Tapered pole and production method thereof

A tapered and utility pole technology, applied in building components, building insulation materials, building types, etc., can solve the problems of small elastic modulus, low flexural performance, low production efficiency, etc., to improve flexural strength and improve mechanical performance, the effect of increasing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

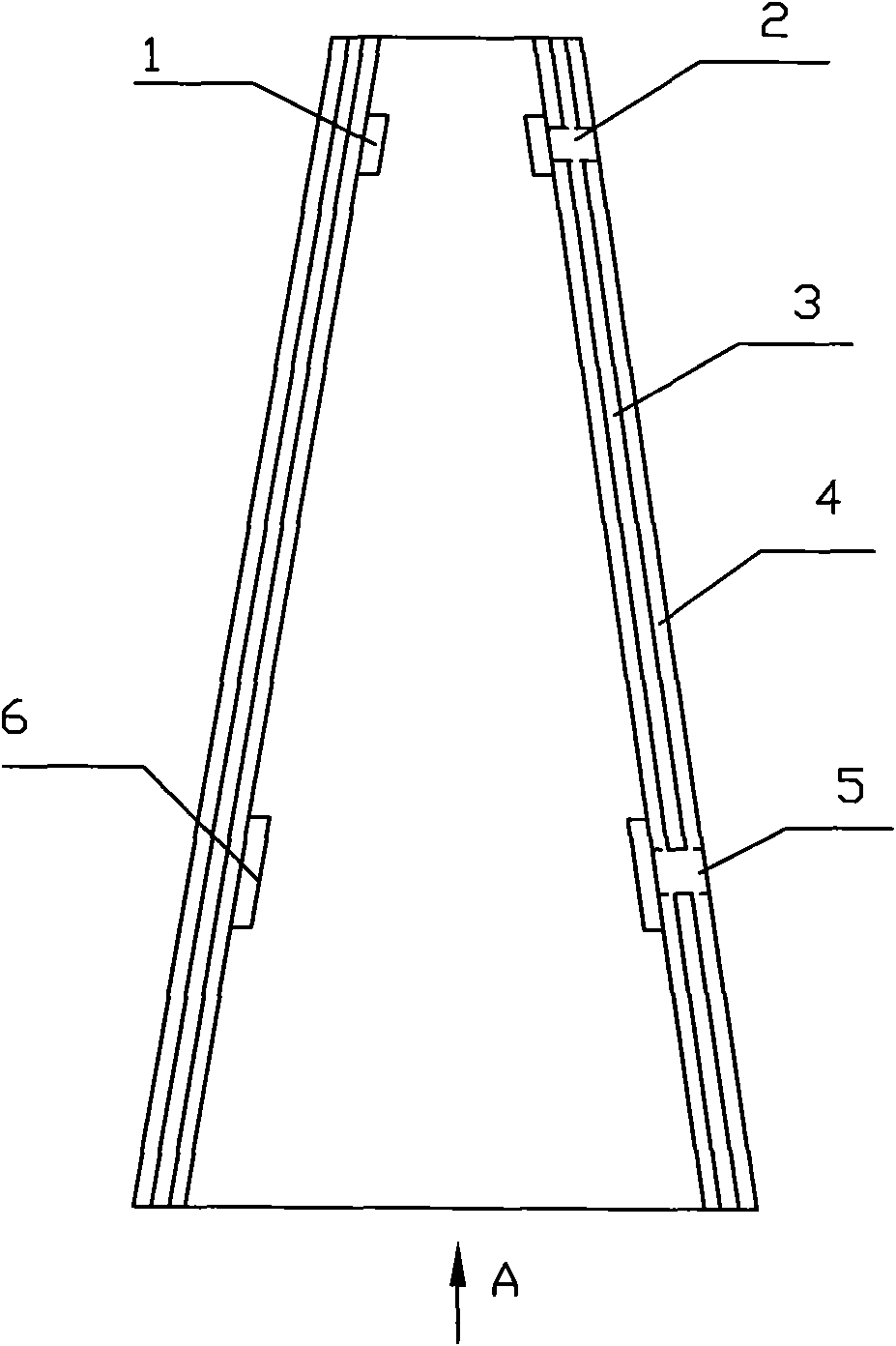

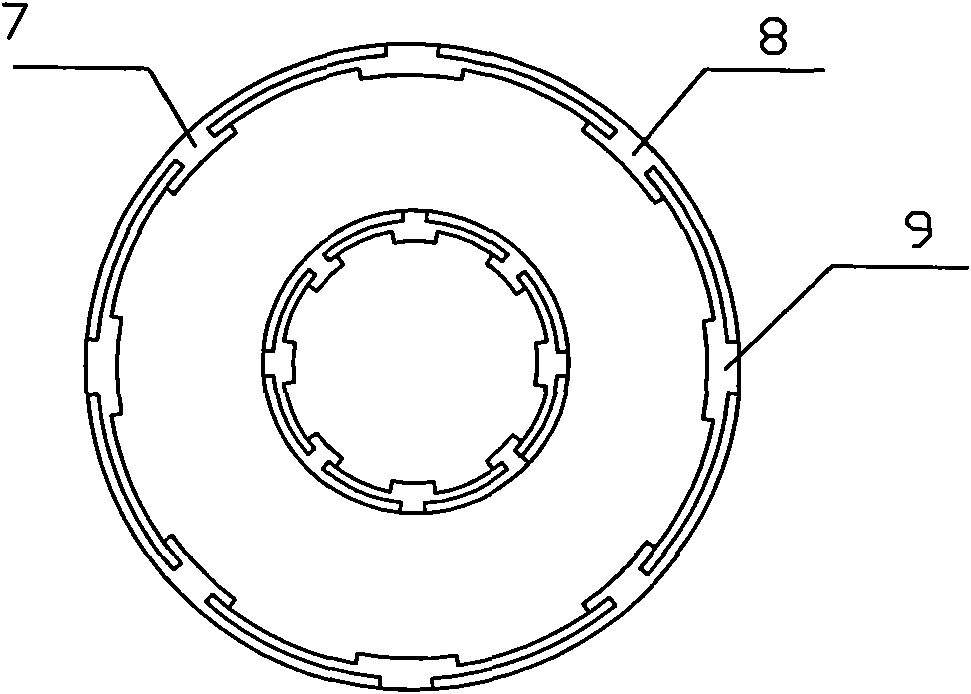

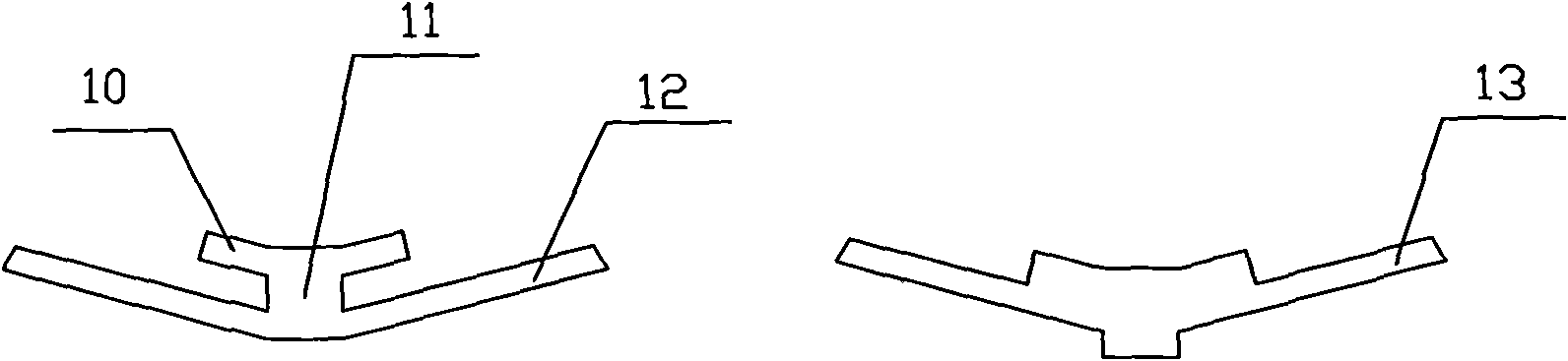

[0040] see figure 1 , 2 , in a preferred embodiment of the present invention, the tapered pole is assembled by eight trapezoidal slats 7 in a single buckle mode, wherein each of the mother board 8 and the daughter board 9 has 4, the surface of the tapered pole of the present invention The resin-rich fiber tape is radially wound to form a fastening layer, which can enhance the anti-ultraviolet ability, and fasten the tapered utility poles formed by assembling to ensure the proper design strength. The outer surface of the tapered pole is impregnated with an anti-ultraviolet coating 3 to improve the ability to resist atmospheric erosion. The upper end and the lower end of the tapered electric pole all leave the grounding wire inlet and outlet holes 2,5, the upper end grounding wire inlet and outlet hole 2 prevents rainwater from entering, and the lower end grounding wire inlet and outlet hole 5 can drain accumulated water to prevent the pole from ice swelling and rupture. Both ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap