Advanced secondary cooling water control system of billet continuous casting machine

A technology of secondary cooling water distribution and billet continuous casting, which is applied in the field of blast furnace automatic control and can solve the problems of the influence of secondary cooling water distribution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

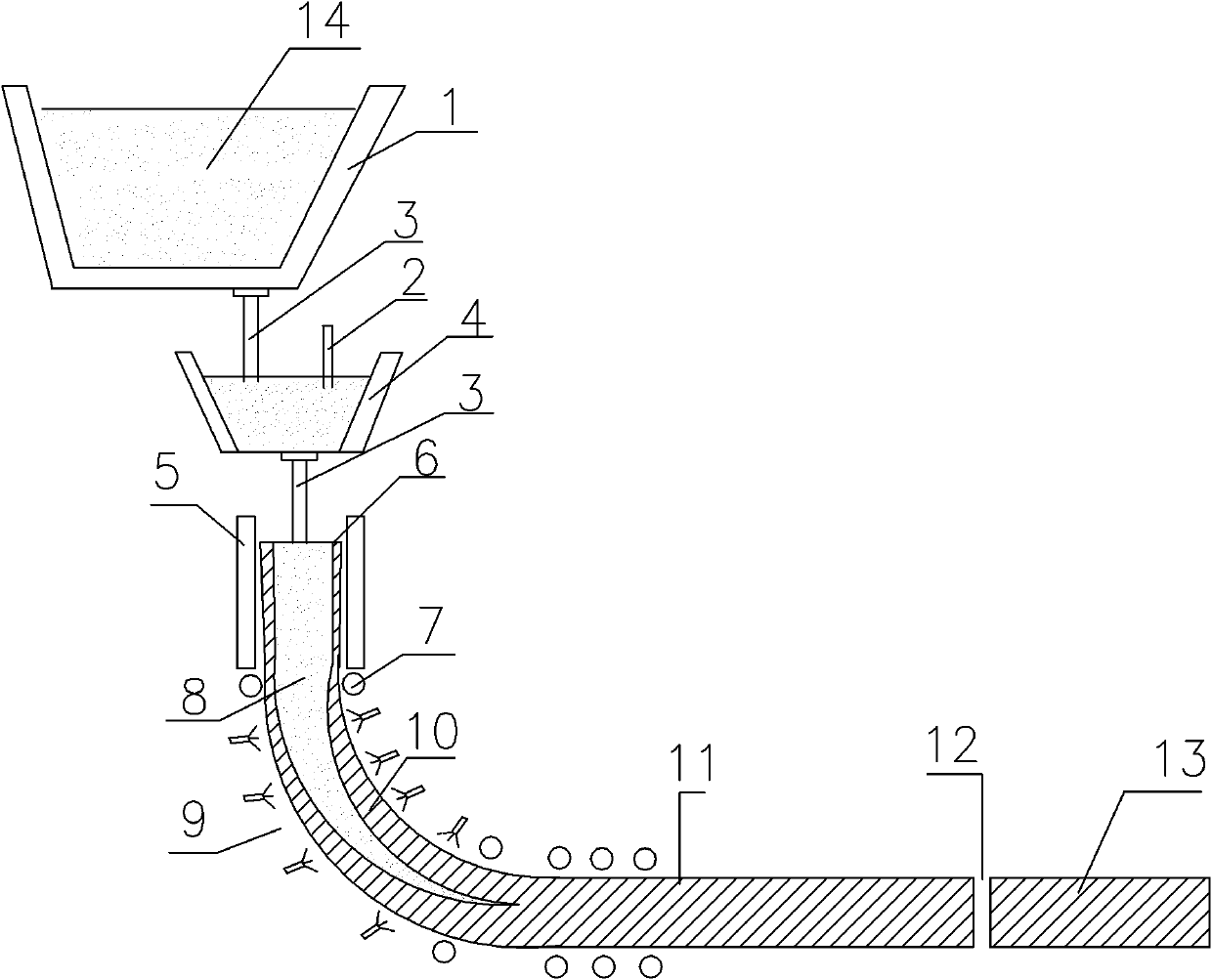

[0026] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

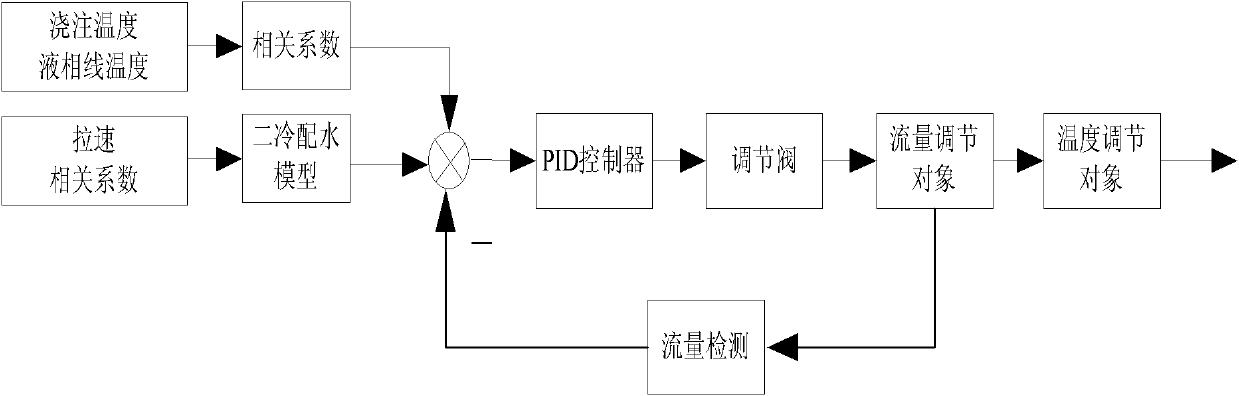

[0027] It is generally believed that the casting speed has a certain functional relationship with the secondary cooling water distribution. In actual operation, we found that due to the large fluctuation of the molten steel temperature on site, the large temperature drop of the tundish temperature during the pouring process, and the disturbance of the casting speed, etc. Therefore, it is difficult to obtain an accurate mathematical model for simultaneously considering the relationship between casting speed, tundish molten steel temperature and secondary cooling water distribution, and the control effect of traditional PID control method is not good.

[0028] In view of the above problems, we summarize the actual operation experience on site, and improve and control from the following two aspects:

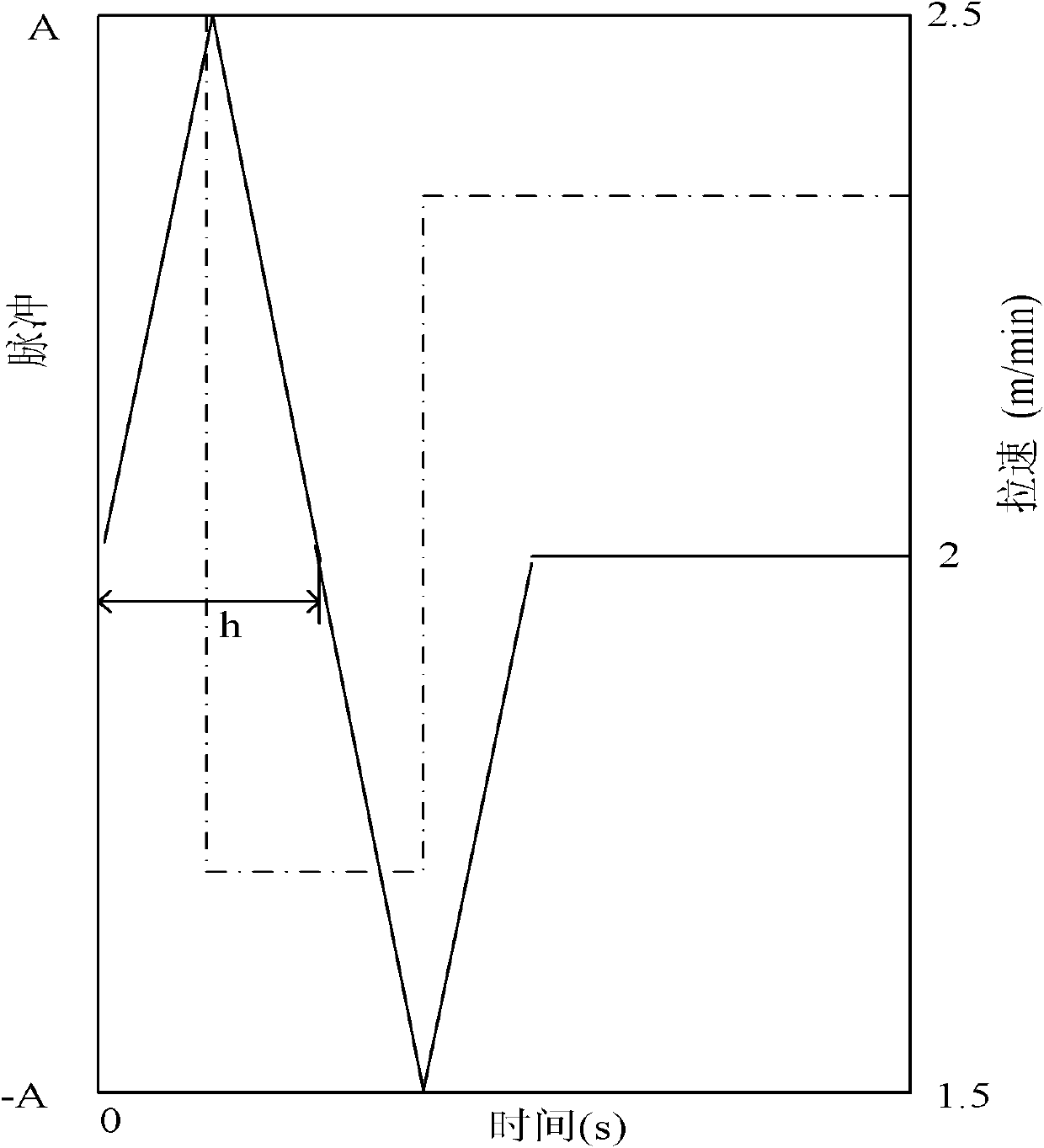

[0029] 1. In order to prevent the surface temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com