Heavy-duty feed trolley device of large horizontal thermal treatment furnace

A technology for feeding trolleys and heat treatment furnaces, which is applied to furnaces, conveyors, furnace components, etc., can solve the problems of cantilevered trolleys that cannot meet the requirements of cantilever rigidity, unreliable working performance, and poor adaptability to heavy loads, and achieves stable and reliable structure. , The effect of reliable work and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

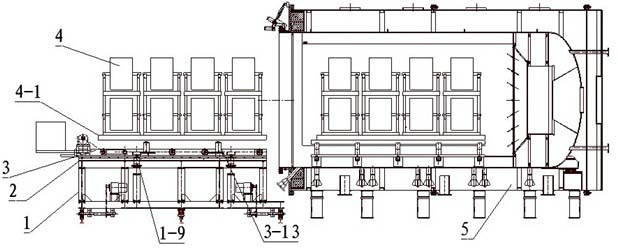

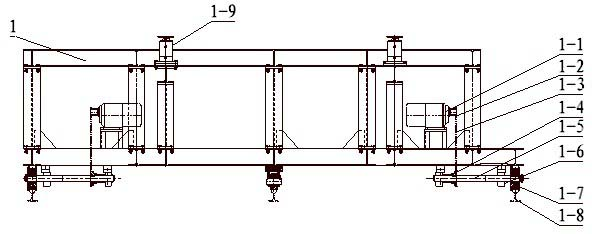

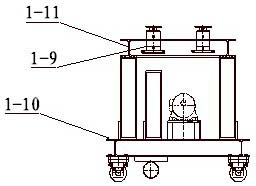

[0025] As shown in the figure, reference numerals explain: feeding trolley moving device 1, reducer 1-1, driving sprocket 1-2, sleeve roller chain 1-3, driven sprocket 1-4, drive shaft 1- 5. Outer spherical bearing with seat 1-6, roller mechanism 1-7, feeding trolley guide rail 1-8, lifting hydraulic cylinder group A 1-9, feeding trolley moving device bottom surface 1-10, feeding trolley moving device top surface 1- 11. Feeding mechanism guide rail propulsion device 2, including reducer 2-1, driving gear 2-2, driven rack 2-3, feeding mechanism guide rail 2-4, feeding mechanism guide rail support platform 2-5, feeding mechanism 3, Reducer 3-1, driving sprocket 3-2, sleeve roller chain 3-3, double driven sprocket 3-4, driven sprocket 3-5, drive shaft A 3-6, drive shaft B 3-7, deep groove ball bearing 3-8, driving roller mechanism 3-9, driven shaft 3-10, driven roller mechanism 3-11, feeding rack 3-12, lifting hydraulic cylinder group B 3-13, Material rack 4, material rack botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com