Electric motors for actuating drives or wiper drives of motor vehicles

A technology for electric motors and motor vehicles, which is applied to the cleaning of electromechanical devices, electric components, vehicles, etc., can solve the problems of reducing the efficiency of the worm drive mechanism, the wear of the free end of the armature shaft, and reducing the diameter of the worm tooth root circle. Easy to make, compensate for shape error, good effect of meshing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

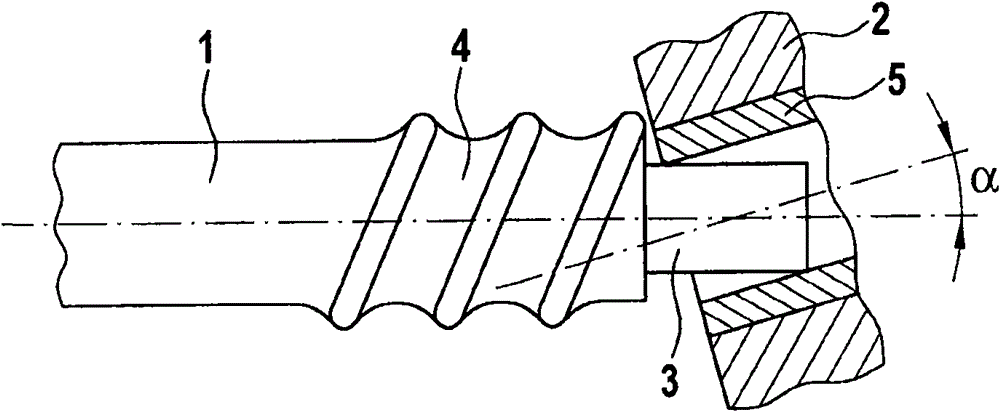

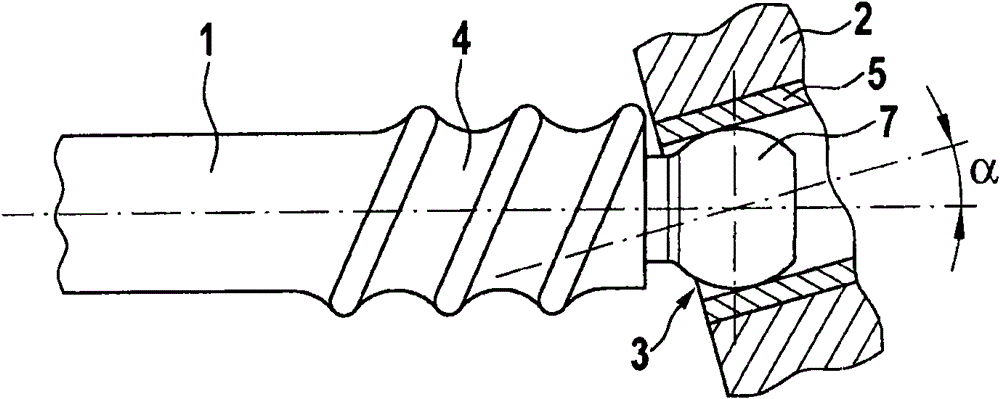

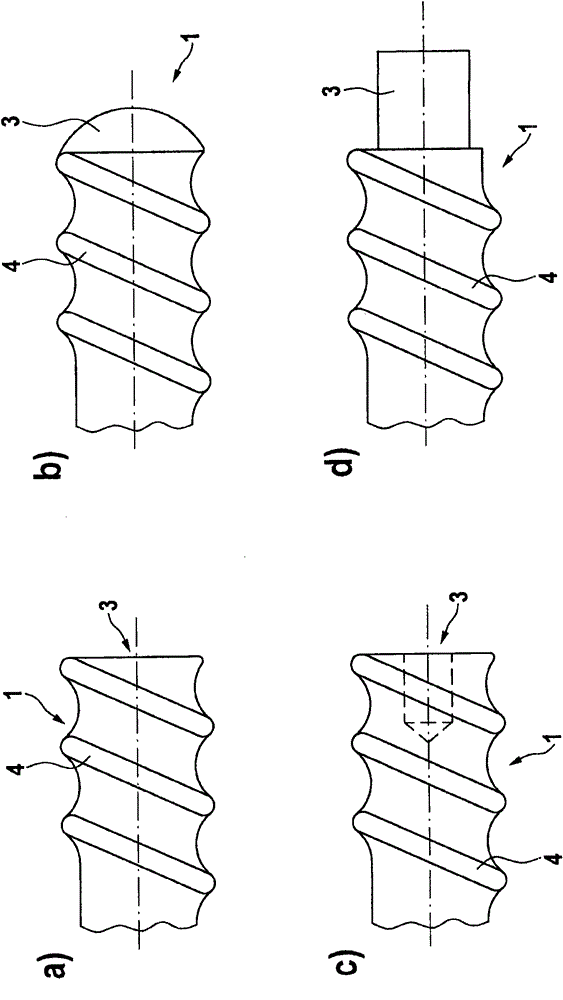

[0020] figure 1 Shown is an electric motor for an adjustment drive or wiper drive of a motor vehicle, which has an armature shaft 1 , one end of which is rotatably mounted in a transmission housing 2 , and its other free end 3 There is a worm 4 for driving a worm or helical gear (likewise not shown) arranged in the gear housing 2 . In order to achieve support in the case of large deflections (which in particular lead to a coaxial deviation between the transmission housing 2 and the armature shaft 1 ), the free end 3 of the armature shaft 1 is arranged in a housing formed in the transmission housing 2 . Body 5 and supported therein. Here, the free end 3 of the armature shaft 1 is formed cylindrically. In this exemplary embodiment, the receiving body 5 is also designed cylindrically, which has the result that the free end 3 becomes stuck in the receiving body 5 when the axes of the armature shaft 1 and the receiving body 5 are strongly inclined relative to one another. So-cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com