Pressure Infiltration Forming Method of Latent Composite Radome

A technology of composite materials and molding methods, applied in the direction of the radiation unit cover, etc., can solve the problem of high equipment cost and achieve the goal of manufacturing

The effect of low equipment cost, simple production and easy implementation

Inactive Publication Date: 2013-08-28

NAT UNIV OF DEFENSE TECH +1

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Second, the cover material must have excellent dielectric properties

Moreover, the RTM process requires a special injection machine, and the equipment cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

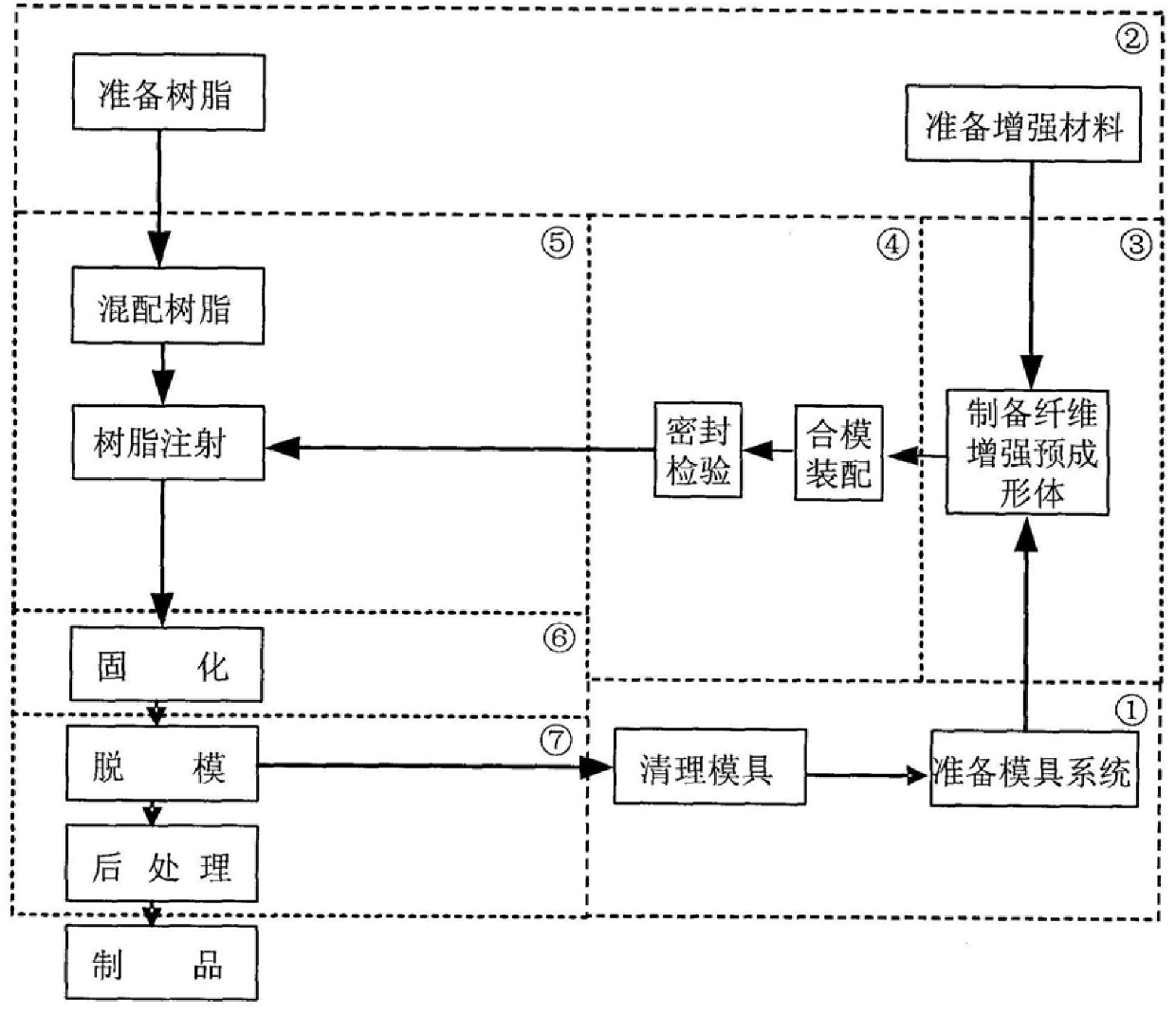

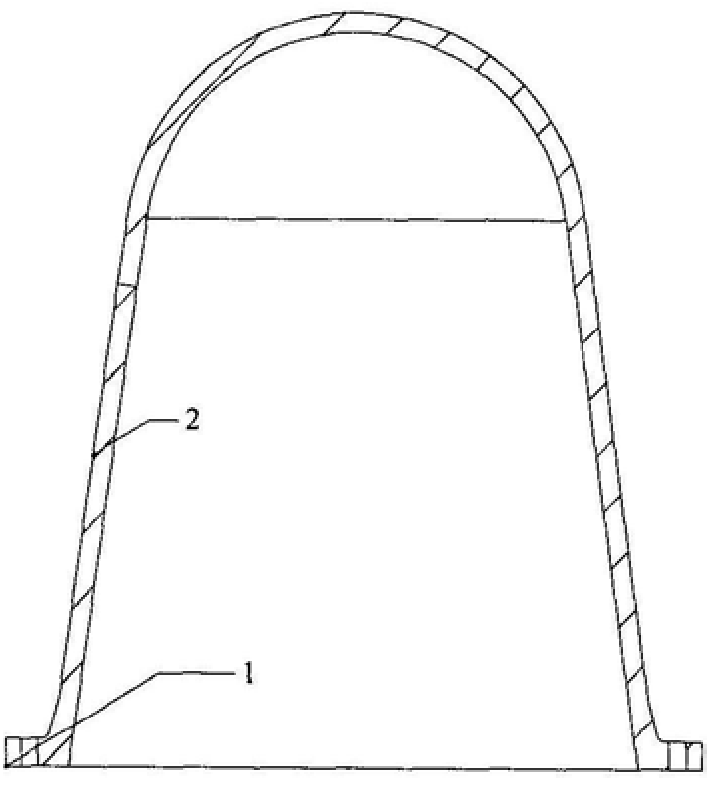

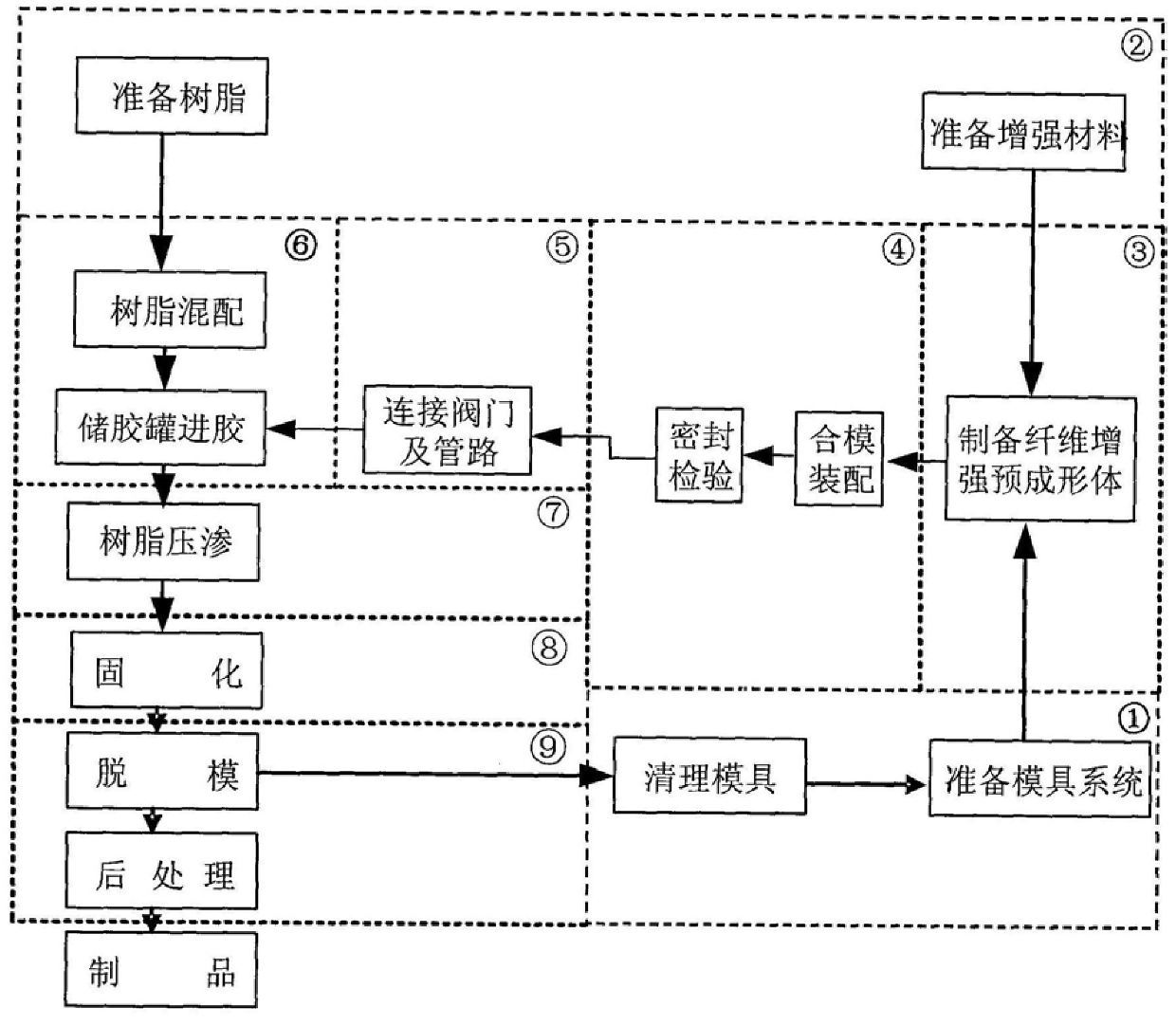

Abstract

The invention discloses a piezo-infiltration molding method for latent composite material radome. The technical problem to be solved is to provide a low-cost overall preparation method for composite material radome, so that the prepared composite material radome has strict dimensions and wall thickness. Uniform, smooth inner and outer surfaces, excellent dielectric properties, and high overall load-bearing performance. The technical solution is to prepare the mold and materials first, then prepare the fiber-reinforced preform, close the mold and seal it, then connect the valve and pipeline, carry out resin mixing, glue storage tank, and then carry out resin pressure infiltration, including normal pressure impregnation. Infiltration and pressure infiltration, and finally curing and demoulding and post-treatment. The preparation of the composite material radome by the present invention is easy to operate and low in cost; it can flexibly adjust the pressurization speed of the resin glue liquid to the mold cavity, and the adjustment range is large, which is especially beneficial to the slow impregnation and integral molding of the composite material radome with a thick-walled structure. .

Description

The pressure infiltration forming method of latent composite material radome Technical field The present invention relates to a kind of preparation method of composite material member, especially a kind of for protecting submarine communication system Integral molding method of composite material radome. Background technique Submarine plays a pivotal role in the modern offensive and defensive system as the important combat power of modern navy. latent The advanced radar countermeasure and reconnaissance equipment equipped on submarines plays an increasingly important role in ensuring the safety of submarine platforms, concealed attacks and intelligence reconnaissance. important role. [0003] The radar antenna-radome system is one of the important hardware facilities of the submarine communication system. The radome is used to withstand deep Seawater pressure, isolated from the seawater environment, ensures that the antenna inside the cover can work normally under ha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C45/14B29C70/48H01Q1/42

Inventor 刘钧曾竟成肖加余卢斌李永林江大志杜刚王春齐邢素丽

Owner NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com