Reluctance Rotor Dual Stator Four Electrical Ports Brushless Double-fed Motor

A doubly-fed motor and double-stator technology, applied in the direction of electrical components, magnetic circuits, electromechanical devices, etc., can solve the problems of motor failure, low motor reliability, and poor fault tolerance, and achieve easy processing and installation, simple and reliable structure, Effect of Reducing Leakage Flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

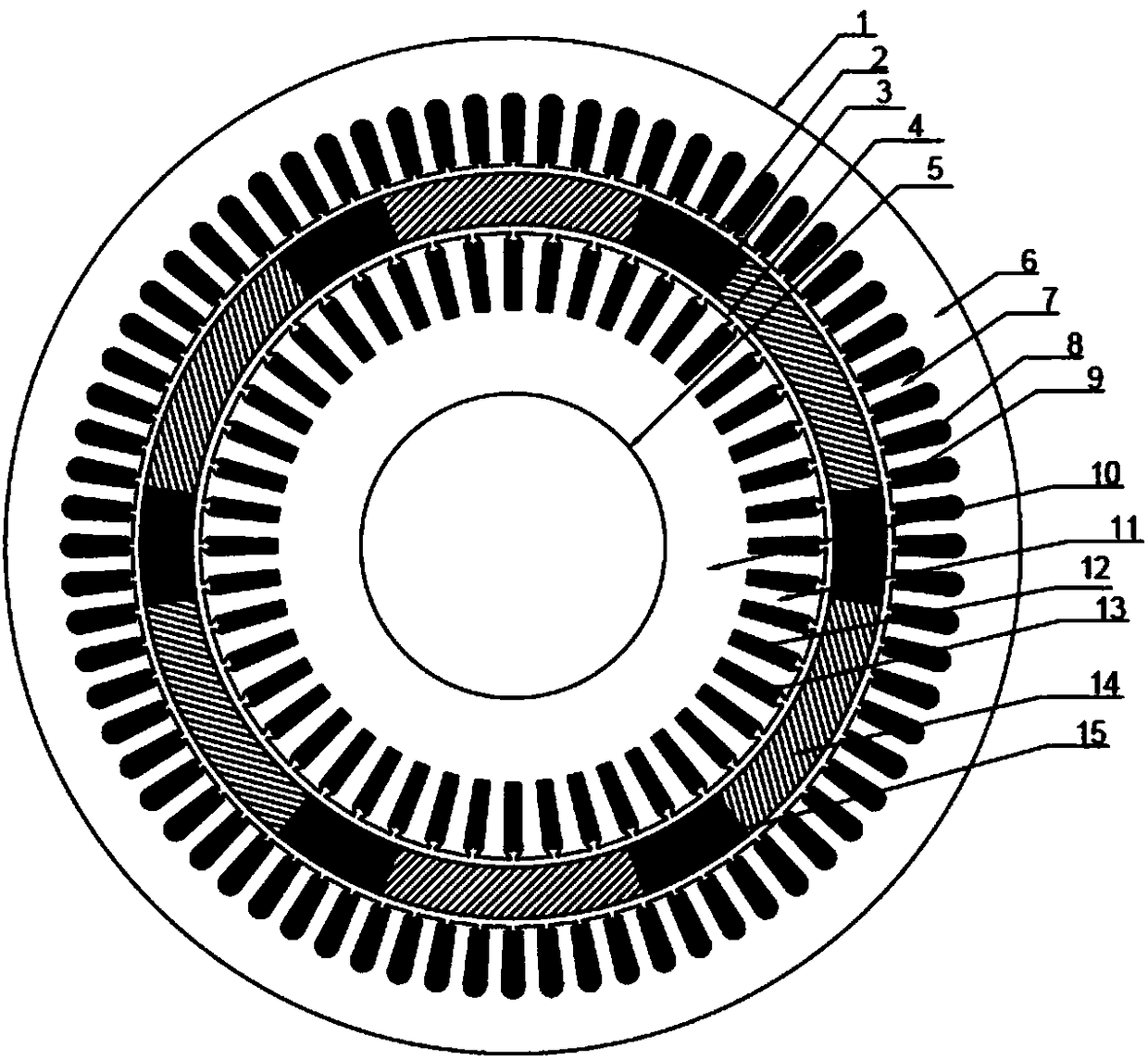

[0027] like figure 1 As shown, the outer stator, the rotor, and the inner stator are concentrically arranged, and from the outside to the inside, they are the outer stator 1, the outer air gap 2, the rotor 3, the inner air gap 4, and the inner stator 5; the outer stator 1 includes the outer stator yoke 6 , outer stator teeth 7, double-layer outer power windings 8 embedded in slots and single-layer outer control windings 9; the inner stator 5 includes inner stator yokes 10, inner stator teeth 11, double-layer inner inner stators embedded in slots A power winding 12 and a single-layer inner control winding 13; the rotor 3 includes magnetically permeable blocks 14 and non-magnetically permeable blocks 15 uniformly distributed along the circumference.

[0028] Reluctance rotor double stator four electrical ports brushless double-fed motor, the outer stator, rotor and inner stator are arranged in sequence from outside to inside, there are air gaps between the inner and outer stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com