Torque limiter

A torque limiter and shear valve technology, applied in the direction of couplings, slip couplings, rigid shaft couplings, etc., can solve problems such as difficult torque limiter re-running, to achieve fast scattering, easy Scattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, the present invention will be described in detail based on the embodiments in the drawings.

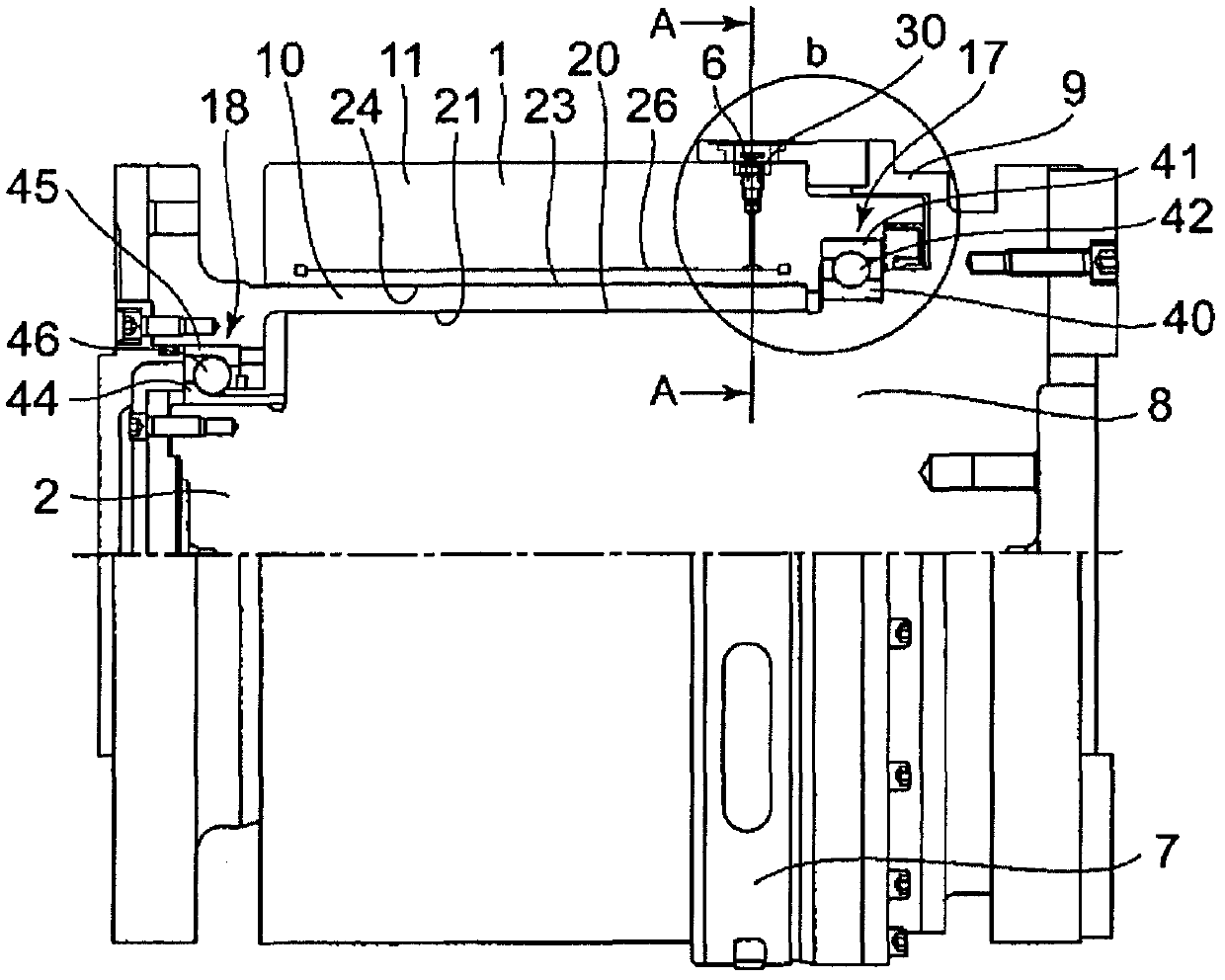

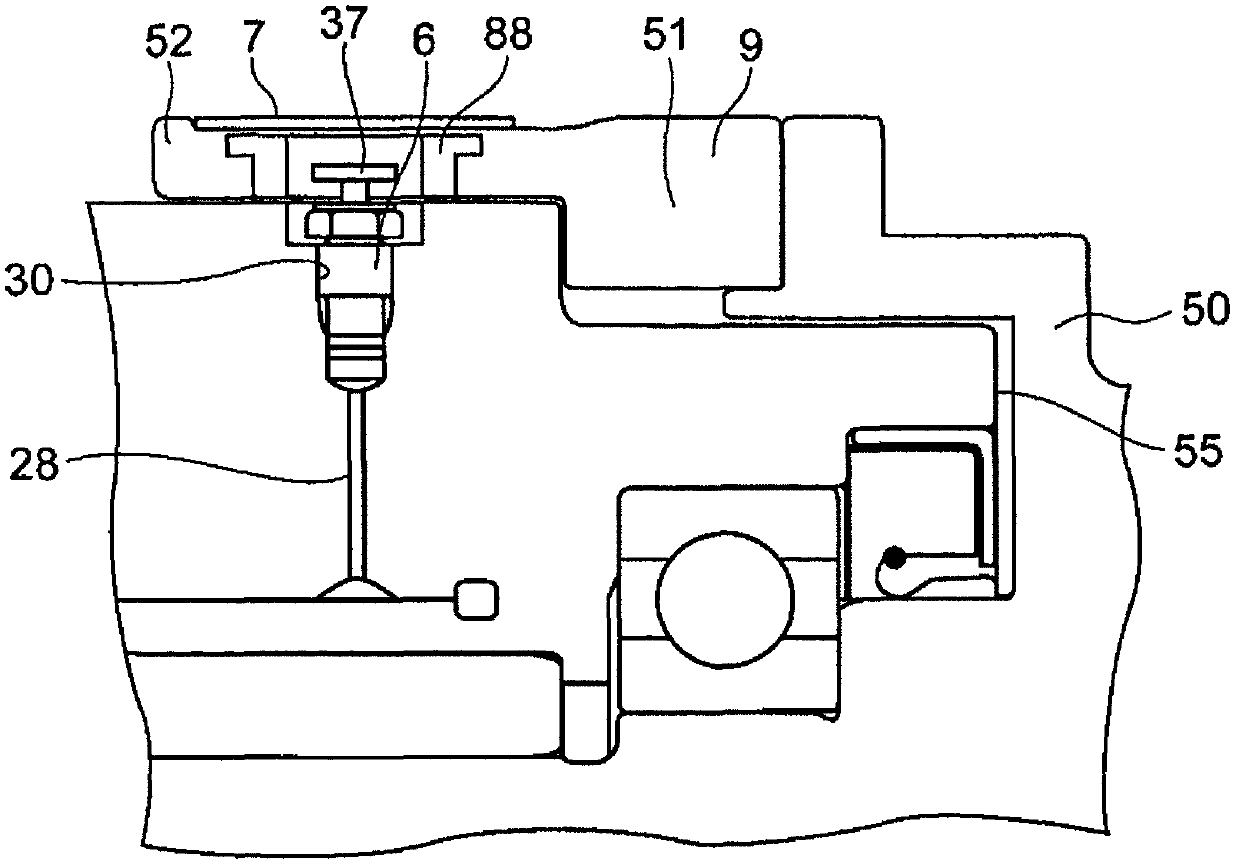

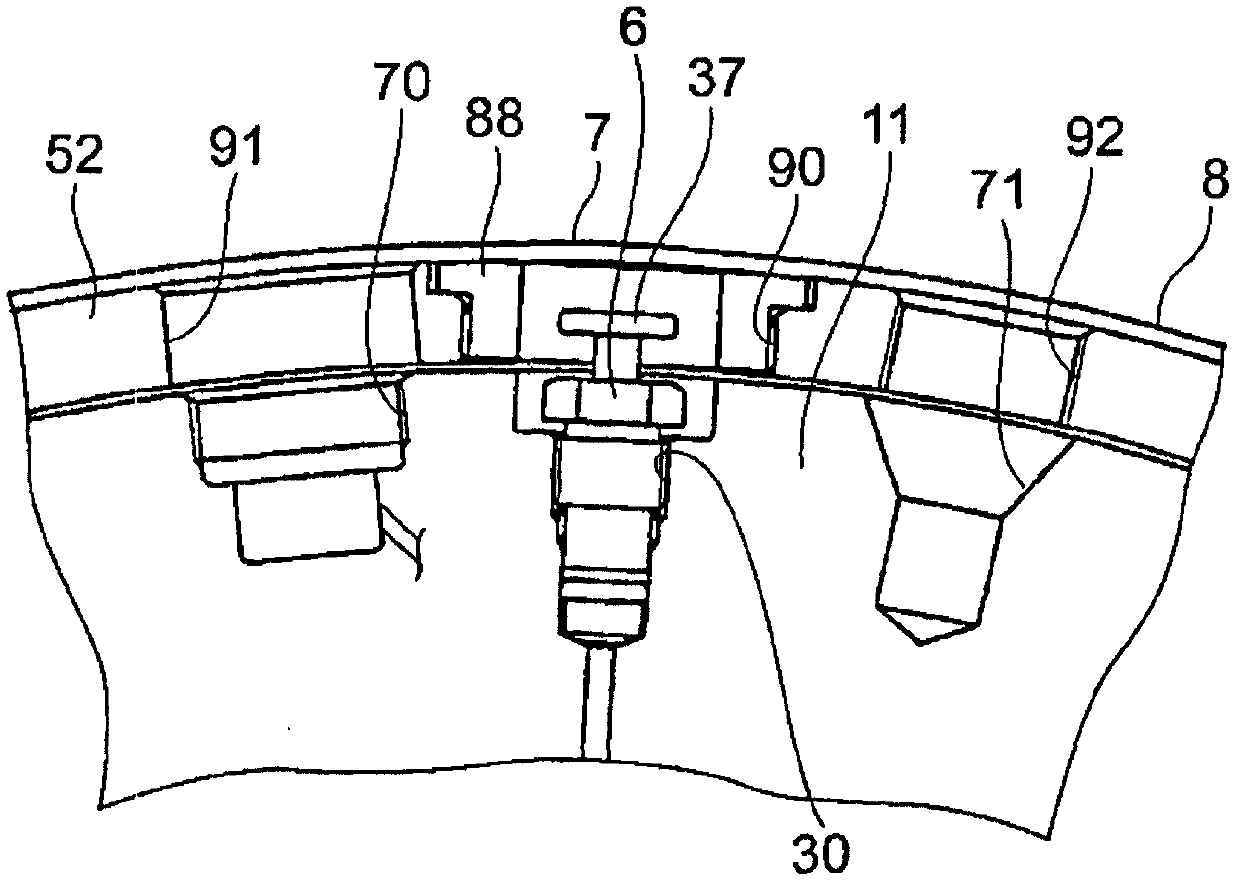

[0051] figure 1 It is an axial schematic diagram of the torque limiter of the first embodiment of the present invention. in figure 1 Among them, the upper half shows an axial cross section of the torque limiter, and the lower half shows a perspective view of the torque limiter.

[0052] The torque limiter includes a cylindrical member 1, a shaft member 2, four shear valves 6, a shear valve protection member 7, a ball bearing 17, and a ball bearing 18.

[0053] The cylindrical member 1 is composed of a first cylindrical member 10 and a second cylindrical member 11. The first cylindrical member 10 has a substantially cylindrical inner peripheral surface 21 that abuts the outer peripheral surface 20 of the shaft member 2. There is an anti-seize lubricant (traction oil or turbine oil) between the outer peripheral surface 20 of the shaft member 2 and the inner peripheral sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com