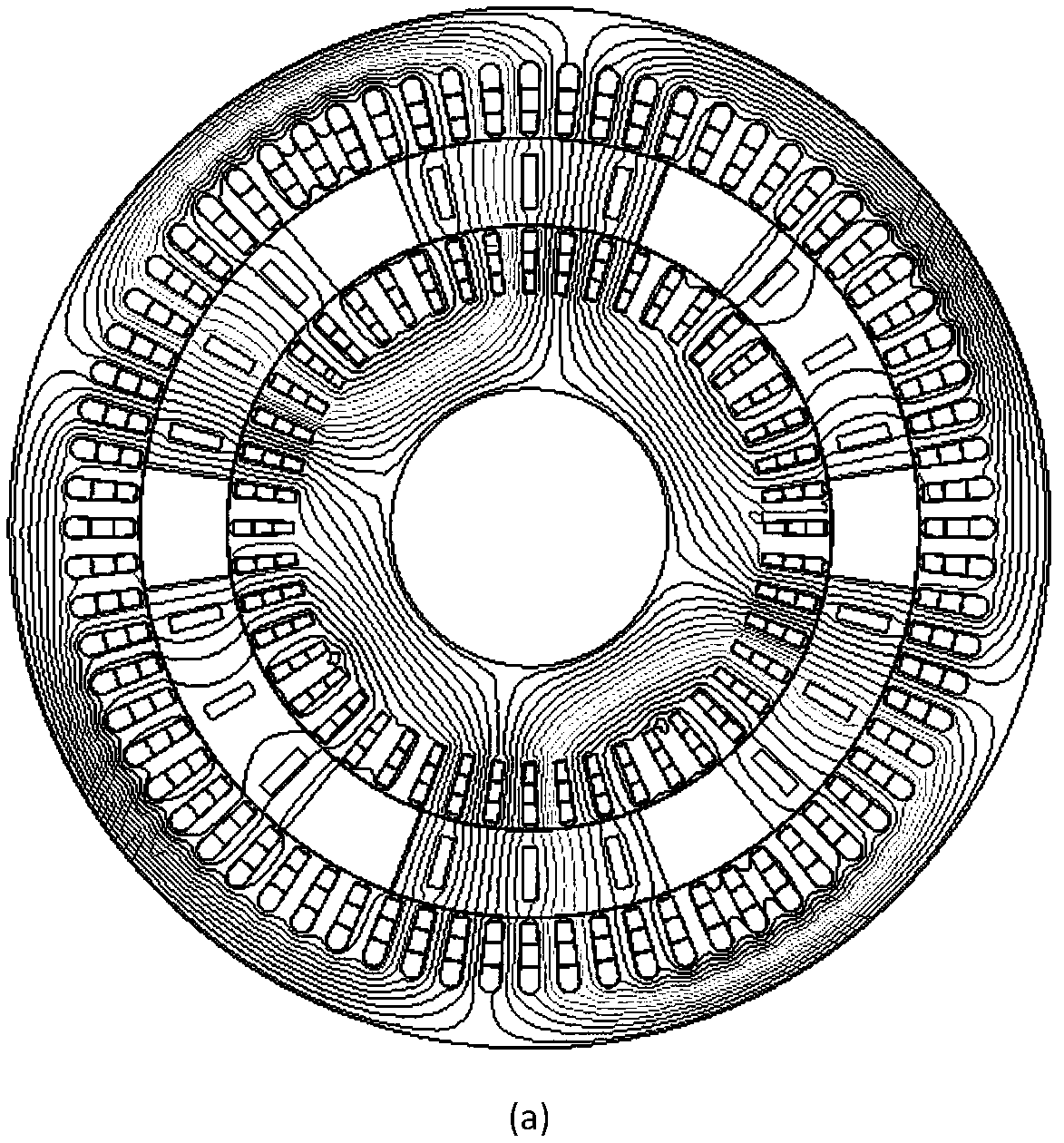

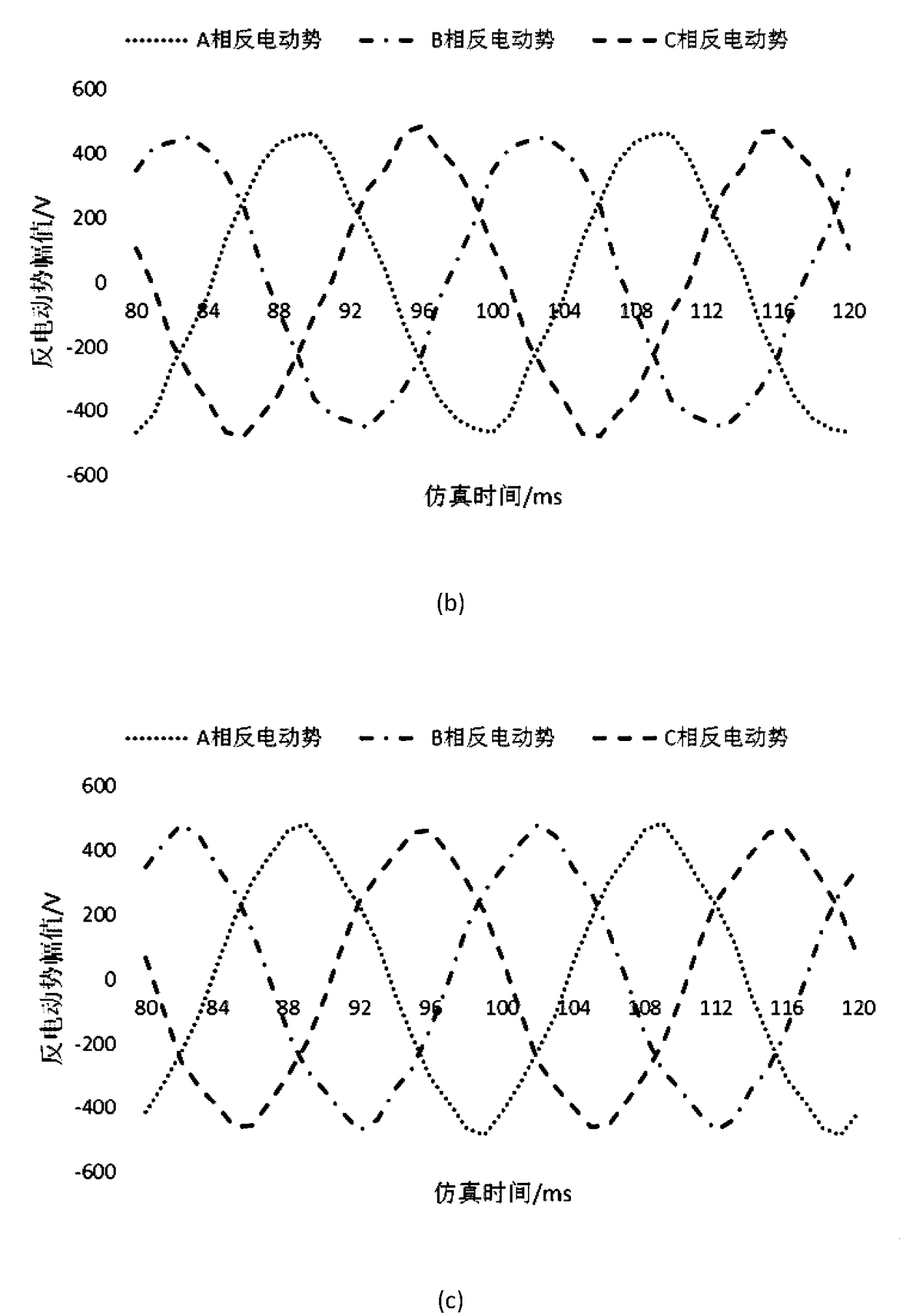

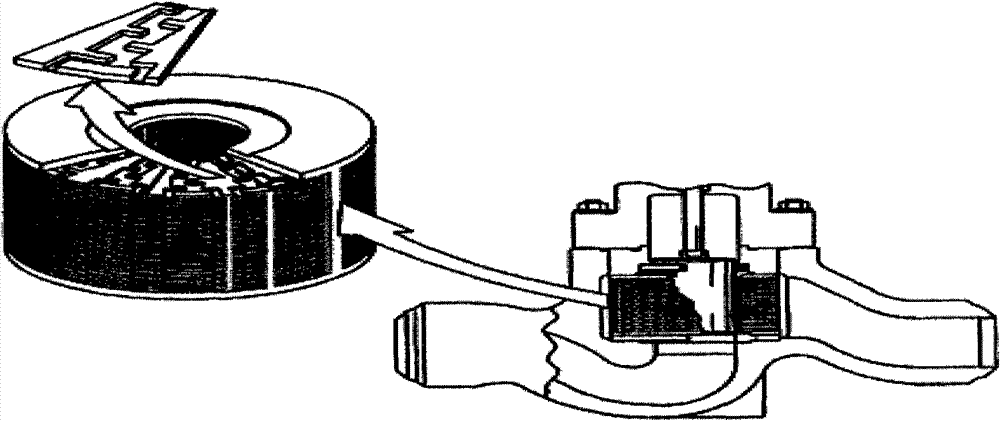

Reluctance Rotor Dual Stator Four Electrical Ports Brushless Double-fed Motor

ActiveCN106451970BImprove power densityImprove reliabilityMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineDoubly fed electric machine

The invention provides a four-electrical port brushless double-fed motor with a reluctance rotor and double stators. The motor comprises two stators and the reluctance rotor which are an outer stator (1), an inner stator (5) and the reluctance rotor (3) and concentrically arranged from outside to inside; an inner air gap (2) is arranged between the inner stator (5) and the rotor (3); an outer air gap (4) is arranged between the outer stator (1) and the rotor (3); the outer stator (1) comprises an outer stator yoke (6), outer stator teeth (7), an outer power winding (8) and an outer control winding (9); the inner stator (5) comprises an inner stator yoke (10), inner stator teeth (11), an inner power winding (12) and an inner control winding (13); the outer control winding (9) of the outer stator (1) and the inner power winding (12) of the inner stator (5) form a work group; the outer power winding (8) of the outer stator (1) and the inner control winding (13) of the inner stator (5) form another work group; and the rotor (3) comprises magnetic conductive blocks (14) and non-magnetic conductive blocks (15) which are uniformly distributed along the circumference.

Owner:SOUTHEAST UNIV

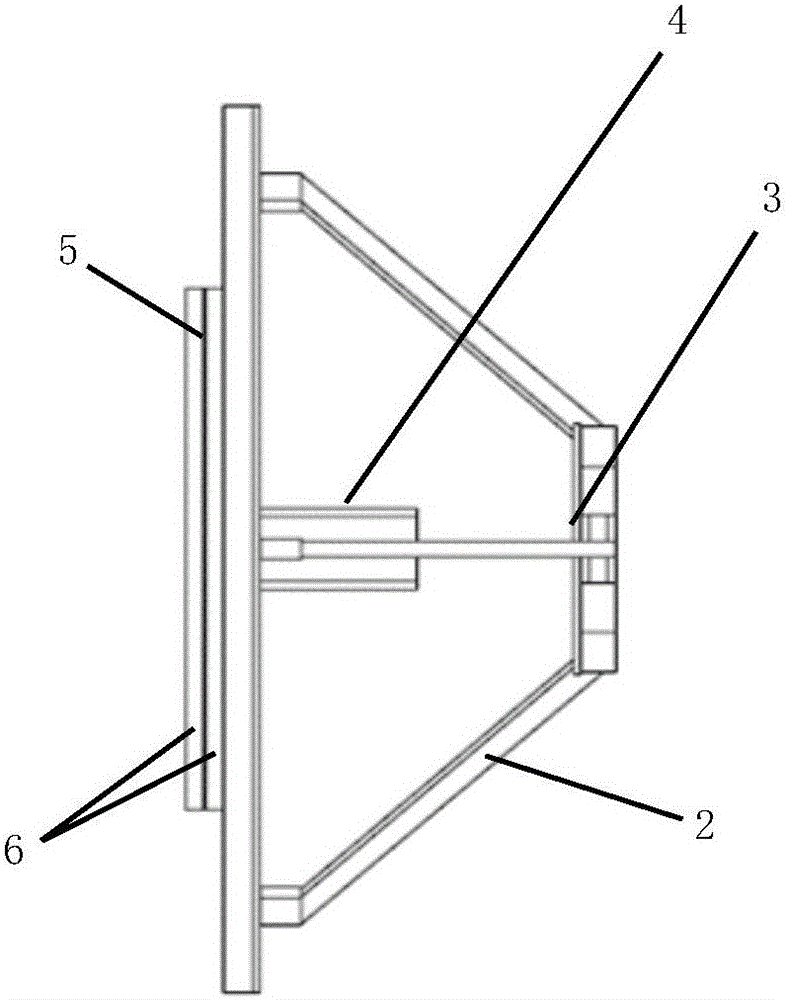

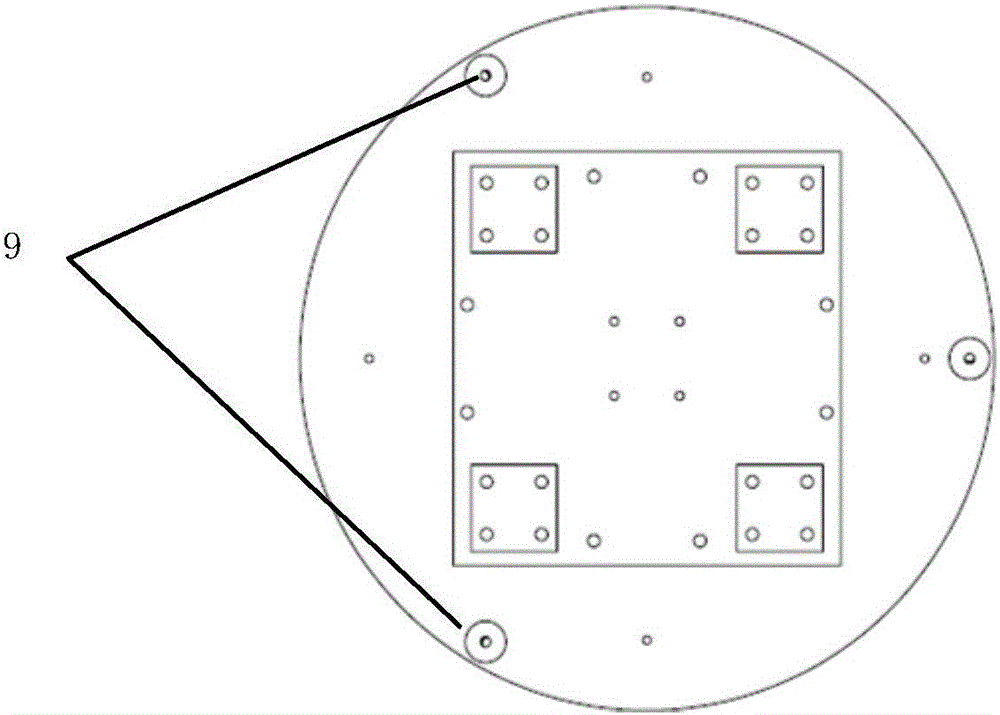

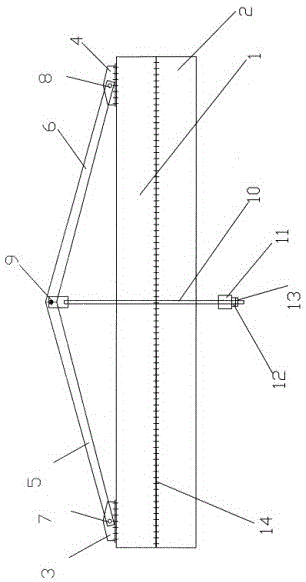

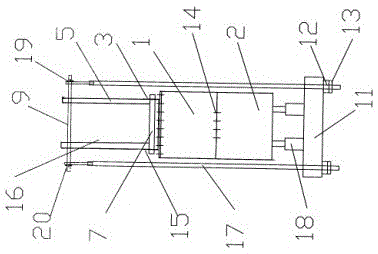

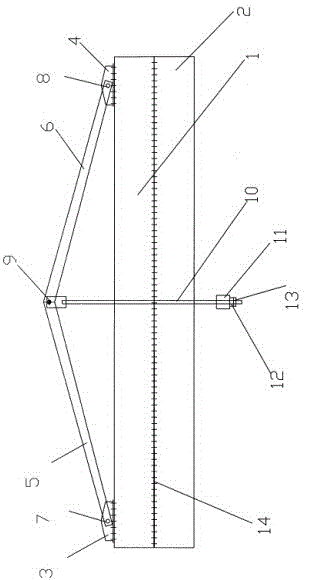

Mounting device for laminated beams of main girder

ActiveCN105066100AOvercoming Process DefectsControl installation qualityBoiler supporting/setting arrangementsEngineeringLaminated beam

The invention discloses a mounting device for laminated beams of a main girder, and solves the technical problem of clearance leakage in connection of upper and lower laminated beams, which possibly causes joint gaping on the upper and the lower laminated beams. The mounting device comprises an upper laminated beam (1) arranged on a lower laminated beam (2), two left connecting frames are fixedly arranged at the left end of the upper laminated beam (1), two right connecting frames are fixedly arranged at the right end of the upper laminated beam (1), the other end of a left front frame girder (5) and the other end of a right front frame girder (6) are hinged together through a top connecting pin (9), the upper end of a front suspender (10) is connected to the front end of the top connecting pin (9), the upper end of a rear suspender (17) is connected to the rear end of the top connecting pin (9), a horizontal supporting beam (11) is connected between the front suspender (10) and the rear suspender (17), a jack (18) is arranged on the horizontal supporting beam (11), and the upper end of the jack (18) is connected to the lower bottom surface of the lower laminated beam (2) in a propping manner. The mounting device provided by the invention ensures entire quality of boiler installation.

Owner:SHANXI ELECTRIC POWER CONSTR CO LTD CEEC

Labyrinth type regulating valve pressure reducing device

ActiveCN102128308BEasy to adjustAnti-scourValve members for absorbing fluid energyFluid controlEngineering

The invention relates to the technical field of control over fluids with high pressure differences, in particular to a labyrinth type regulating valve pressure reducing device. The labyrinth type regulating valve pressure reducing device comprises a valve seat, a valve core and a sleeve, wherein the valve core is positioned inside the valve seat; and a plurality of grooves are formed on the ring surface of a valve core body in the axial direction and are provided with at least one bent part. In the labyrinth type regulating valve pressure reducing device provided by the invention, a ring surface axial groove is formed on the surface of the valve core body for throttling, so that the flow can be accurately regulated, and the effects of resisting washing and steam corrosion and reducing noise can be achieved; and by the device, the processing is convenient, design requirements are easy to meet and the cost can be saved.

Owner:SUZHOU DELAN ENERGY TECH

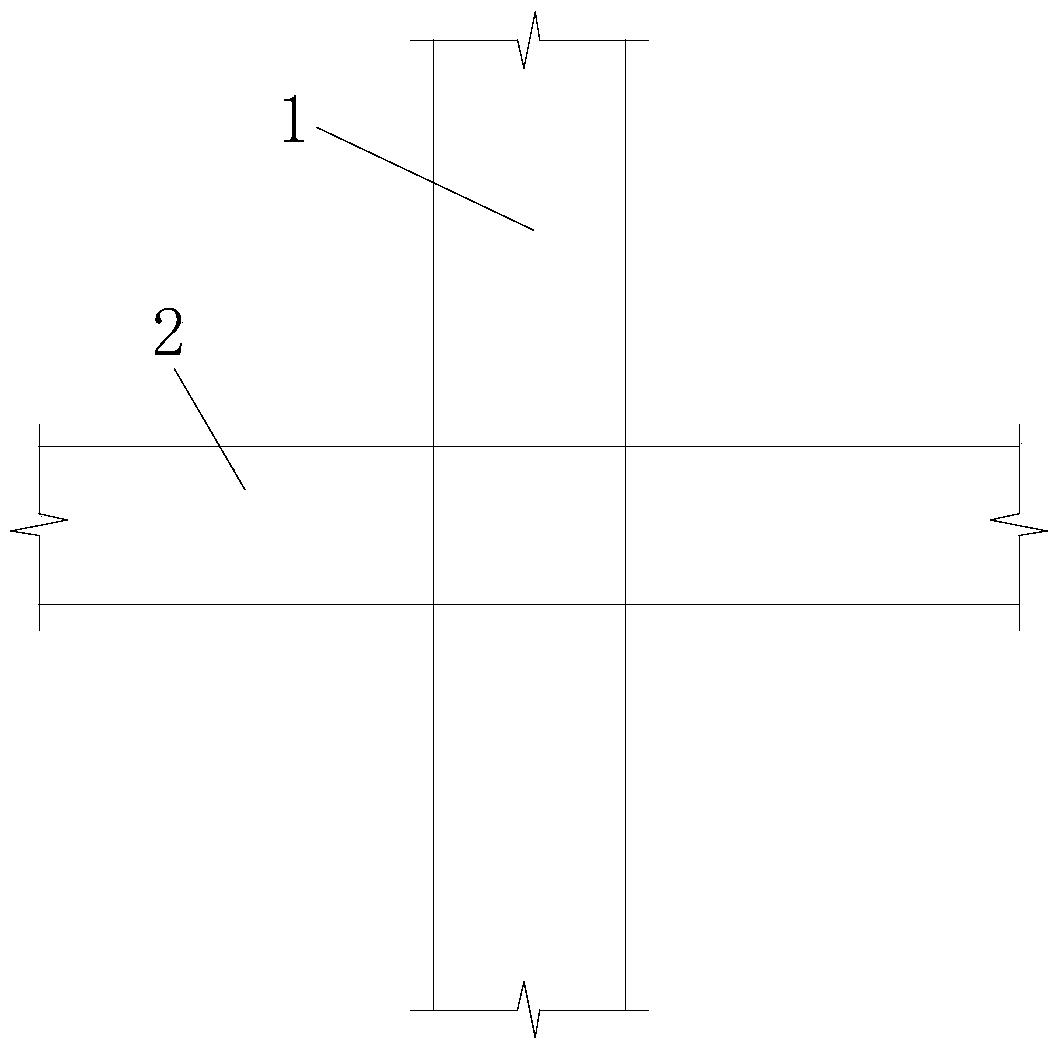

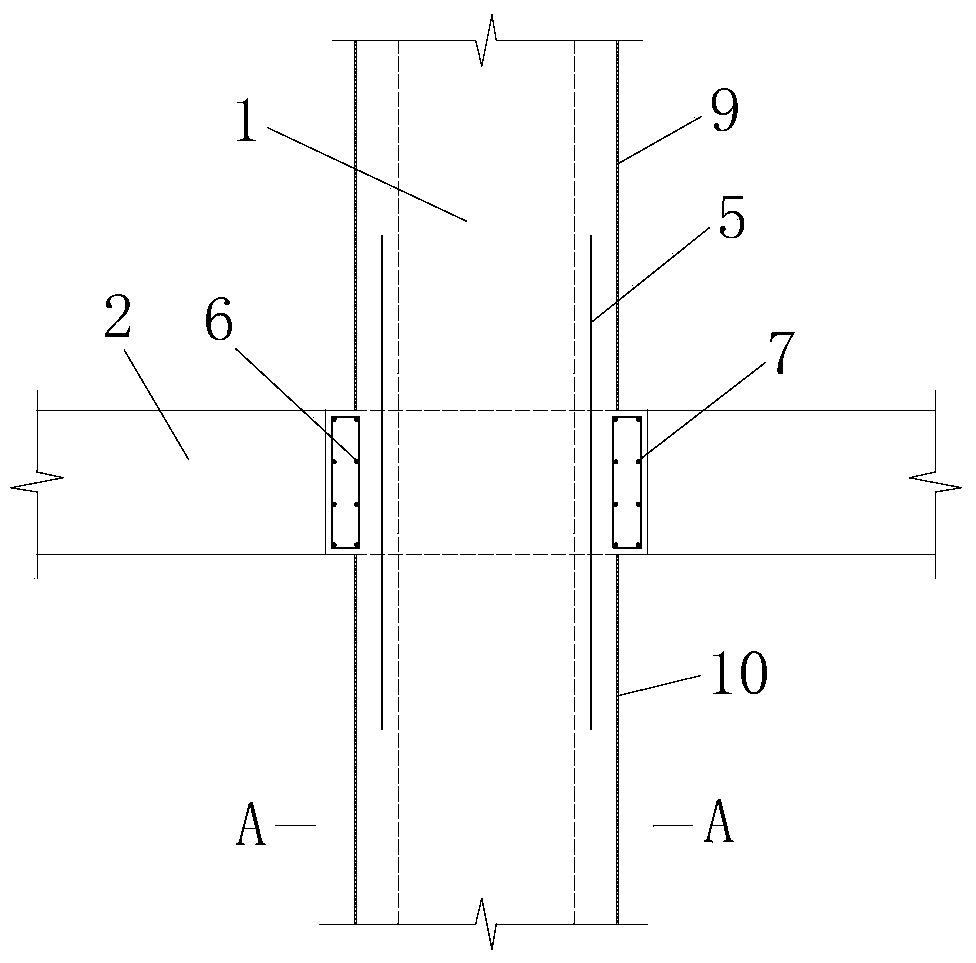

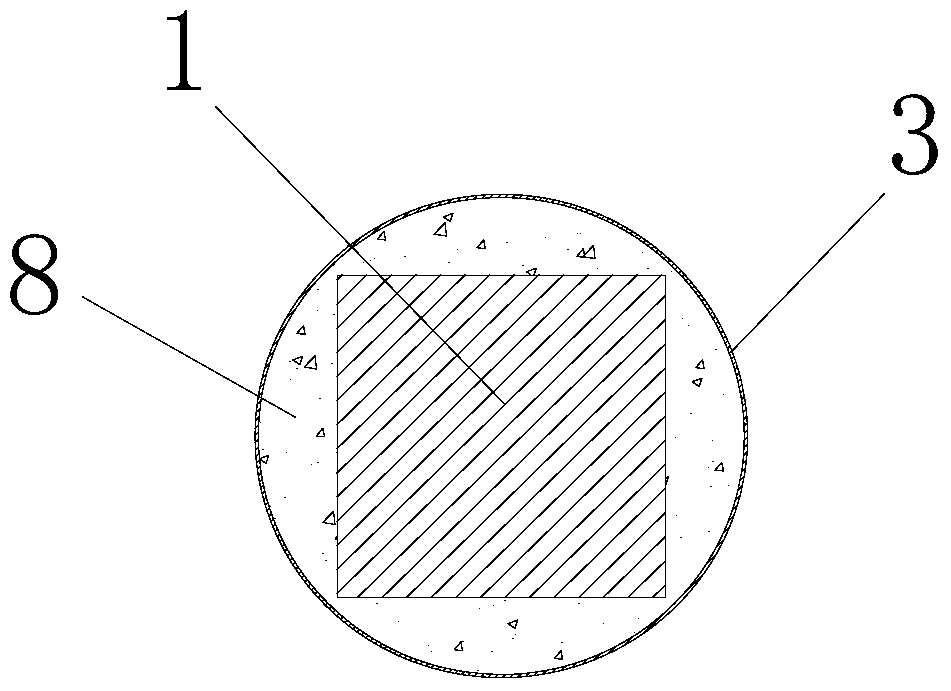

A frame beam-column joint reinforcement structure and its construction method

ActiveCN105239676BIncreased shear capacityIncrease stiffnessBuilding repairsBuilding material handlingShear capacityBeam column

Owner:SOUTH CHINA UNIV OF TECH

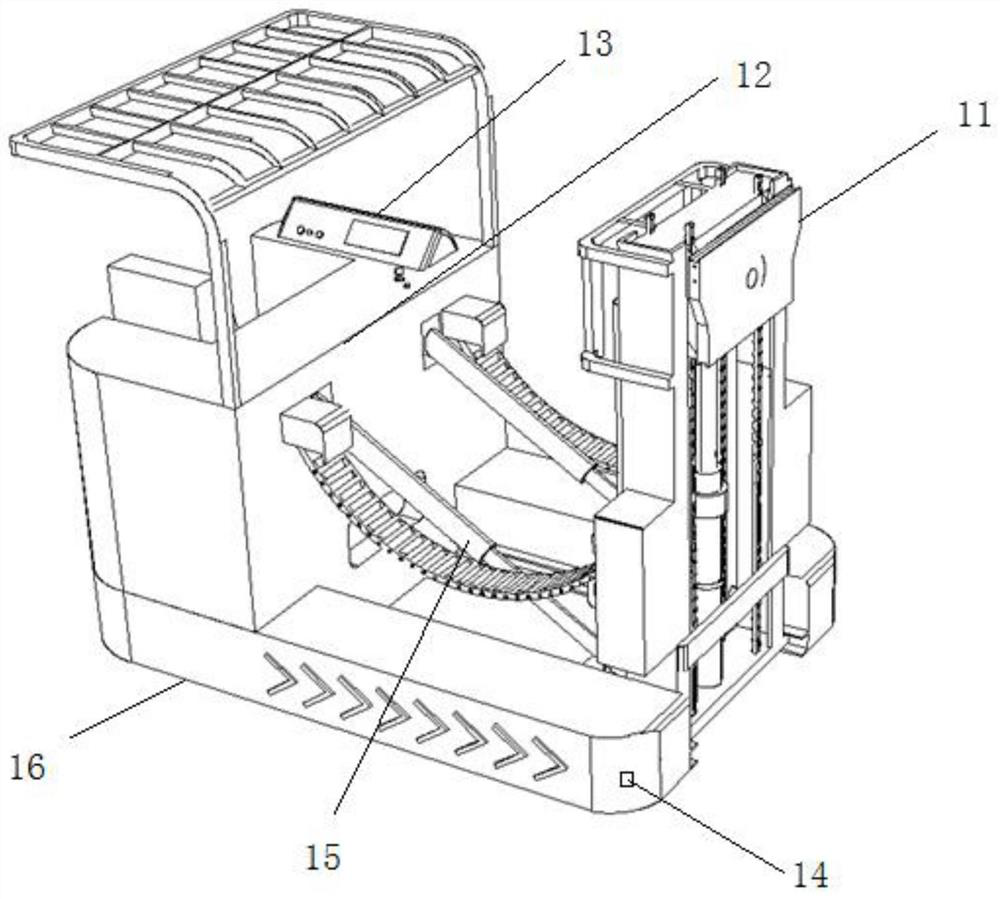

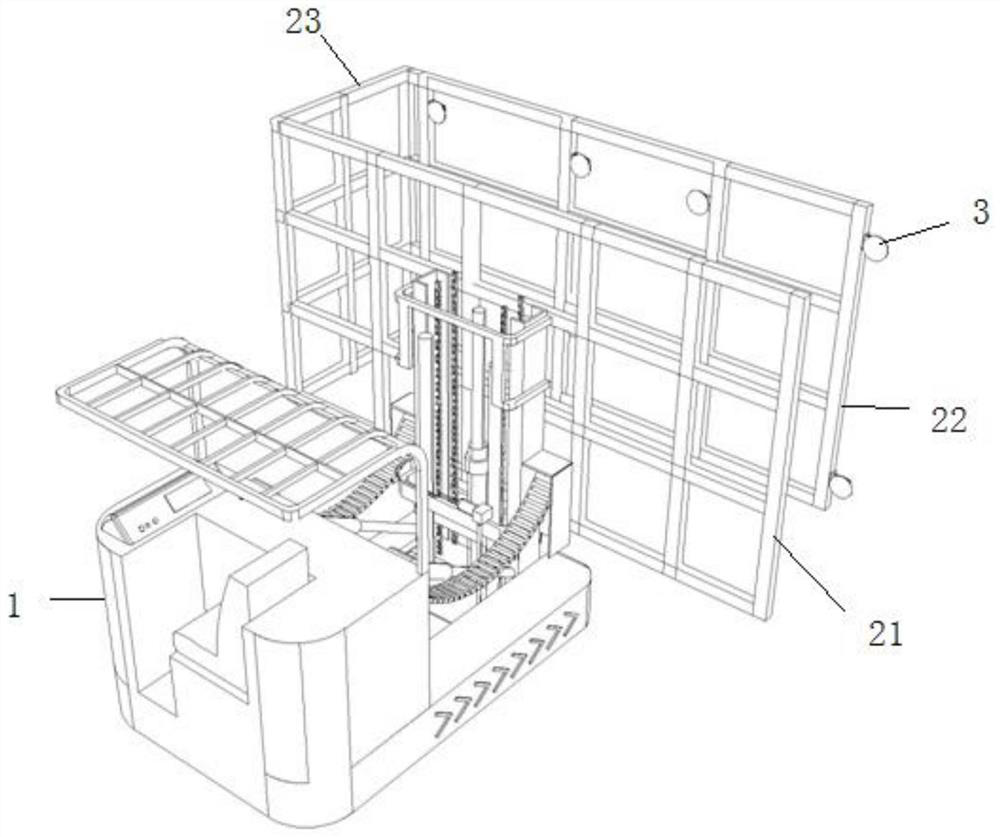

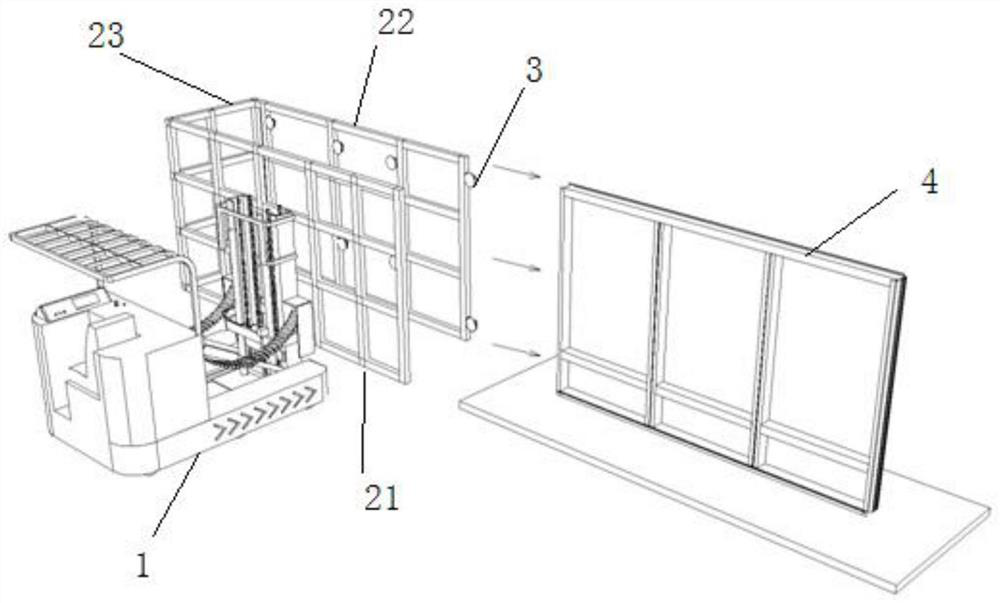

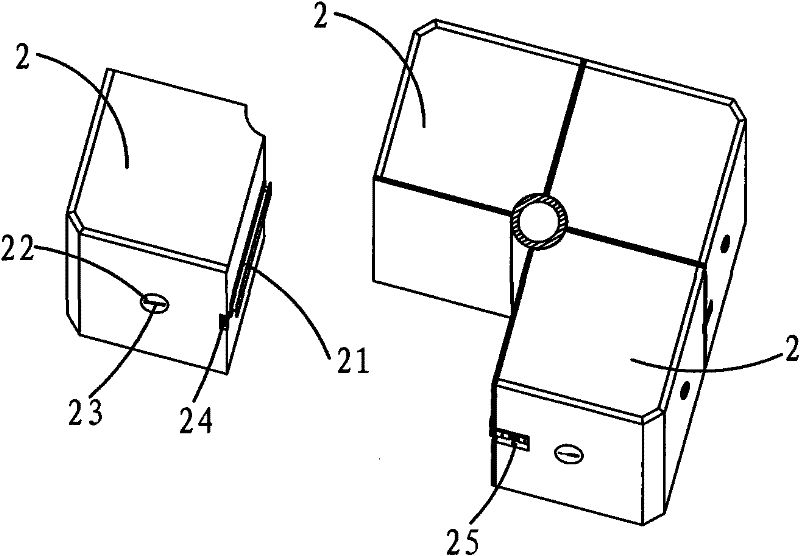

Mounting device for unit window with stand column module

PendingCN112177279AShorten the construction periodInstallation control accuracy is easy to controlBuilding constructionsStructural engineeringMechanical engineering

The invention provides a mounting device for a unit window with a stand column module. The mounting device comprises a mobile robot, a sucker frame, glass suckers and a unit window fixing device, wherein the mobile robot comprises a lifting system; the sucker frame comprises a first plane, a second plane and a third plane, the first plane, the second plane and the third plane are connected to forma C shape, the first plane is connected with the lifting system, and the second plane is far away from the lifting system; the glass suckers are fixed on the second plane, and the glass suckers are used for sucking the glass of the unit window; and the unit window fixing device is arranged on a main body structure of the to-be-installed unit window. Indoor installation of the robot is not affected by weather at all, and the construction period can be effectively shortened; the robot is installed indoors, and the situation that construction is stopped when it is dark does not exist; and the robot installation control precision is easy to control, the installation precision is higher than manual installation precision, and the design requirement is easier to meet.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Freely combined diamond die with fixed bracket

ActiveCN102051976BEasy to fixImprove construction efficiencyBuilding componentsForms/shuttering/falseworksReinforced concreteEngineering

Owner:林荣

Pedal-feeling simulator for vehicle and vehicle with pedal-feeling simulator

ActiveCN110027525AGood braking feelReasonable brake feelBraking action transmissionFoot actuated initiationsLinear motorFootplate

The invention discloses a pedal-feeling simulator for a vehicle and the vehicle with the pedal-feeling simulator. The vehicle comprises a pedal, and the pedal-feeling simulator comprises a shell, a linear motor, a first elastic part and a second electric part; and the linear motor comprises a motor primary part, a motor secondary part and a motor push rod, the motor secondary part is matched withthe motor primary part so that the motor secondary part can axially move relative to the motor primary part, the motor secondary part drives the motor push rod to move synchronously, the first end ofthe motor push rod extends out of the shell to be suitable for being connected with the pedal, the two ends of the first elastic part are matched with the inner wall of the shell and the second end ofthe motor push rod correspondingly, the second elastic part and the first elastic part are located on the two axial sides of the motor primary part, and the two ends of the second elastic part are matched with the motor pushing rod and the motor primary part. The pedal-feeling simulator for the vehicle is high in response speed, has the good braking effect, and meanwhile can provide the good 'braking feeling', especially a pedal braking feeling, for a driver.

Owner:BYD CO LTD

A connection structure of an all-composite ground-effect wing ship

ActiveCN109229373BImproved ability to withstand concentrated loadsImprove stabilityFuselagesSeaplanesEpoxyStructural engineering

The invention relates to a connecting structure of an all-composite winged ship, each component of the Wing-in-Ground effect ship is provided with the same connecting part, A PVC structural foam corematerial, A FRP surface plate is arrange on that upper and lower surface of the foam core material of the PVC structure, one end of the FRP surface plate is connected with the FRP connection plate, AFRP connection layer plate is provide with a notch in that middle of the joint with the FRP surface plate, A PVC structural foam core material extend into that notch, the FRP connection layer plate isformed into a solid plate structure at one end away from the FRP surface plate, the solid plate structure of the two members to be connected overlaps upwardly and downwardly, A plurality of double-row staggered through holes are arranged at the overlapping position, a metal sleeve liner is bonded with epoxy resin in the through holes, and bolts are installed in the metal sleeve liner. The invention adopts the boss structure respectively, and the split wing box connects the hull with the aft wing and the ground effect wing, the connection is firm, and the manufacturing, disassembly and assembly are convenient, and the utilization rate of the hull space is improved.

Owner:中船重工(海南)飞船发展有限公司

Large slab beam stacking beam installation device

ActiveCN105066100BOvercoming Process DefectsEffective control of installation qualityBoiler supporting/setting arrangementsEngineeringLaminated beam

The invention discloses a large-slab girder stacking beam installation device, which solves the technical problem that the existing upper and lower stacking beams are not tightly connected, which easily leads to joint cracking of the upper and lower stacking beams. The upper stacking beam (1) is arranged on the lower stacking beam (2), two left connecting frames are fixedly arranged at the left end of the upper stacking beam (1), and two right connecting frames are fixedly arranged at the right end of the upper stacking beam (1) , the other end of the left front frame beam (5) is hinged with the other end of the right front frame beam (6) through the top connecting pin (9), and the upper end of the front boom (10) is connected to the front end of the top connecting pin (9) , the upper end of the rear boom (17) is connected to the rear end of the top connecting pin (9), and a horizontal support beam (11) is connected between the front boom (10) and the rear boom (17). A jack (18) is arranged on the beam (11), and the upper end of the jack (18) is connected to the lower bottom surface of the lower stacking beam (2). The invention ensures the overall quality of boiler installation.

Owner:SHANXI ELECTRIC POWER CONSTR CO LTD CEEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com