Torque Alignment Nut And Installation Tool

A nut and tool technology, applied in the field of fluid flow control equipment, can solve problems such as easy deformation or rounding of nuts and tools, large operator cost and investment, and reduced efficiency, so as to improve operator efficiency, reduce operating costs, and facilitate Removed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

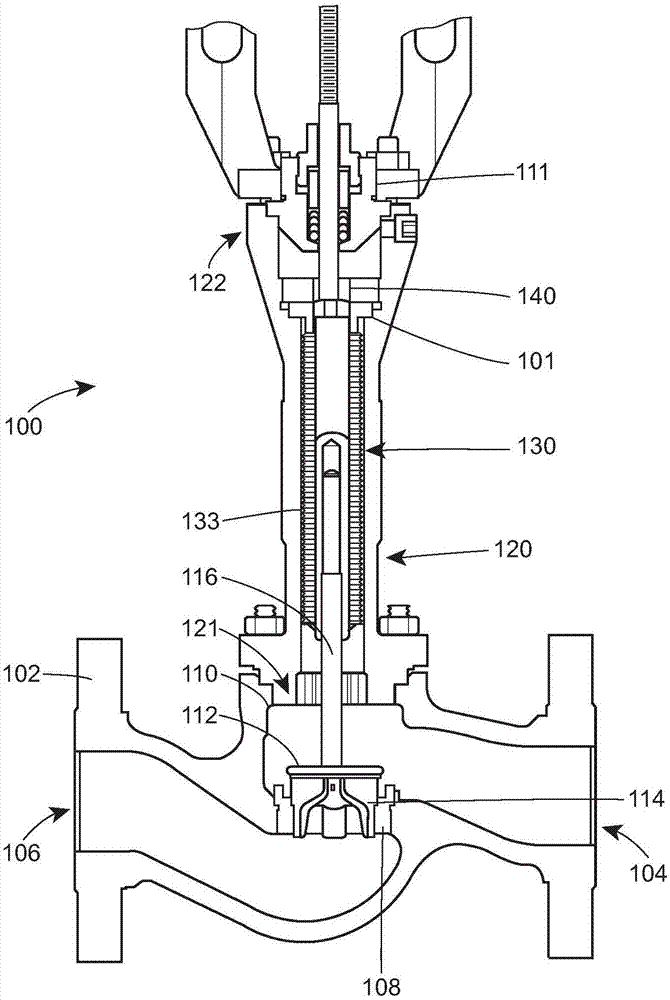

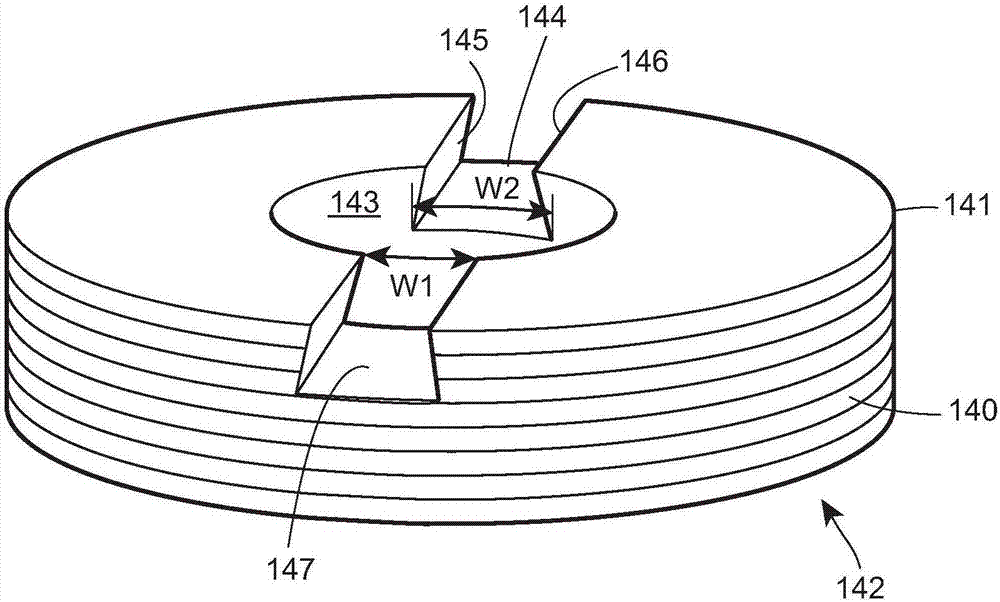

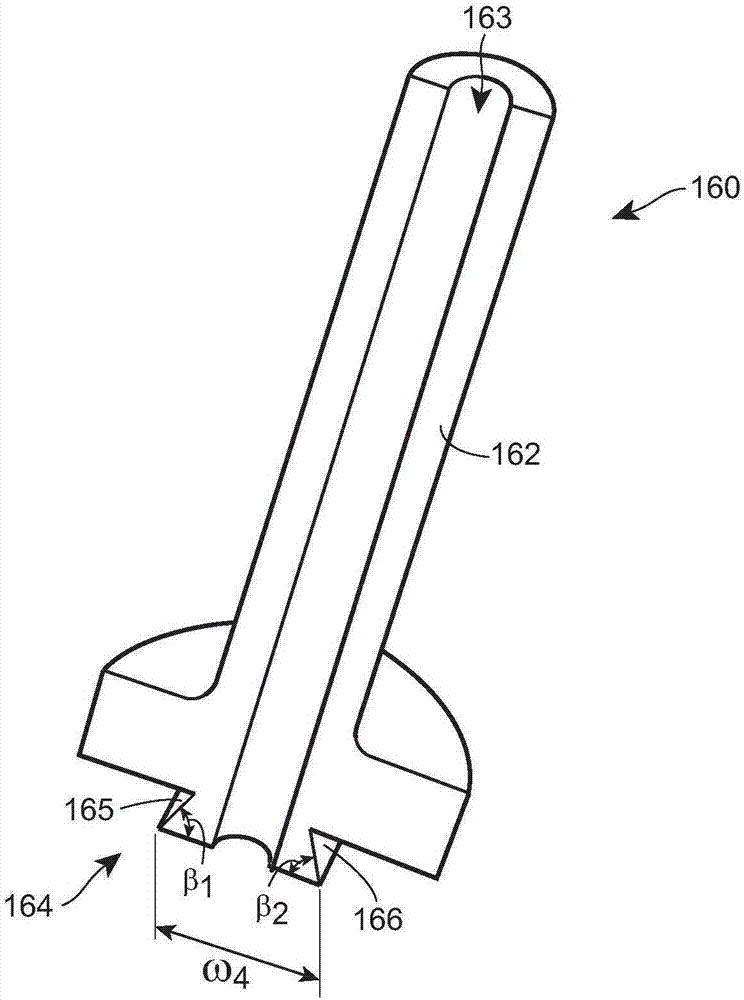

[0017] In general, the present disclosure relates to fluid flow control devices 100 (eg, valves or regulators) for regulating fluid flow. like figure 1 As shown, apparatus 100 includes a valve body 102 defining an inlet 104 , an outlet 106 , a throat 108 disposed between inlet 104 and outlet 106 , and a bonnet opening 110 . Apparatus 100 also includes a control element 112 disposed within throat 108 of valve body 102 , and apparatus 100 includes a valve plug 114 and an elongated stem 116 coupled to valve plug 114 . The apparatus 100 also includes an extension bonnet 120 , a bellows 130 disposed in the extension bonnet 120 , and a bellows nut 140 . System 100 may include any number of additional components and / or subsystems (such as, for example, including a valve coupled to valve body 102 at throat 108 ) as known to those skilled in the art and will not be described herein for the sake of brevity. seat trim assembly, any number of gaskets, bushings, etc.). An example of dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com