Peeling jig of dust-proof film assembly and peeling method

A technology for dust-proof film components and fixtures, applied in electrical components, components for opto-mechanical processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of high risk of photomasks and poor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Examples of the present invention will be described below, but the present invention is not limited thereto.

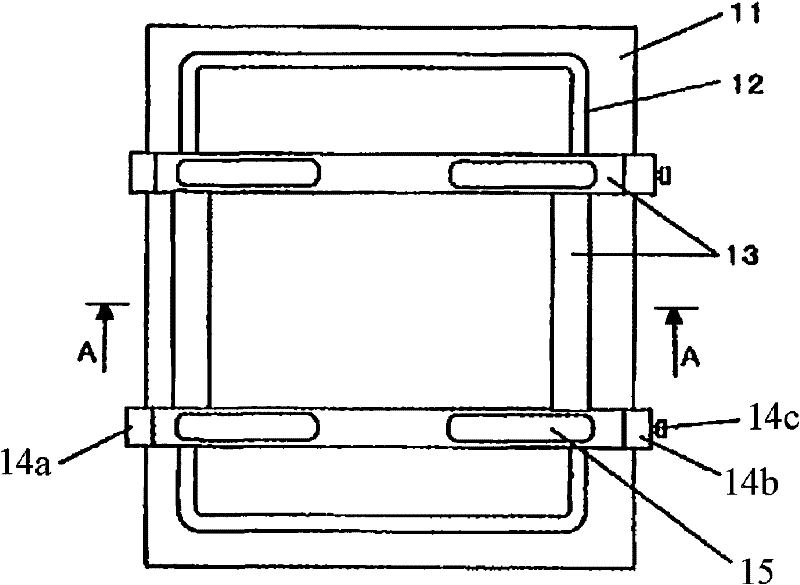

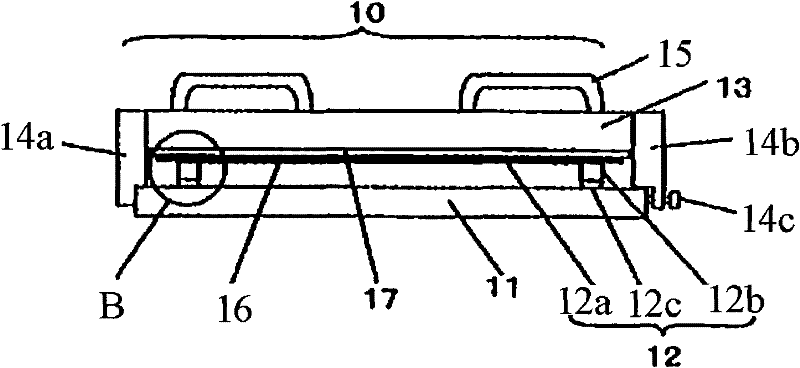

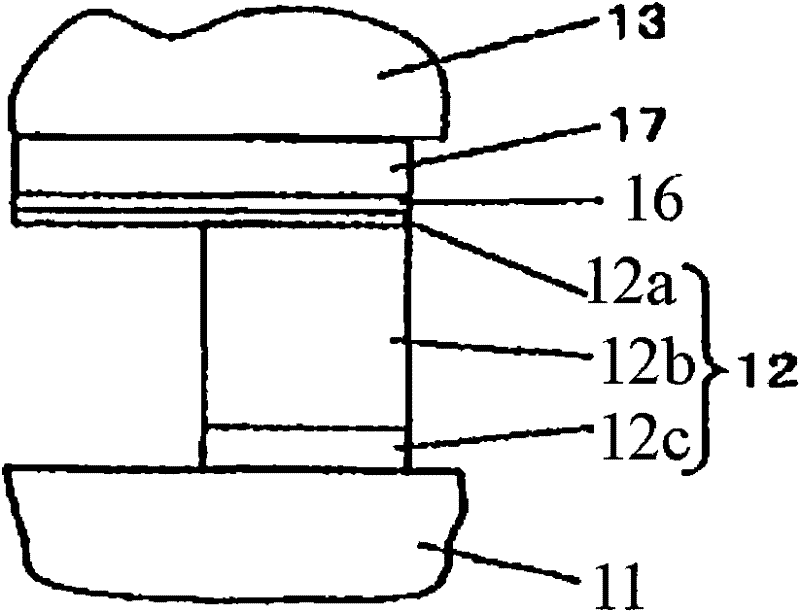

[0066] A pellicle peeling jig having the structure shown in Fig. 1 was produced. The base 13 is made into a frame shape with a pressed hollow material of A6063 aluminum alloy with a cross-section of 30mm×30mm, and the first arm 14a and the second arm 14b made of antistatic ultra-high molecular polyethylene are mounted on both ends . A screw member 14c made of antistatic MC nylon is attached to the second arm portion 14b. In addition, a handle 15 made of antistatic resin is attached to the base 13 .

[0067] Then, under the base 13, a base member 17 made of antistatic PVC is provided. Then, apply a silicone adhesive (trade name KR3700 / manufactured by Shin-Etsu Chemical Co., Ltd.) on both sides of a PET film with a thickness of 100 μm, and make the film thickness after drying to 50 μm. After heating and curing, it is cut into base members 17 shape, attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com