Coiling and pressing type metallic seal clamp

A technology of metal coils and clamps, which is applied in the field of postal seals, can solve the problems of bulky clamps, low work efficiency, and high labor intensity, so as to ensure the quality and safety of mail transportation, prevent errors in sealing and delivery specifications, and seal bags Strong and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

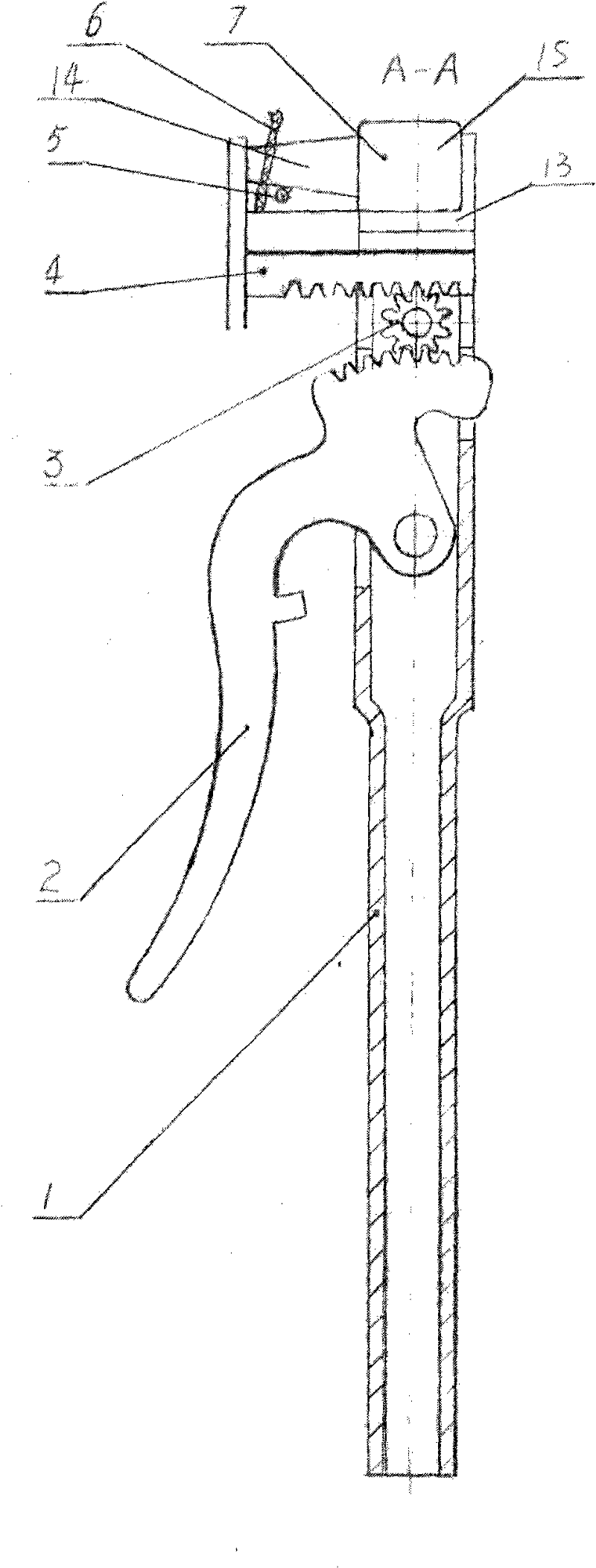

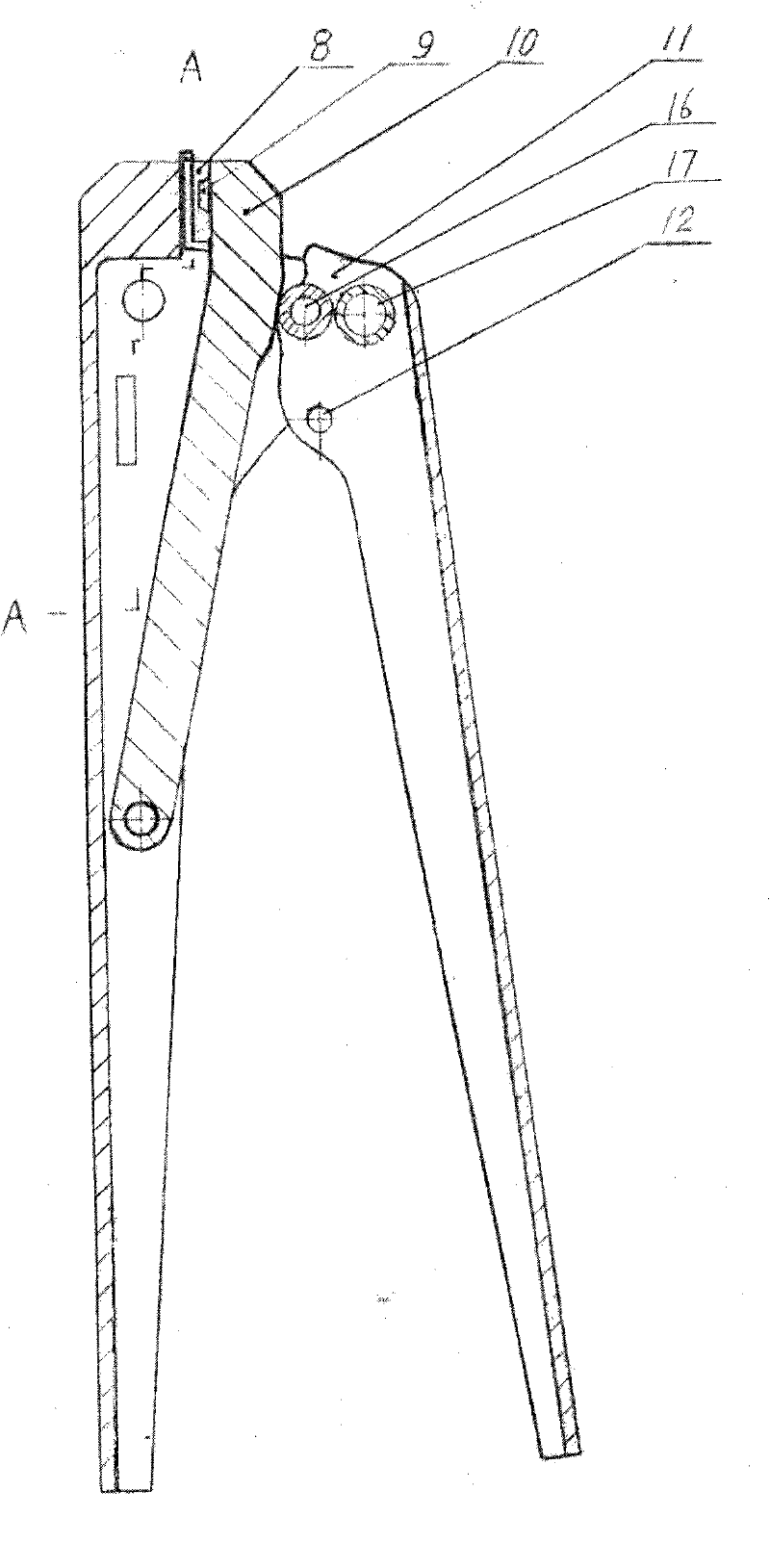

[0012] Example: such as figure 1 , 2 , this metal crimping type seal clamp includes a pliers body 10, a main handle 1 connected to the pliers body 10, an auxiliary handle 11 that can press the pliers body 10, and the auxiliary handle 11 is connected to the pliers body 10 through a pivot pin 17. On the top, the top of the auxiliary handle 11 is provided with a pressure wheel 16, the auxiliary handle 11 is provided with a positioning pin 2 12 that acts as a limit, the main handle 1 is provided with a small handle 2, and the small handle 2 is equipped with a handle that can drive the movable block 4 to move. Gear 3, the top of the main handle 1 is provided with a fixed block 13, the top of the main handle 1 is provided with a positioning pin 5 that acts as a limit to the movable block 4, and the top of the pliers body 10 is provided with a small bump 9 and Die 8 that plays the role of embossing.

[0013] When in use, the flat part 15 of the metal rolling seal 7 bears against th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com