Interlocking type water guide disk set

A water-guiding plate and locking technology, applied in the field of interlocking water-guiding plate sets, can solve the problems of twisting deformation, gasket dislodgement, loss of watertight effect of water-guiding plate sets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

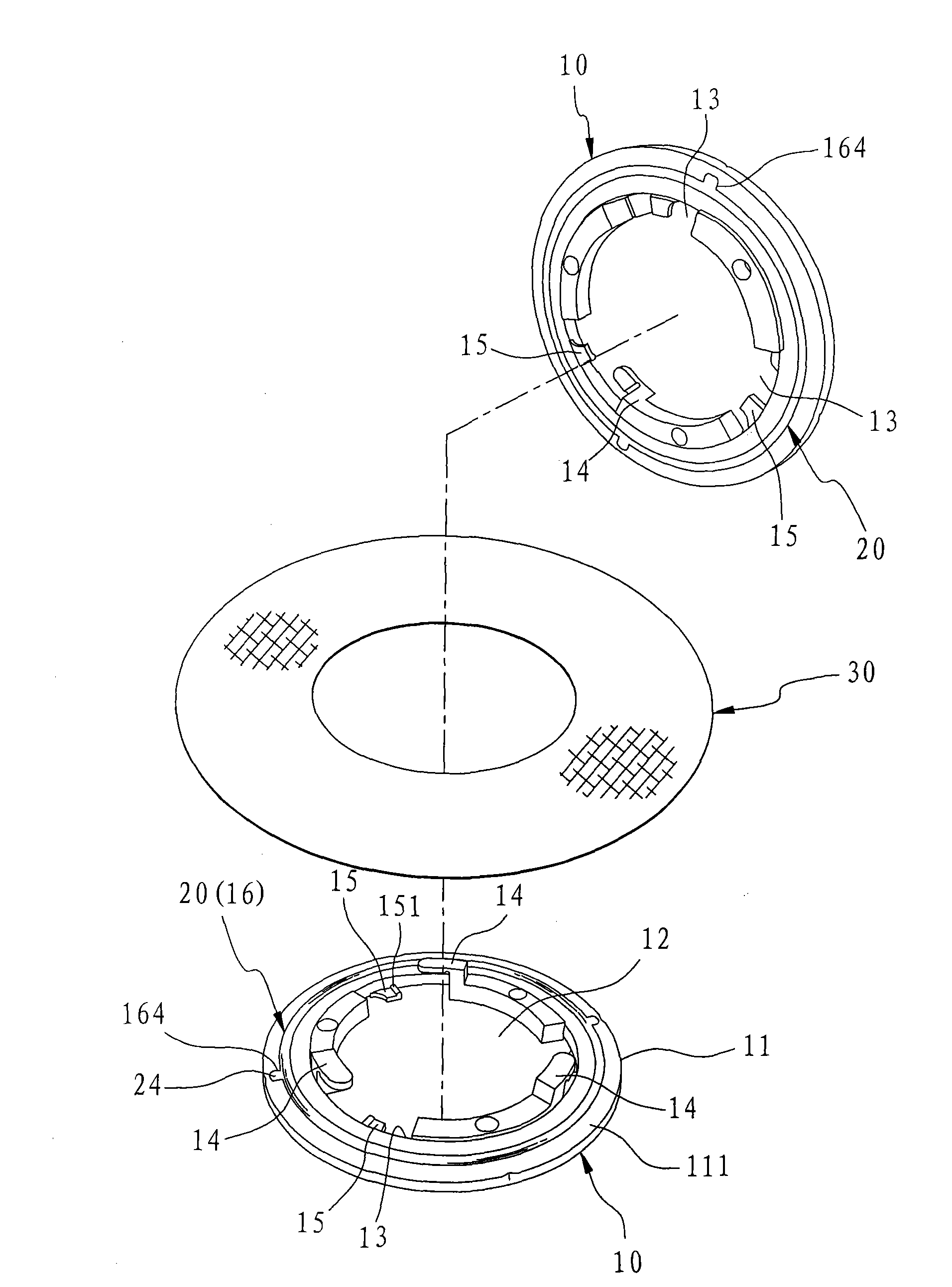

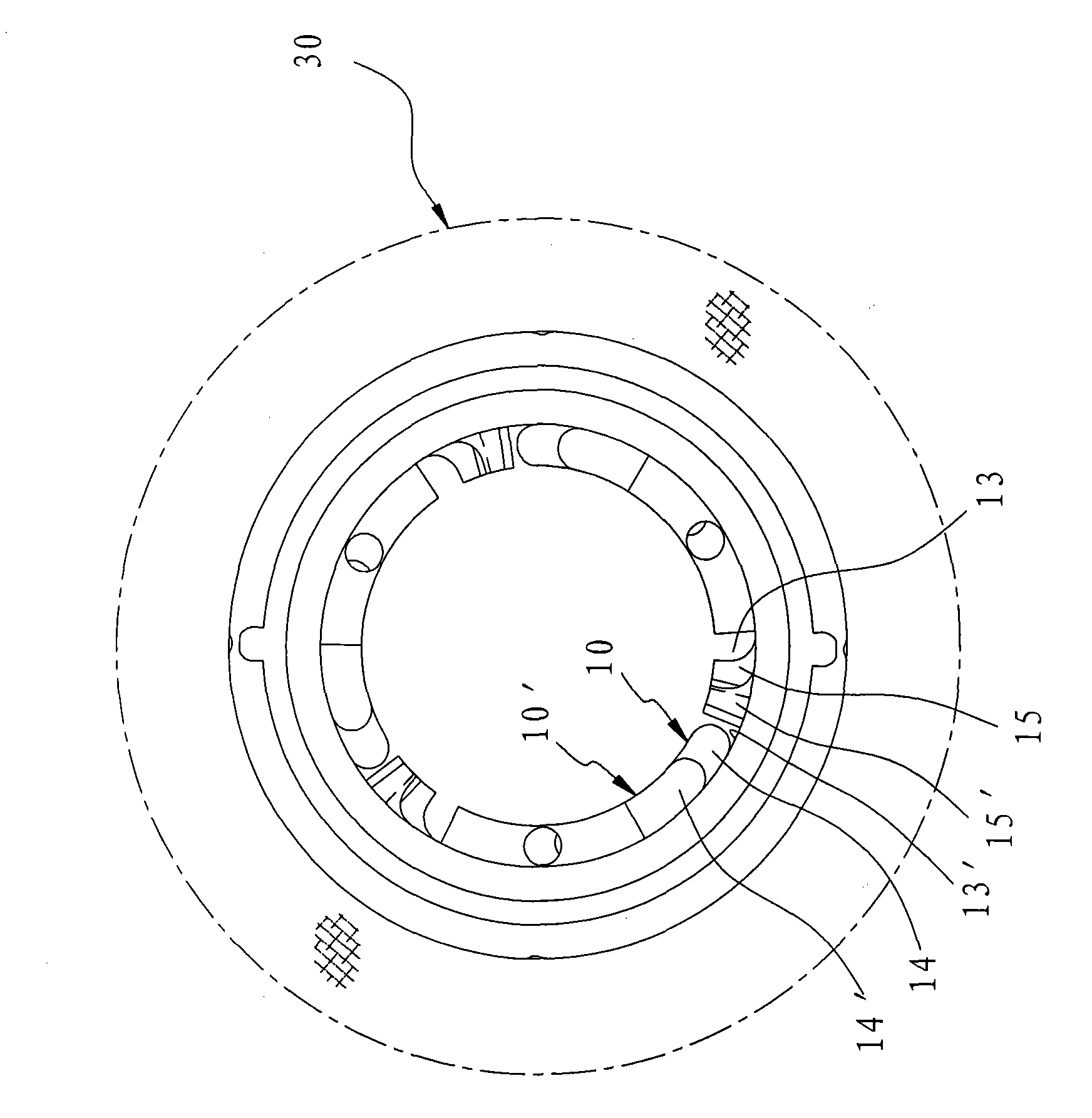

[0024] refer to figure 1 , The interlocking water guide pan set of the present invention includes a plurality of water guide pans 10 and a plurality of watertight components 20 .

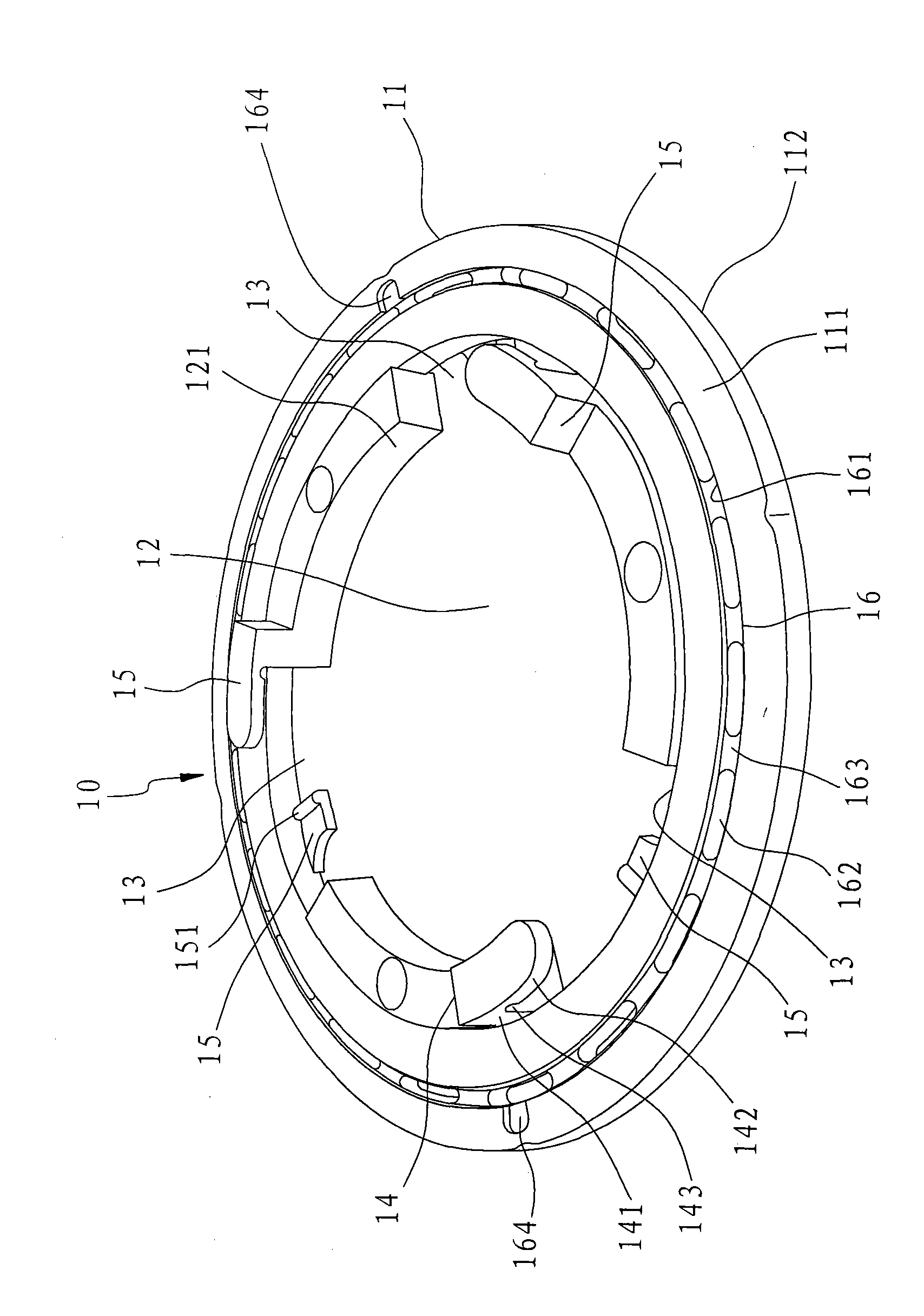

[0025] The aforementioned water guide plate 10, with reference to figure 2 , rotatably superimposed on each other, each water guide plate 10 has a disc-shaped body 11, a perforation 12 penetrating the body 11 along an axis X, and three annular wall surfaces 121 surrounding the axis X and from the perforation 12 The arc-shaped ring hole 13 opened on the top, three locking parts 14 extending outward from the disk surface 111 on one side of the body 11 and corresponding to one end of the ring hole 13, and three pairs of ring holes 13 extending from the disk surface 112 on the other side of the body 11 toward the ring hole 13. The joint part 15, and a positioning part 16 surrounding the ring hole 13 and recessed from the disk surfaces 111 and 112 on both sides of the body 11 respectively. In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com