Integral multi-way reversing valve

A multi-way reversing valve, integrated technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of large leakage between plates, easy contamination of oil, large pressure loss, etc. , to achieve the effect of high pressure resistance, good compactness and loss control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

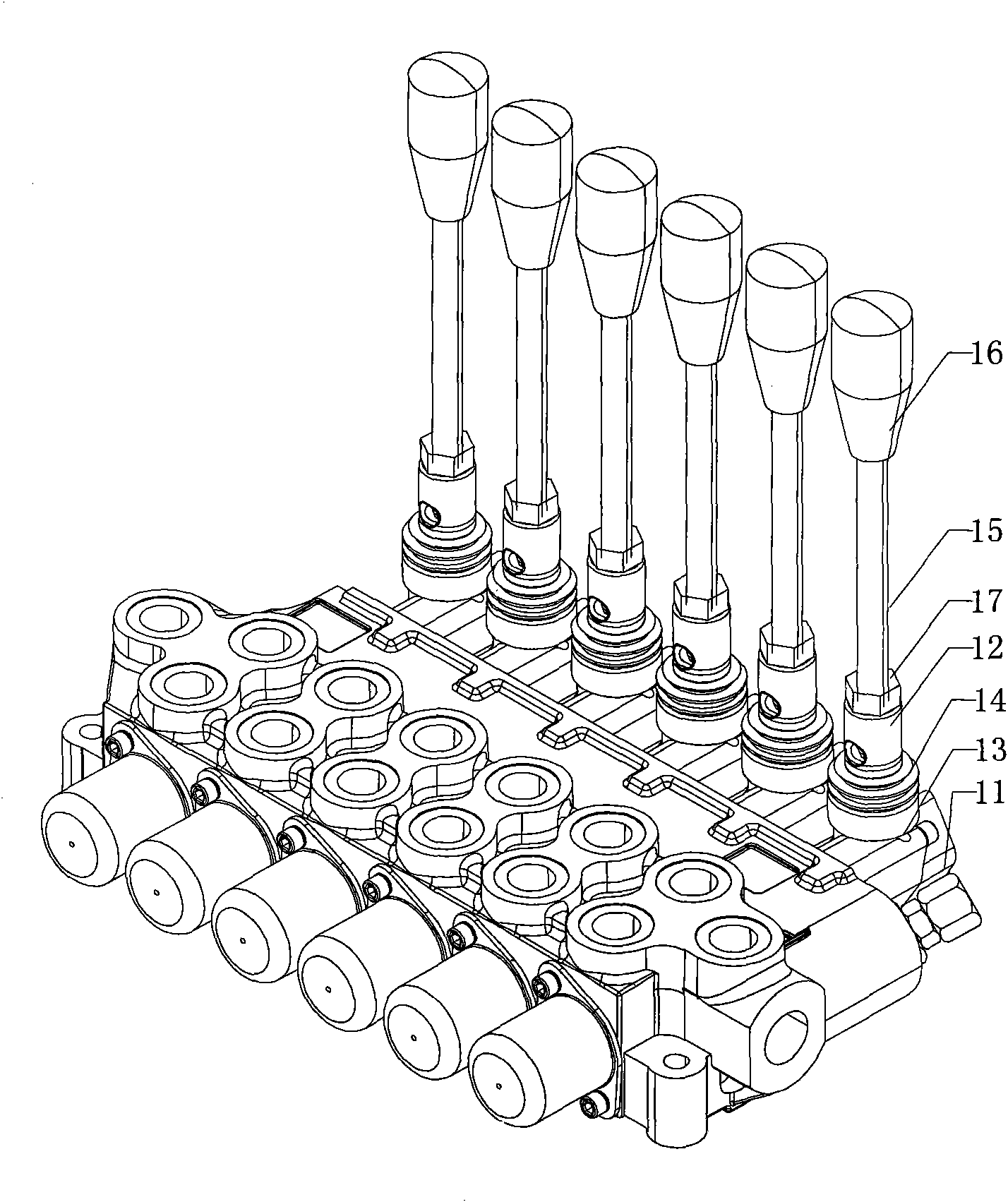

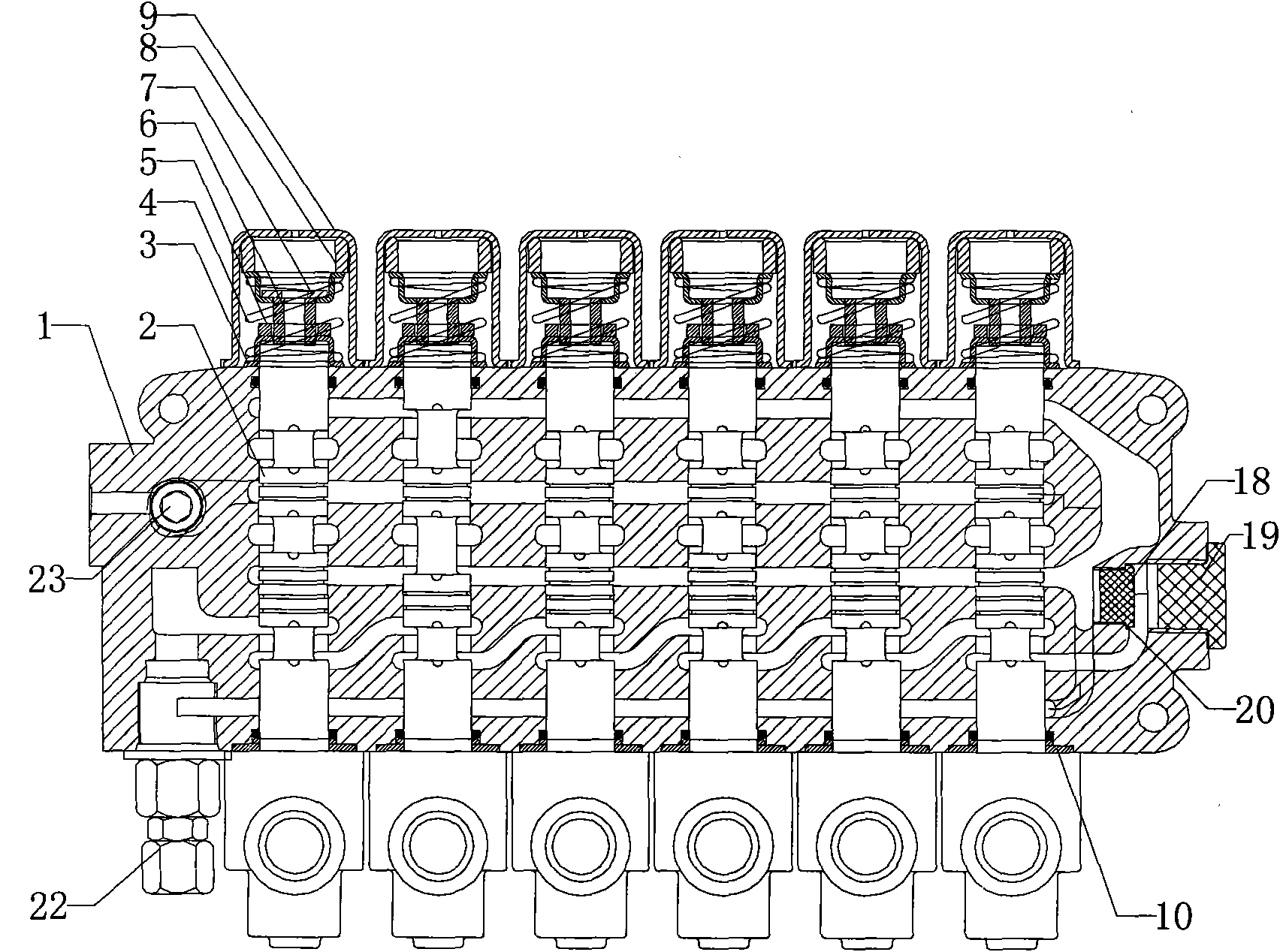

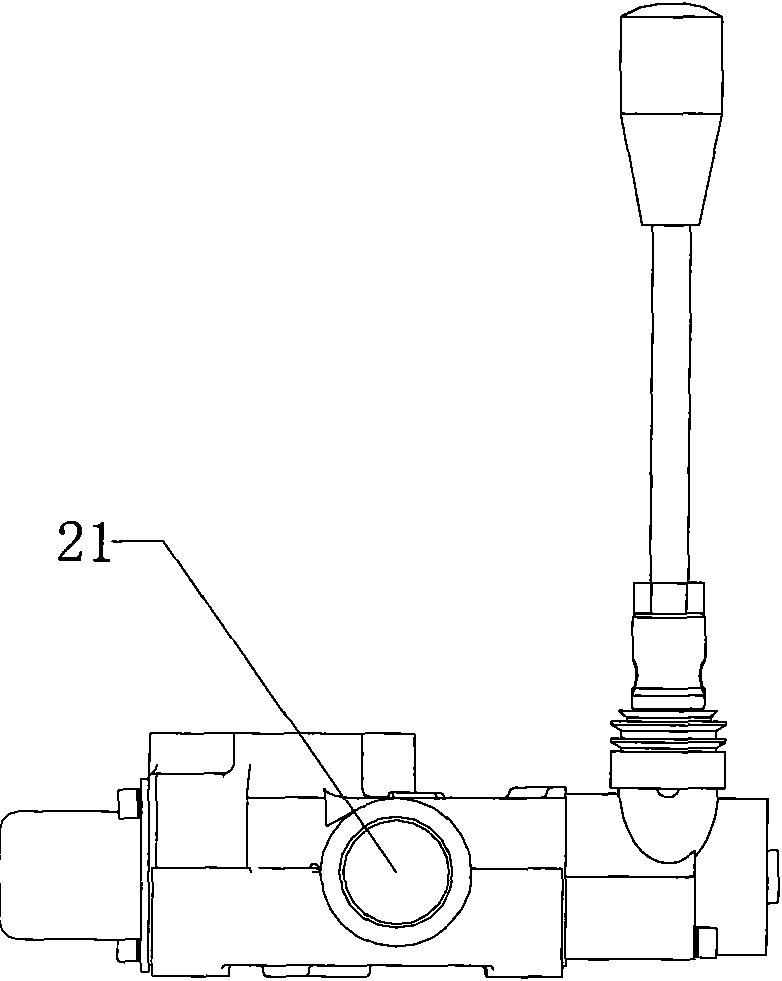

[0015] Such as Figure 1-4 As shown, the integral multi-way reversing valve described in the embodiment of the present invention includes a control handle, a valve body 1, an end cover 9 and a front cover 8, and the control handle is composed of a handle 16, a control lever 15, a pin shaft 12 The upper end of the joystick 15 is connected to the handle 16, and the lower end is connected to the pin shaft 12 through threads. The upper part of the pin shaft 12 is provided with a fastening nut 17, and the lower part of the pin shaft 12 is connected to the end cover 9 through a pin 13. The inside of the valve body 1 is provided with a valve stem 2, the outside of the valve body 1 is provided with a plug hole 21, the inside of the plug hole 21 is provided with an M16x1 plug 18, and an O-ring 20 is provided at its connection, The outside of the plug hole 21 is sealed by a G3 / 8 plug 19; the two ends of the valve body 1 are respectively threaded with the end cover 9 and the front cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com