Double-sided variable speed flange

A variable-speed flange and double-sided technology, which is applied to flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems that are difficult to solve on-site connection problems, and there are no double-sided variable-speed flanges used and reported. , to achieve the effect of simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

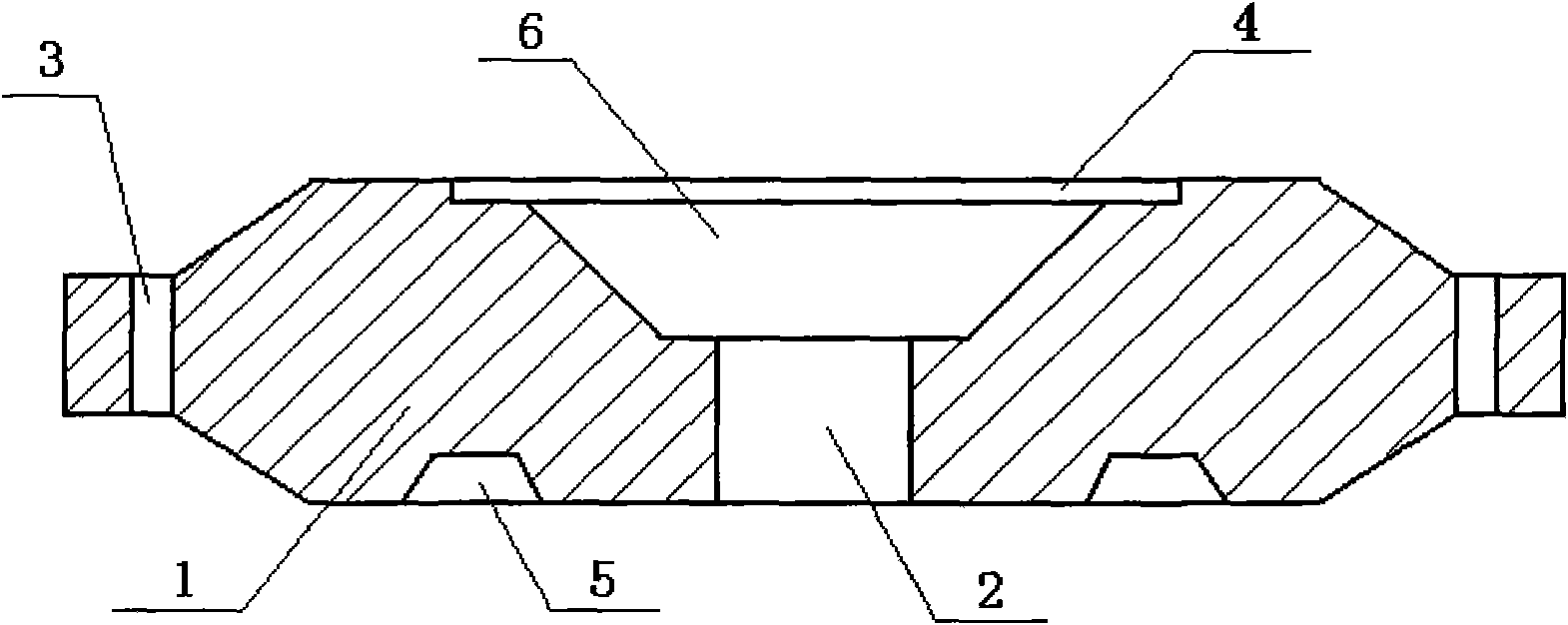

[0016] Embodiment one: according to figure 1 It can be seen that the double-sided speed-changing flange of the present invention includes a flange body 1, a through hole 2 at the center of the flange body, and a bolt hole 3 at the edge of the flange body, and one end surface of the flange body 1 is annular. The concave-convex sealing surface 4, the other end surface is an annular groove sealing surface 5, the longitudinal section shape of the annular groove sealing surface is trapezoidal, and the center position of the flange body 1 corresponding to the annular concave-convex sealing surface 4 is set There is a transition hole 6 , the longitudinal section of the transition hole 6 is trapezoidal, and the minimum inner diameter of the transition hole 6 is larger than the inner diameter of the through hole 2 .

Embodiment 2

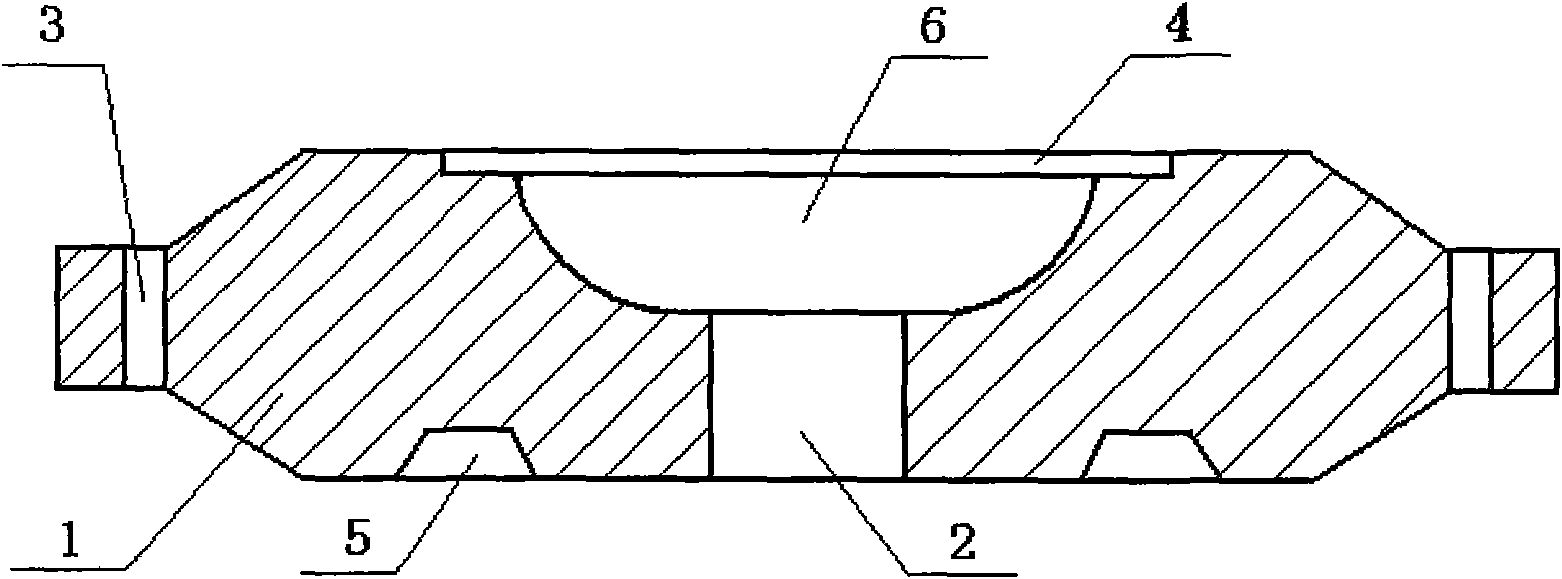

[0017] Embodiment two: according to figure 2 It can be seen that the double-sided speed-changing flange of the present invention includes a flange body 1, a through hole 2 at the center of the flange body, and a bolt hole 3 at the edge of the flange body, and one end surface of the flange body 1 is annular. The concave-convex sealing surface 4, the other end surface is an annular groove sealing surface 5, the longitudinal section shape of the annular groove sealing surface is trapezoidal, and the center position of the flange body 1 corresponding to the annular concave-convex sealing surface 4 is set There is a transition hole 6 , the longitudinal section of the transition hole 6 is bowl-shaped, and the minimum inner diameter of the transition hole 6 is larger than the inner diameter of the through hole 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com