HBAR resonator stable at high temperatures

A resonator, temperature coefficient technology, applied in electrical components, impedance networks, etc., can solve problems such as poor temperature stability, frequency thermal drift, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

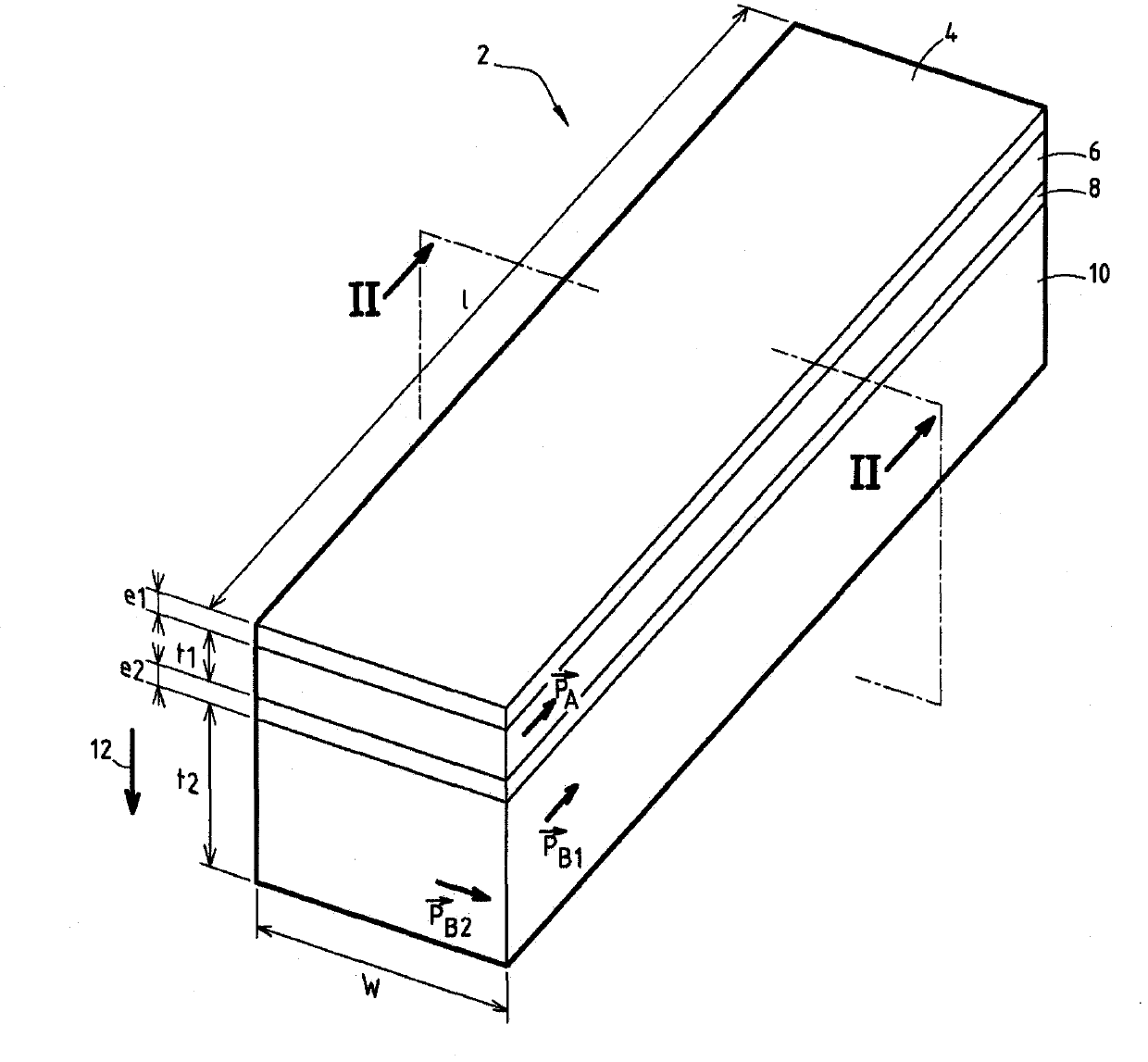

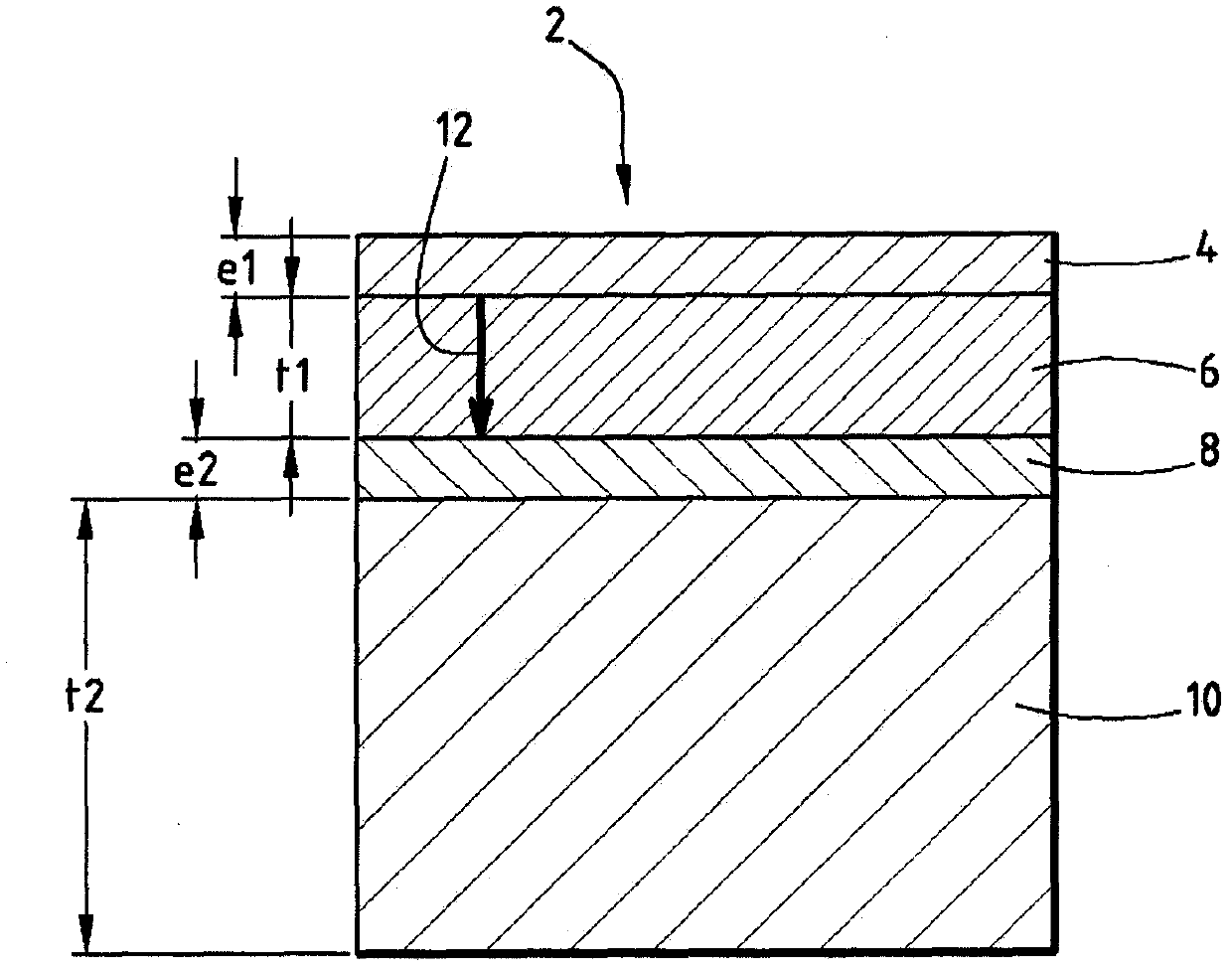

[0069] figure 1 with figure 2 An embodiment of the high-body acoustic resonator 2 according to the present invention is shown.

[0070] The resonator 2 includes a stack of continuous layers, which includes:

[0071] The thickness made of aluminum is e 1 The upper electrode 4;

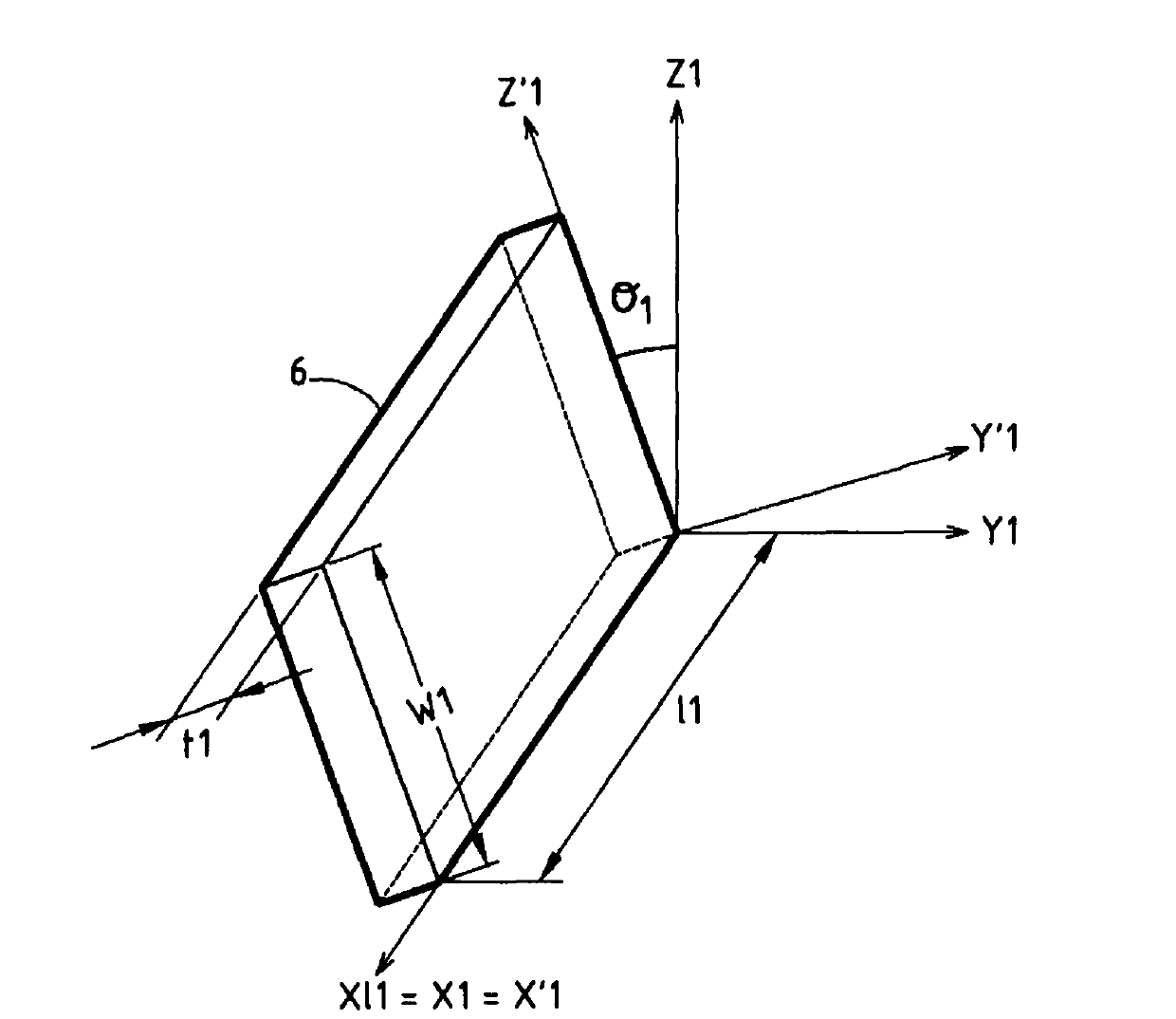

[0072] Composed of the first material with a first thickness t 1 The piezoelectric transducer 6, the first material is single crystal lithium niobate (LiNbO3);

[0073] The thickness made of gold is e 2 The embedded counter electrode 8;

[0074] Composed of a second material with a second thickness t 2 The acoustic substrate 10, where the second material is single crystal quartz.

[0075] figure 1 The layers 4, 6, 8 and 10 in the all have the same length l and width W, the length l is obviously greater than the width W and different layer thickness e 1 , T 1 , E 2 , And t 2 Big.

[0076] To simplify figure 1 , The electrodes 4, 8 are shown as sharing surfaces with the piezoelectric transducer 6.

[0077] Specifical...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap