Mandarin orange sac production line

A production line and cyst cell technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of difficulty in meeting hygiene standards, increasing the production cost of orange cyst cells, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

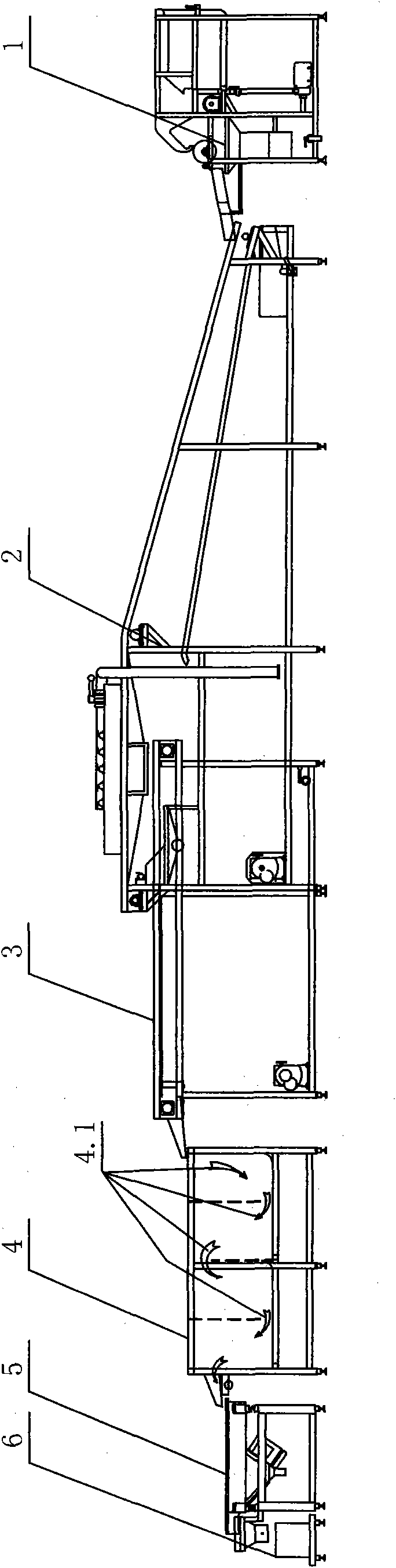

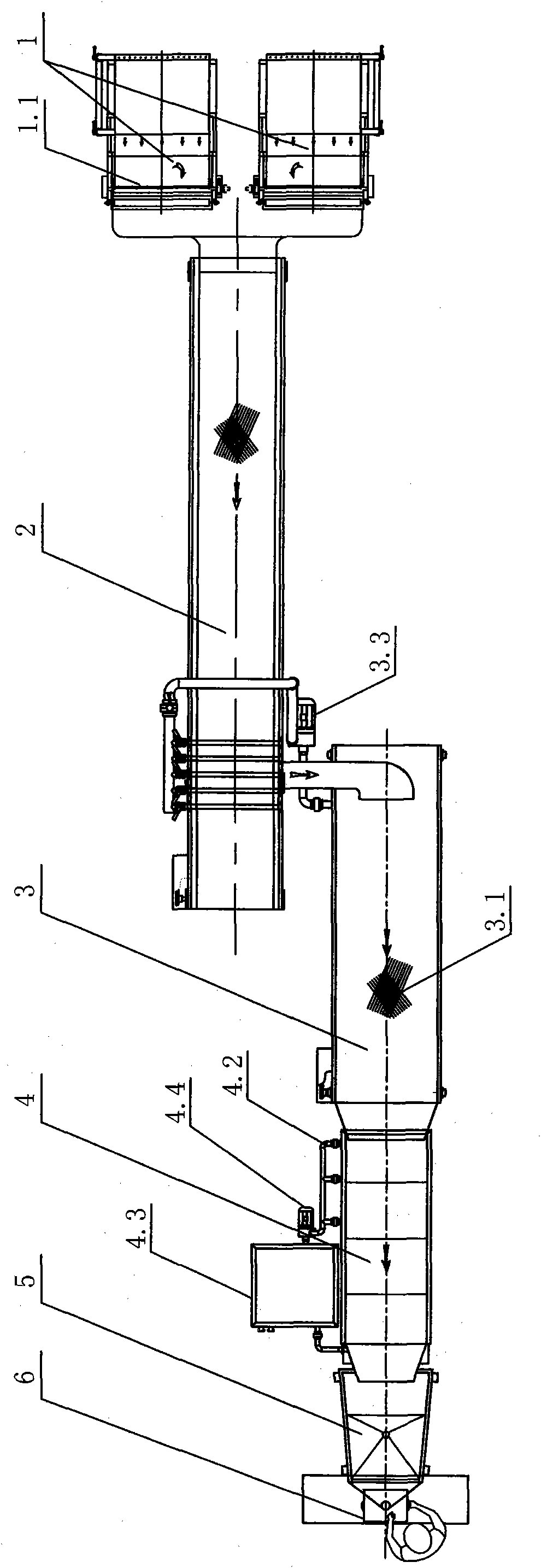

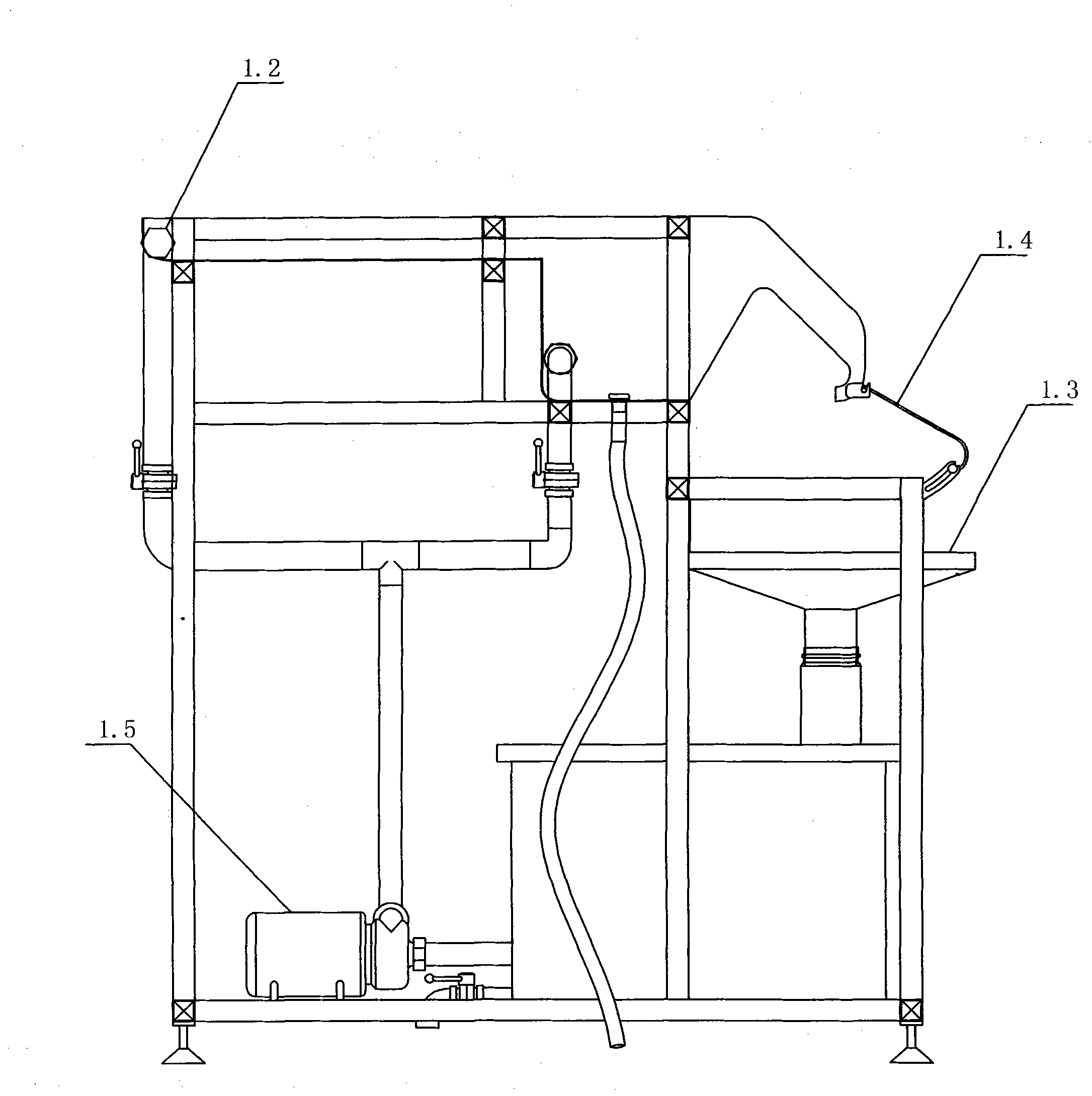

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Shown, a kind of orange vesicle production line of the present invention comprises the separating wave impurity removal machine 1 that is used for cleaning and dispersing orange slices that is arranged in sequence, the cyst breaker 2 that is used for breaking orange slices and forming cystic bodies, A mesh belt drainer 3 for cyst drainage, a cleaning separator 4 for removing impurities and separating cysts, and a drainage vibrator 5 for cyst drainage, the above-mentioned separating wave impurity removal machine 1 and cyst breaking machine 2 An orange slice conveying channel is provided between them, through which the orange slices can enter the cyst breaking machine 2 from the Segmentation Wave Impurity Removal Machine 1, and in this embodiment, the orange s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com