Production method of ceramic tile

A production method and technology for ceramic tiles, which are applied in the production field of ceramic tiles, can solve the problems that the texture is not easy to meet or meet the design requirements, the surface is not smooth and beautiful, and the effect of smooth surface and avoiding cracking can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Now in conjunction with embodiment the present invention is described in further detail:

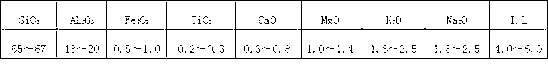

[0010] The present invention includes tile body molding process, drying process, glazing process, firing process, polishing process, and the tile body composition in the tile body molding process is composed of

[0011]

[0012] Composition, glazing process The glazing process is composed of a surface glaze application process and a polishing glaze application process.

[0013] The tile body forming process includes a batching process, a ball milling process, a ceramic slurry drying process, and a tile body pressing molding process. The drying process is to air-dry the tile body in a dry moisture ≤ 0.6% to make it reach 2.0 mPa > dry strength ≥ 1.0mPa; when entering the kiln, the water content of the tile body is < 2%. before entering the glazing process. Edge the tile body first. After the top glaze is applied during the glazing process, a 3D inkjet printer is used to print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com