Screen cloth structure of extrusion template of extruder

A technology for extruding template and extruder, applied in application, food preparation, food science, etc., can solve problems such as unevenness, and achieve the effects of increasing uniformity and maturation, better economic benefits, and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

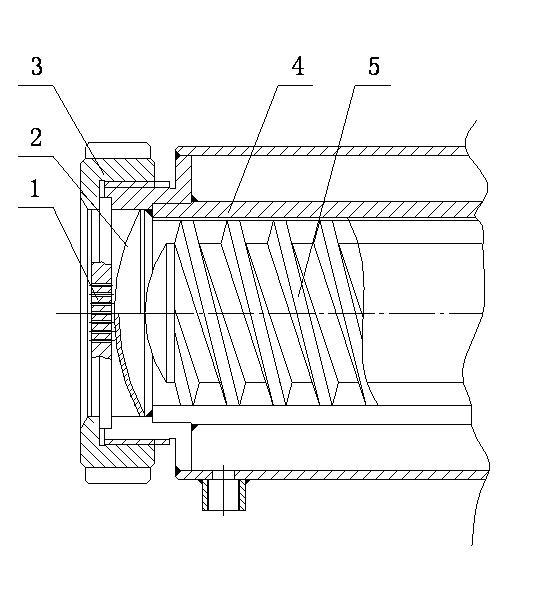

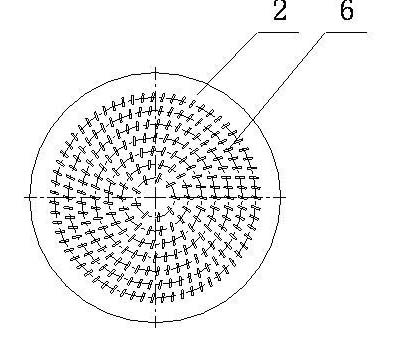

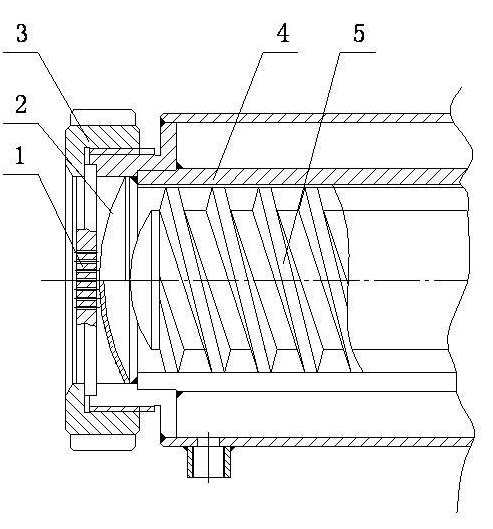

[0012] An extruder extrusion template screen structure, including a sleeve 4, a screw conveyor 5, an extrusion template 1, the screw conveyor is coaxially installed in the sleeve, and the extrusion template is installed on the sleeve through a fixing sleeve 3 discharge end. The innovation is that a screen 2 is installed between the extrusion template and the front end of the screw conveyor. The screen is a spherical screen. The screen is a spherical screen, and the mesh 6 made by the screen is a rectangular hole of 5x1mm.

[0013] The fabric of the fresh noodles is pushed by the screw conveyor, so that a certain pressure is formed in the sleeve, and the fresh noodles are extruded, and a screen is installed before the extrusion template and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com