Double-screw extruder

A twin-screw extruder and twin-screw technology, applied in the field of extrusion molding, can solve problems such as feeding gaps, and achieve the effect of avoiding loss and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

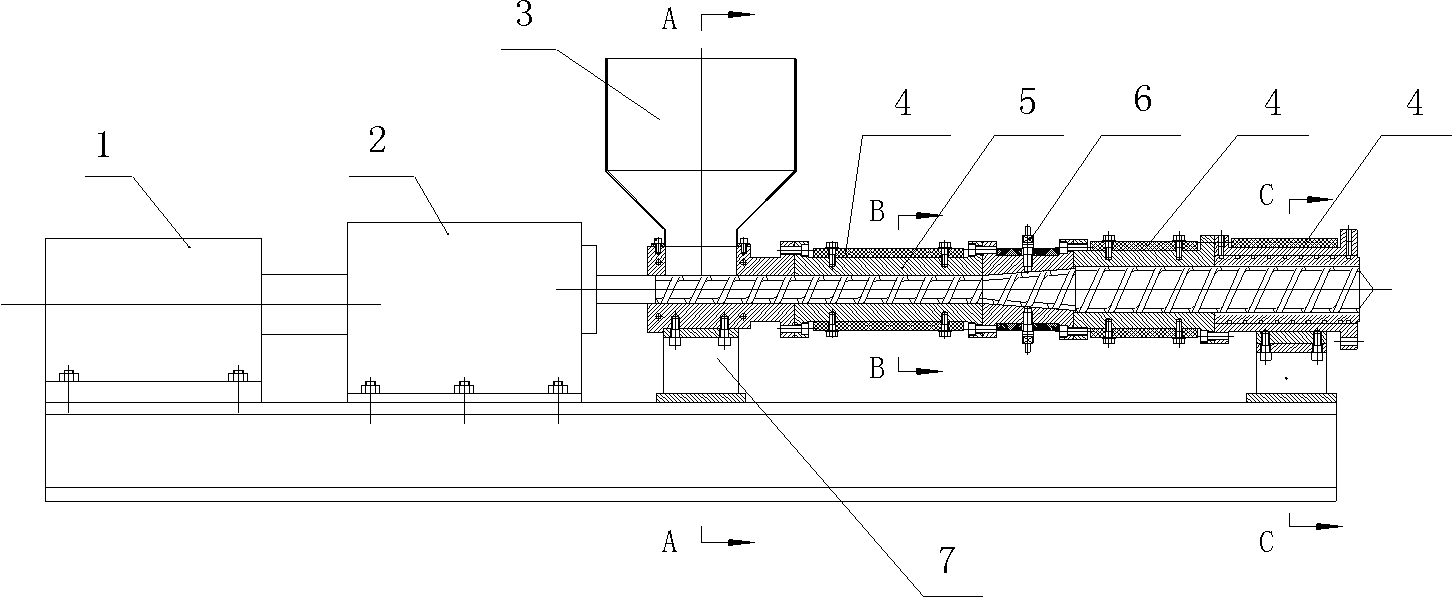

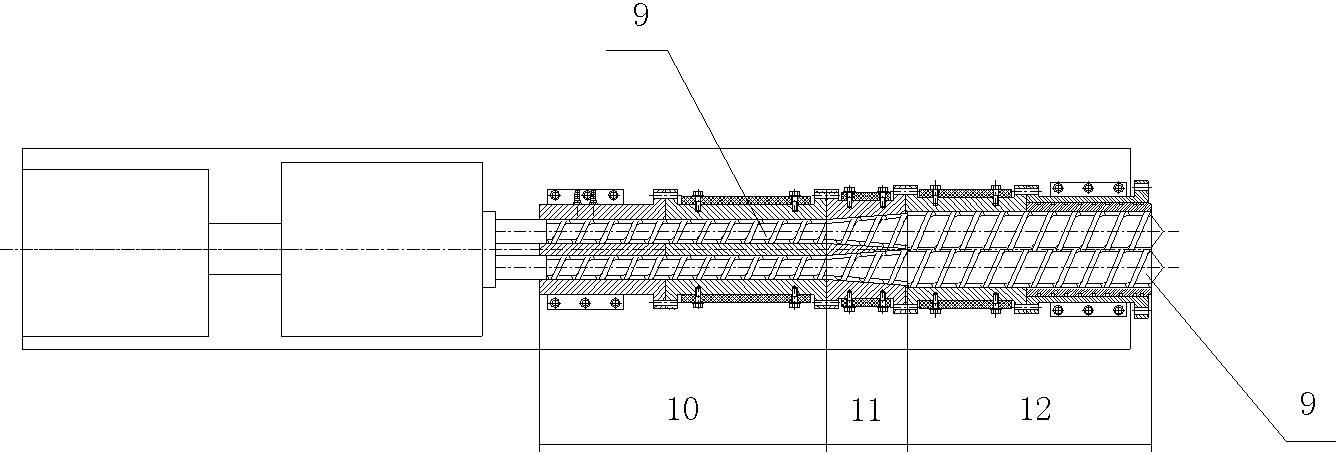

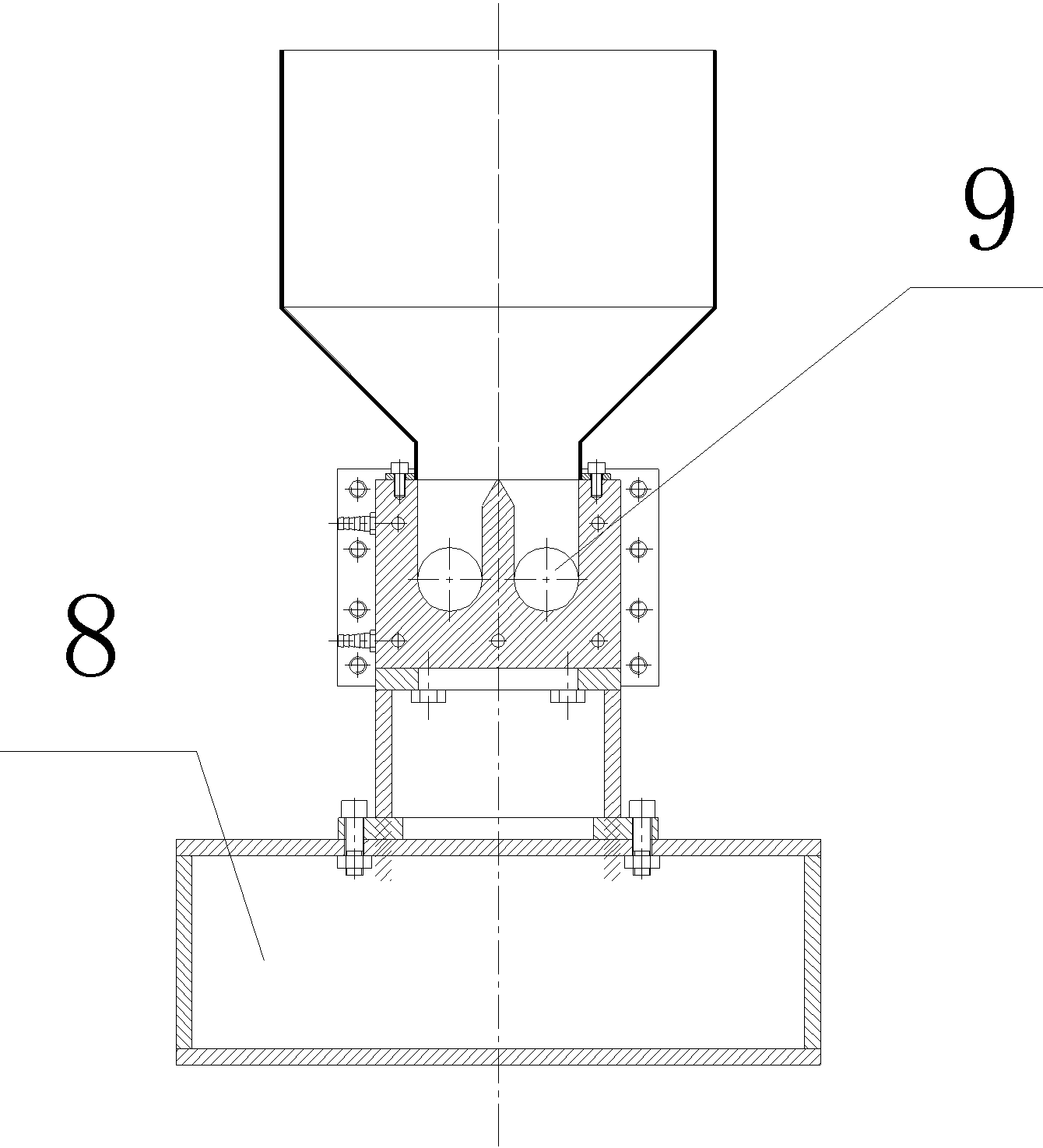

[0023] Such as figure 1 with figure 2 As shown, a twin-screw extruder in this embodiment includes a barrel 5 and a parallel twin-screw 9, and a section inside the barrel 5 is divided into two independent through passages through an interlayer. Both screws 9 are located in the barrel 5, including an independent section 10, a filling section 11 and an engaging section 12 arranged in sequence along the conveying direction of the screws 9 (from left to right). Such as image 3 with Figure 4 As shown, the two screws 9 in the independent section 10 are in a non-engaging state, and the two screws 9 are respectively located in two independent passages through the barrel 5, and an electric heater 4 is provided on the entire section of the barrel. The two rods in the filling section 11 are also in a non-engaging state. The two screw rods 9 are respectively located in the two independent passages of the barrel 5. The injection section is provided with a filler 6, and the outlet of t...

Embodiment 2

[0038] The difference from Example 1 is that the screw 9 in Example 1 is integral; and the screw 9 in Example 2 is combined: the first screw 9 in the independent section 10 is located in the filling section The second screw 9 in 11 is composed of the third screw 9 in the engaging section 12 .

[0039] The advantage of such setting is: when different screw rods 9 can be replaced according to the mixing situation of materials, when the screw rod 9 of the corresponding section is damaged, only the damaged section screw rod 9 needs to be replaced instead of the screw rods 9 of other sections.

Embodiment 3

[0041] The difference from embodiment 1 is that the screw rod 9 in embodiment 2 is a three-stage type, while the screw rod 9 in embodiment 3 is a two-stage type, that is, the first screw rod located in the independent segment 10 and the filling segment 11 A screw 9 and a second screw 9 located in the engaging section 12 are composed.

[0042] Because we found that the independent section 10 and the filling section 11 have many similar features (such as they do not need to be engaged, and they are all located in the two independent passages of the barrel 5), when it is necessary to replace the different screw 9 , the requirements for the independent section 10 and the filling section 11 are also very similar, and can be replaced as a screw 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com